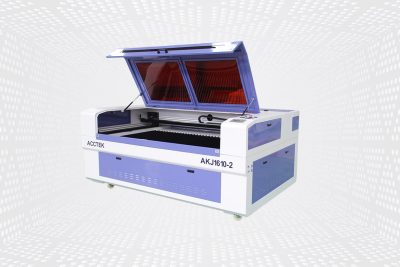

Wood Laser Cutting Machine

Product Range

-

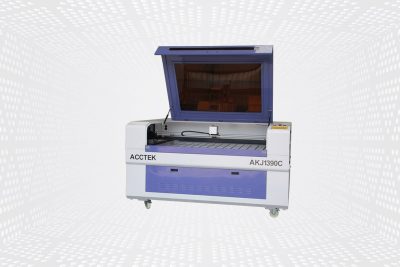

MDF Laser Cutting Machine

Rated 5.00 out of 5$2,700.00 – $8,000.00 Select options This product has multiple variants. The options may be chosen on the product page -

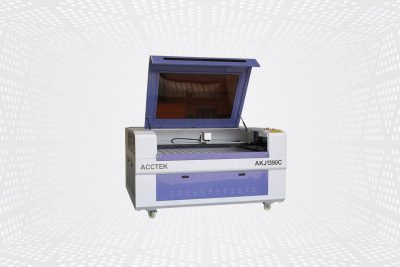

Plywood Laser Cutting Machine

Rated 4.75 out of 5$2,700.00 – $8,000.00 Select options This product has multiple variants. The options may be chosen on the product page -

Timber Laser Cutting Machine

Rated 4.75 out of 5$2,700.00 – $8,000.00 Select options This product has multiple variants. The options may be chosen on the product page -

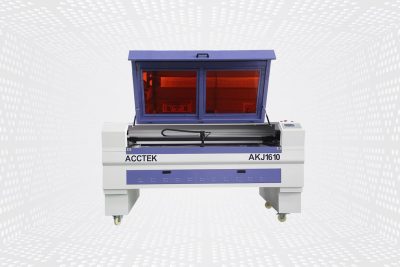

Veneer Laser Cutting Machine

Rated 4.75 out of 5$2,950.00 – $8,000.00 Select options This product has multiple variants. The options may be chosen on the product page -

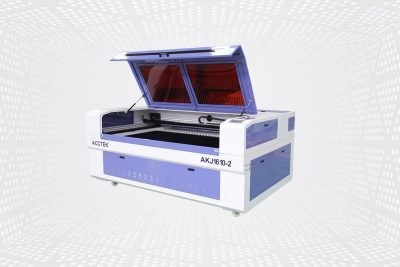

Balsa Wood Laser Cutting Machine

Rated 4.75 out of 5$2,700.00 – $8,000.00 Select options This product has multiple variants. The options may be chosen on the product page

Laser Cutting VS. Other Methods

Laser Cutting vs. Mechanical Cutting

Laser cutting provides smoother, more accurate cuts with fewer burrs and minimal post-processing. Mechanical cutting, on the other hand, can cause rough edges and may require additional finishing. Additionally, laser cutting doesn’t involve tool wear, unlike mechanical methods, reducing maintenance costs.

Laser Cutting vs. Waterjet Cutting

Water jet cutting is effective for thicker materials but is slower than laser cutting and produces larger kerfs. Laser cutting provides faster processing, cleaner cuts, and requires less post-processing, making it ideal for detailed designs in wood. Water jet machines also have higher operating costs.

Laser Cutting vs. CNC Routing

While CNC routing is great for cutting larger, thicker wood pieces, laser cutting offers more precision and the ability to engrave intricate patterns. Laser cutting produces finer, cleaner edges without tool wear, making it a more cost-effective solution for detailed and smaller cuts.

Why Choose AccTek Laser

Cutting-Edge Technology

AccTek Laser machines utilize the latest laser technology, ensuring high precision and fast cutting speeds. Our systems provide unmatched accuracy and efficiency, ensuring the best quality cuts across various materials with minimal distortion.

Custom Solutions

We understand that every business has unique requirements. That's why we offer customizable options, including power ranges, work area sizes, and cutting speeds, allowing you to tailor our machines to fit your specific production needs and material types.

Exceptional Energy Efficiency

Our laser cutting machines are designed for maximum energy efficiency. With lower power consumption and optimized performance, AccTek Laser machines help reduce operational costs, making them a cost-effective solution for both small and large-scale manufacturing.

Durability and Reliability

AccTek Laser cutting machines are engineered for long-term durability, with high-quality components and precision manufacturing. Our machines are designed to provide consistent, reliable performance, reducing maintenance needs and extending the lifespan of your equipment.

