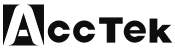

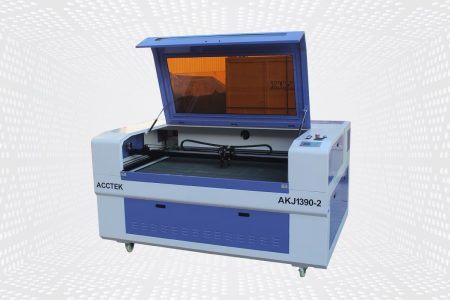

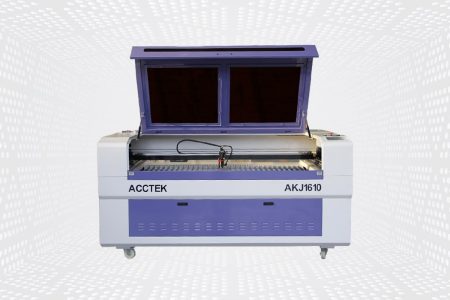

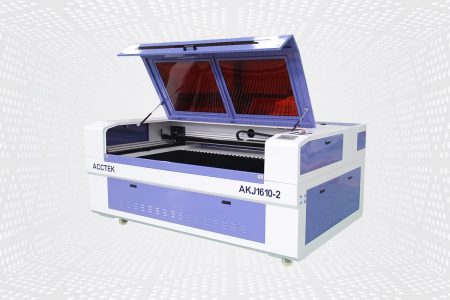

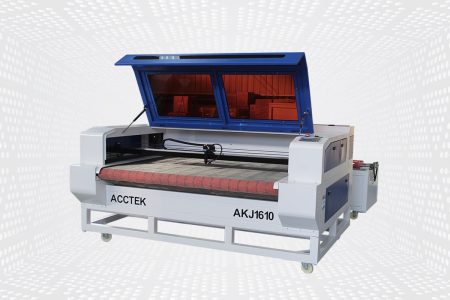

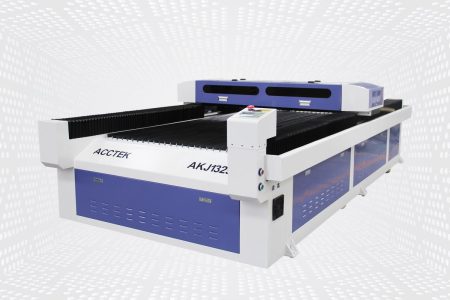

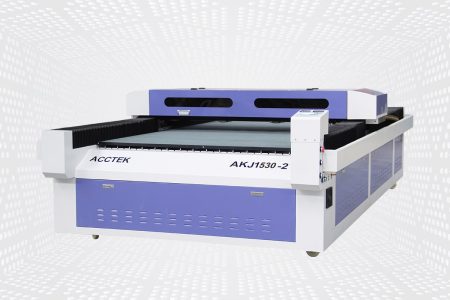

AccTek Laser Cutting Machine

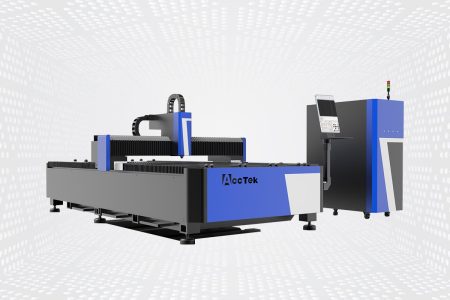

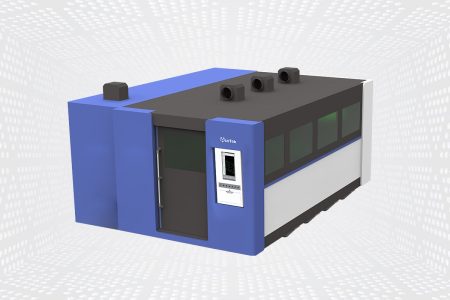

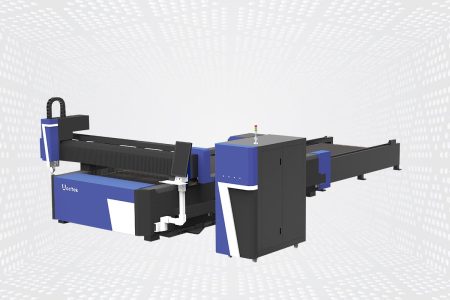

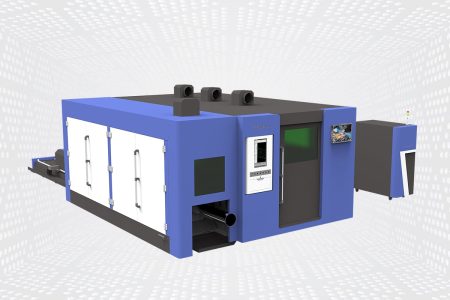

Laser cutting machines are specialized tools that use a focused beam of light to cut various materials. The process of cutting materials with a laser is called laser cutting and is used in various manufacturing and industrial applications. The process is so precise that laser cutting machines can cut complex shapes and intricate designs with high precision. Laser cutting machines have become one of the most versatile and affordable metalworking workpieces. Laser cutting machines can cut metal and non-metal materials of different thicknesses using only a laser beam and auxiliary gas. Laser cutting machines provide excellent edge finish and breakneck cutting speeds for metals and non-metals. AccTek’s laser cutting machines come in a wide range of standard options including, but not limited to, fully enclosed protective covers and sizes to suit any metal or non-metal processing need.