After-Sales Support

We believe in building long-term relationships with our customers. AccTek Laser provides exceptional after-sales support, including installation, training, and ongoing technical assistance. Our team is always ready to help you optimize machine performance and resolve any issues quickly.

Competitive Pricing and Value

At AccTek Laser, we offer high-performance laser-cutting machines at competitive prices, ensuring that you get the best value for your investment. Our machines deliver outstanding quality at an affordable cost, making us a trusted partner for your manufacturing needs.

Frequently Asked Questions

Can Lasers Cut Wood?

What Is The Cutting Accuracy of Wood Laser-Cutting Machines?

What Types of Wood Can Lasers Cut?

- Plywood

- Plywood is a popular choice for laser cutting because it consists of thin layers of wood veneers, often bonded together using adhesives that respond well to laser cutting. It cuts cleanly and produces sharp edges.

- MDF (Medium Density Fiberboard)

- MDF is an engineered wood product composed of wood fibers, waxes, and resins compressed into dense sheets. It cuts well with a laser and produces smooth edges. However, the fumes produced during the cutting process can be more toxic than natural wood, so proper ventilation is required.

- Hardwood

- Maple: Maple is a popular choice for laser cutting because of its fine grain and consistent density.

- Cherry Wood: Cherry wood cuts well with lasers and has a beautiful reddish-brown color.

- Walnut: Another hardwood that can be laser cut cleanly, walnut is known for its rich, dark color.

- Birch: Birch plywood is often used for laser cutting because it has a smooth surface and cuts well.

- Corkwood

- Pine: Pine is one of the softer woods and can be easily cut with a laser. Some resin may be produced during cutting, which will affect the laser optics.

- Cedar: Cedar is known for its pleasant aroma and is suitable for laser cutting.

- Rosewood: Rosewood is a softwood that can be laser-cut and has a distinct reddish hue.

- Exotic Woods

- Some exotic woods, such as rosewood, zebrawood, and wenge, can also be laser cut, but laser settings may need to be adjusted due to changes in density and hardness.

What Are The Disadvantages of Laser Cutting Wood?

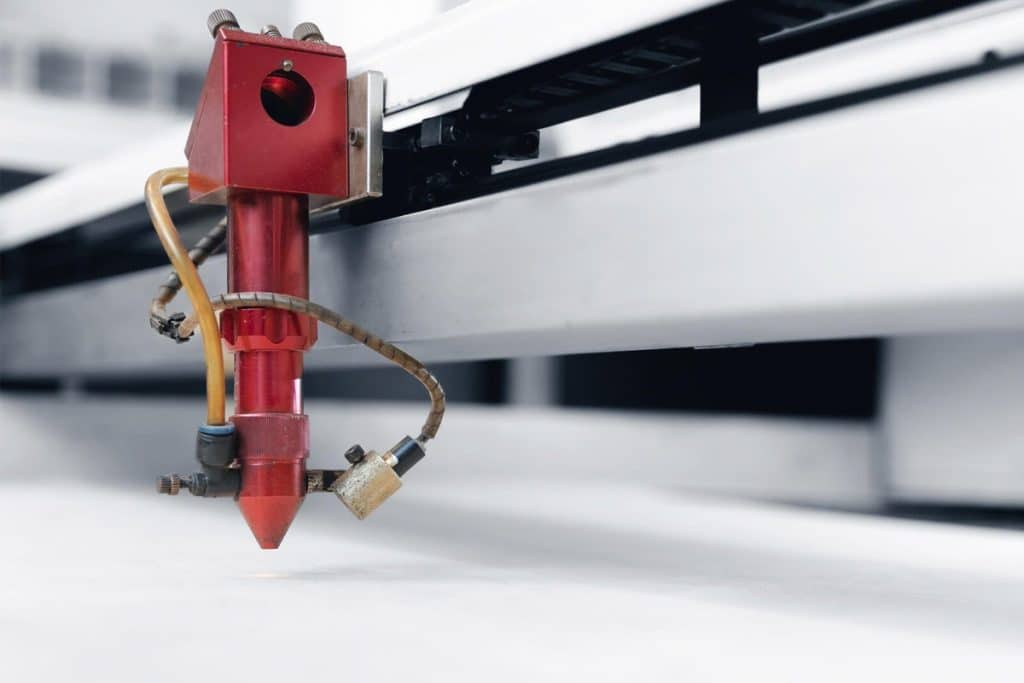

- Wavelength: The operating wavelength of the CO2 laser generator is 10.6µm. This wavelength of light can be highly absorbed by organic materials such as wood, which makes it very efficient in wood cutting and engraving.