Mixed laser cutting machines are the newest type of laser cutting machines available and are a combination of fiber optic and CO2 laser cutters. The combined use of the two lasers allows them to cut a variety of materials with greater precision and faster speed than other types of laser cutting machines. Mixed laser cutting machines are more expensive than other types of laser cutting machines, but their cutting accuracy and cutting efficiency will be greatly improved. Mixed laser cutters are ideal for large-scale manufacturing. They are also capable of cutting a wide variety of materials, making them ideal for a variety of industries. Additionally, mixed laser cutting machines are relatively low maintenance and can be used in a wide range of applications.

Advantages of Laser Cutting Machine

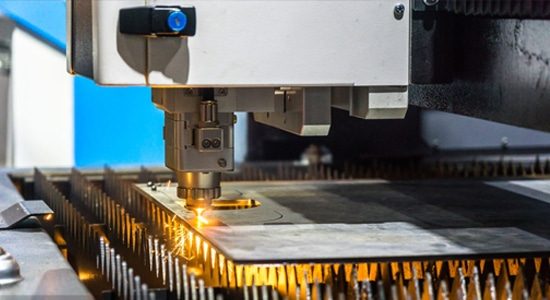

High Cutting Precision

High Cutting Precision

Fast Cutting Speed

Fast Cutting Speed

Versatility

Versatility

Cost Effectiveness

Cost Effectiveness

Automation

Automation

Better Cutting Quality

Better Cutting Quality

Versatility

Versatility

Better Cutting Quality

Better Cutting Quality

Frequently Asked Questions

Laser cutting machines have different types of laser generators, and different types of laser generators can cut different materials.

- Fiber laser cutting machine: It can cut all types of metals, from mild steel to stainless steel, and also non-ferrous metals. Highly reflective metals such as aluminum and copper are more difficult to cut.

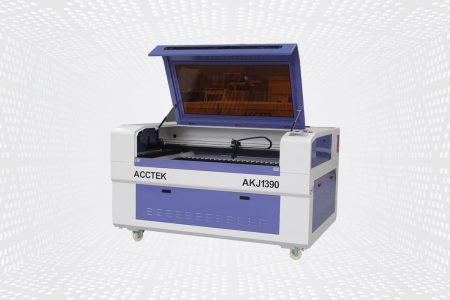

- CO2 laser cutting machine: It can cut wood, cardboard, leather, acrylic, glass, and other non-metallic materials.

- Neodymium Laser Cutting Machine: It is formed from crystals doped with neodymium, which can cut metal, plastic, and ceramics.

- Fire Hazard: Since the laser cutting process generates sparks and heat that may ignite combustible materials near the cutting area, it is important to keep combustible materials away from the laser cutting area.

- Smoke And Particles: According to the different materials to be cut, different harmful fumes and particles will be produced during laser cutting. Breathing in these fumes and particles can cause respiratory problems and other health issues, so it is important to use proper ventilation and safety equipment when operating a laser cutter.

- Eye Damage: Since the laser beam intensity used by the laser cutting machine is very high, laser cutting can cause damage to the eyes. Always wear protective glasses when operating the laser cutting machine.

- Skin Burns: The high temperature generated by the laser may burn the exposed skin.

- Noise: The laser cutting process produces very loud noises, which may cause hearing damage if proper ear protection is not used.

- Electrical Hazard: The operation of the laser cutting machine consumes a large amount of electricity and may cause electric shock if not handled properly. It is important to be aware of the potential electrical hazards when operating a laser cutter.

The biggest difference between a CNC machine and a laser cutting machine is how the cutting actually happens. CNC cutting works by friction, they use tools and drills to route the material. Laser cutting, on the other hand, cuts the material by emitting a hot laser beam. This is a key distinction, and it means that each type of machine has its own scenarios where it really comes into play.

Because laser cutting machines generate a lot of heat, they are not suitable for cutting certain materials. In some cases, the composition of the material itself makes it impossible for lasers to cut due to the risk of fire or toxic fumes.

- Polystyrene: Using laser cutting on this material will cause it to catch fire.

- Fiberglass: This material is made of glass and epoxy resin and produces toxic fumes when cut with a laser.

- Polycarbonate: Unless the material is very thin, other methods should be used to cut polycarbonate. Laser cutting is difficult to get a good finish on this material as it absorbs energy and discolors badly.

- HDPE And ABS: The heat from the laser cutter will vulcanize these materials, which means you won’t be able to get any type of clean edge. Plus, it’ll make a mess of your laser cutter.

- PVC: When using laser cutting, PVC will release a lot of toxic fumes. You should not use a laser cutter to cut any type of PVC.