- Power Range: CO2 laser generators are available in a variety of power levels, from low-power laser generators (such as 20W) for fine engraving to high-power laser generators (such as 400W or higher) for thick wood cutting. The choice depends on the thickness of the wood and the cutting speed required.

- Versatility: CO2 laser generators can cut a variety of wood types and thicknesses with excellent accuracy and minimal charring. Its ability to cut complex designs, curves, and straight lines makes it ideal for a variety of woodworking applications.

- Control and Precision: CO2 laser generators provide excellent control and precision for intricate and detailed designs in wood cutting. It can be cut with high precision and is suitable for artistic and intricate applications.

- Cost-Effectiveness: CO2 laser generators are generally more cost-effective than some other laser generator types, and this capability makes them a practical choice for many woodworking and small to medium-sized businesses.

- Ease of Maintenance: While CO2 laser generators do require some maintenance, they are generally considered reliable and have a longer lifespan when maintained correctly.

- Edge Quality: CO2 laser generators produce clean, smooth edges on wood that minimize the need for post-processing.

- Availability: CO2 laser generators and systems are readily available from a variety of manufacturers, offering a variety of options to suit different cutting needs.

How Much Do Wood Laser-Cutting Machines Cost?

- Entry-Level Wood Laser Cutting Machine: Small entry-level desktop laser cutting machines suitable for hobbyists and small projects typically start at around $1,000 to $3,000. These machines typically have lower power (e.g. 20W to 60W) and a smaller cutting area.

- Mid-Range Wood Laser Cutting Machine: Mid-range wood laser cutting machines with higher power (such as 80W to 150W) and larger cutting areas typically cost $3,000 to $15,000. These machines are suitable for small businesses and workshops.

- High-End Wood Laser Cutting Machine: High-end wood laser cutting machines with higher power (such as 150W and above), larger bed sizes, and advanced features range in price from $8,000 to $50,000. These machines are suitable for industrial and production-level applications.

Is Laser Cutting Wood Safe?

- Protective Equipment: Wear appropriate protective equipment, including safety glasses or goggles designed specifically for laser use, to protect your eyes from the powerful laser. Depending on the laser power and potential for smoke, additional personal protective equipment such as a lab coat or face shield may be required.

- Ventilation and Air Filtration: Laser-cutting wood produces fumes that may contain particulate matter and potentially harmful chemicals. Adequate ventilation and air filtration systems help remove and filter these emissions to maintain air quality.

- Consumer Safety: Wood can catch fire when exposed to high-power laser beams, make sure your workspace is equipped with a fire extinguisher and other fire safety equipment. Operators should pay close attention to the laser-cutting process to prevent fires.

- Material Compatibility: Some woods may contain chemicals or finishes that produce toxic fumes when laser cut. Make sure you use safe, non-toxic wood materials and be aware of any potential hazards associated with the wood itself.

- Maintenance: Regularly maintain and inspect your laser cutting machine to ensure that all safety features, such as interlocks and emergency stop buttons, are working properly. It is recommended to follow the manufacturer’s recommended maintenance schedule.

- Training: Make sure anyone operating the laser cutter is adequately trained in safe use and operation. Training should cover machine-specific safety protocols, emergency procedures, and proper laser handling.

Are There Any Special Ventilation Requirements for Wood Laser-Cutting Machines?

- Exhaust System: Wood laser-cutting machines should be equipped with a robust exhaust system that effectively captures and removes smoke and fumes generated during the cutting process. This system typically includes a powerful fan or blower that draws the air and contaminants through a ducting system and expels them outside or through a filtration system.

- Filtration: In addition to simply exhausting the air outside, some wood laser-cutting machines may utilize filtration systems to remove harmful particulates and odors from the air before recirculating them back into the workspace. These filtration systems may include activated carbon filters or other types of air purification technology.

- Ventilation Setup: Correct setup of the ventilation system ensures effective removal of fumes from the cutting area. This may involve positioning the exhaust vents strategically to capture the contaminants as close to the cutting point as possible and ensuring adequate airflow throughout the workspace.

- Compliance with Regulations: Depending on the jurisdiction and the type of materials being processed, there may be regulations and guidelines regarding ventilation and air quality in industrial settings. You need to ensure that your wood laser cutting machine and ventilation system comply with these regulations to maintain a safe and healthy working environment.

What Safety Features Do Wood Laser-Cutting Machines Have?

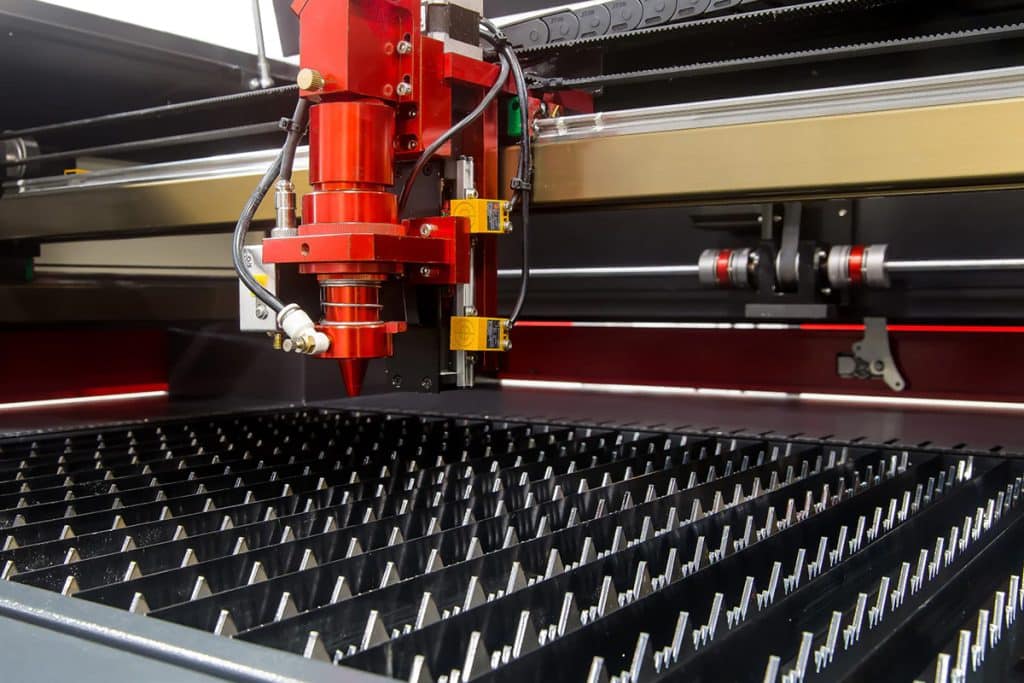

- Enclosure: Most wood laser-cutting machines come with a fully enclosed work area to prevent operators from coming into direct contact with the laser beam during operation. The enclosure also helps contain any smoke, fumes, or debris generated during cutting.

- Interlock Systems: Interlock systems ensure that the laser cannot operate unless all safety features are properly engaged. For example, the machine may have door interlocks that automatically shut off the laser when the enclosure door is opened. This prevents accidental exposure to the laser beam.

- Emergency Stop Button: An emergency stop button is a prominent, easily accessible feature on wood laser-cutting machines. Pressing this button immediately halts all machine operations in case of an emergency or when safety concerns arise.

- Beam Shielding: Beam shielding devices, such as beam blocks or curtains, are installed around the cutting area to prevent the laser beam from escaping and potentially causing harm to operators or bystanders.

- Automatic Laser Power Adjustment: Some advanced wood laser-cutting machines are equipped with sensors that automatically adjust the laser power based on the material being processed. This helps prevent overheating and ensures consistent cutting results while minimizing the risk of fire.

- Cooling Systems: Laser systems generate heat during operation, so cooling systems are essential to prevent overheating. These systems may include water or air cooling mechanisms to maintain safe operating temperatures.

- Safety Interlocks with Exhaust System: Laser-cutting machines often have safety interlocks that ensure the exhaust system is operating before the laser can be activated. This helps to prevent the buildup of smoke and fumes in the work area, which can pose health hazards.

- Training and Safety Protocols: Operators of wood laser-cutting machines should receive comprehensive training on safe operation and maintenance procedures. Additionally, the machines may come with safety manuals and protocols outlining best practices for safe use.

Related Resources

Can a CO2 Laser Cutting Machine Perform Cutting and Engraving Tasks at the Same Time?

Can CO2 laser cutting machines achieve “multi-purpose use” of precise cutting and fine engraving? This article combines the principle with the functional characteristics of AccTek’s CO2 laser cutting machines to

Do Fiber Laser Generators Lose Power over Time?

This article focuses on the reasons why fiber laser generator power decreases over time and proposes effective strategies to mitigate power loss through high-quality equipment, regular maintenance, and an optimized

How Does a CO2 Laser Cutting Machine Achieve High-Precision Cutting?

This article mainly introduces the principles and key technologies behind the high-precision cutting capabilities of CO2 laser cutting machines, and analyzes their core structural components and advantages.