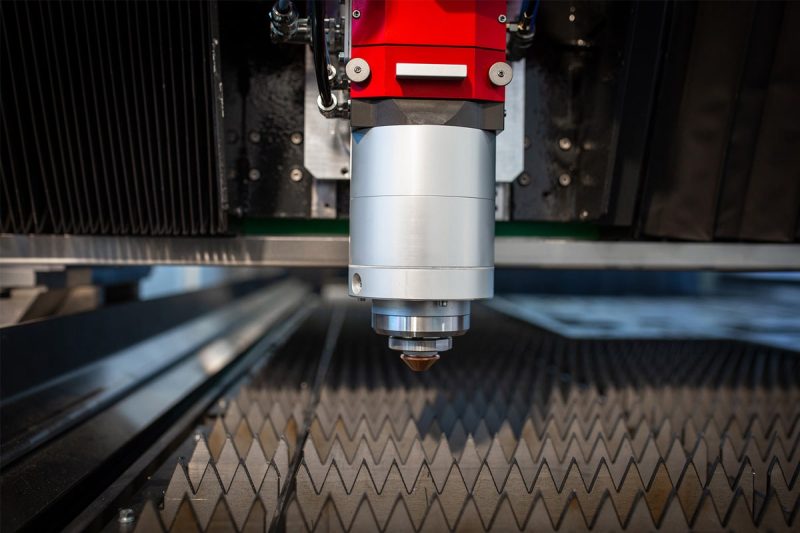

Motion System in Fiber Laser Cutting Machine

In the modern metal processing field, maszyny do cięcia laserem światłowodowym have become essential equipment for high-precision and high-efficiency manufacturing. Within the core structure of the entire machine, the motion system plays a crucial role. It controls the movement path of the cutting head along the X, Y, and Z axes, and its performance directly determines cutting accuracy, cutting speed, operational stability, and the overall lifespan of the machine. A high-performance motion system not only ensures accurate reproduction of the cut pattern but also maintains stable output at high speeds, making it key to achieving high-quality cutting results and improving production efficiency.

This article will delve into the four commonly used drive motor types in fiber laser cutting machines—servo motors, stepper motors, linear motors, and hybrid servo motors—systematically analyzing their differences in structural principles, control methods, dynamic response, positioning accuracy, and cutting speed. By comparing and analyzing the advantages and disadvantages of different motors and combining them with practical industrial application cases, this article will further guide readers on how to scientifically select the most suitable motor solution based on their own processing needs to optimize equipment performance, reduce maintenance costs, and lay a solid foundation for future intelligent manufacturing upgrades.

Spis treści

Silniki serwo

A servo motor is a motor system that employs closed-loop feedback control. It typically uses a high-resolution encoder or resolver to continuously monitor the actual position/velocity. The controller compares this to a set target, dynamically adjusting the motor’s output to maintain precise motion. Its structure usually features low rotor inertia, high torque density, and fast response, making it ideal for high-performance machining equipment.

In the motion systems of fiber laser cutting machines, servo motors are commonly used in mid-to-high-end models, especially when the equipment demands high performance in terms of response speed, acceleration, trajectory accuracy, repeatability, and cutting complex curves.

Impact on Cutting Accuracy:Because the servo system is a closed-loop control system, it can detect and adjust in real time any positional deviations during the cutting head’s movement (such as those caused by mechanical inertia, load fluctuations, rack backlash, guide rail vibration, etc.), significantly improving trajectory accuracy and repeatability.

During laser cutting, especially when executing curves, complex shapes, or rapid direction changes, the servo motor’s high response speed and torque maintenance capability better handle inertia changes and sudden load changes, thus reducing cutting errors, improving cutting edge quality, and minimizing burrs and jagged edges.

Compared to traditional open-loop systems (such as stepper motors without feedback), servo motors almost never experience “step loss” or “step derailment.” This means that trajectory deviations are effectively controlled during high-speed movement or heavy-load start/deceleration, improving product consistency and processing quality.

Impact on Cutting Speed:High-performance servo motors possess excellent acceleration/deceleration capabilities and the ability to maintain torque output at high speeds. This enables fiber laser cutting machines to achieve faster movement speeds and shorter idle travel times in the motion system.

Faster acceleration means reduced delay in the cutting head moving from one position to the next, directly shortening the cutting cycle and increasing the processing volume per unit time. Combined with appropriate trajectory optimization and reversing strategies, overall production efficiency can be significantly improved.

Especially in high-speed trajectory cutting scenarios (such as curve cutting, multi-point reversing, and automatic material changing), servo motors are more advantageous than stepper motors because they maintain stable torque and high positioning accuracy even at high speeds, ensuring both improved cutting quality and efficiency.

Overall, servo motors play a crucial role in maszyny do cięcia laserowego. With their closed-loop control system and high-response characteristics, servo motors not only effectively improve cutting accuracy and repeatability but also maintain stable torque output at high speeds, significantly optimizing cutting speed and trajectory smoothness. For users seeking high-efficiency and high-precision processing, choosing a servo drive system is undoubtedly a key way to improve laser cutting performance.

Silniki krokowe

A stepper motor is an open-loop control motor system. Its principle is to precisely control the motor’s rotation angle and speed by controlling the number and frequency of current pulses. Each input pulse signal causes the motor shaft to rotate a fixed angle (i.e., the “step angle”), thus achieving high positioning accuracy without a feedback device. Stepper motors have a relatively simple structure, are low-cost, and are easy to control, making them a common motion-drive solution in low-to-medium-power fiber laser cutting machines and entry-level CNC cutting platforms.

The main types of stepper motors include permanent magnet (PM), reactive (VR), and hybrid (HB). Hybrid stepper motors are the most widely used, combining the advantages of PM and VR to provide higher torque density and smoother motion, and are suitable for small-to-medium format laser cutting machines, advertising cutting machines, and other equipment.

Impact on Cutting Accuracy: Stepper motors achieve position control by controlling the number of pulses, and their positioning accuracy is typically between 1.8° (200 steps/revolution) and 0.9° (400 steps/revolution) per step. In fiber laser cutting machines, this means its precision is sufficient for applications with lower precision requirements, such as thin plate cutting or graphic engraving. However, due to the lack of feedback control, the stepper system cannot correct for “missed steps” caused by load changes, mechanical damping, or acceleration inertia in real time. When the cutting head moves at high speed or accelerates/decelerates rapidly, the motor may become out of phase, leading to positional errors and affecting the continuity and edge quality of the cutting lines.

To improve this issue, modern control systems often employ microstepping technology, dividing a complete step distance into multiple smaller step angles, thereby achieving smoother motion and higher resolution, significantly reducing vibration and noise. Even so, stepper motors are still less stable than servo systems in complex trajectories and high-load environments.

Impact on cutting speed: The torque output of a stepper motor decreases sharply with increasing speed, meaning it is prone to insufficient torque at high speeds, thus limiting the maximum speed of the cutting machine. Generally, the optimal operating speed range for a stepper system is between 300–1000 rpm; beyond this range, motor performance will significantly degrade. Therefore, stepper-driven laser cutting machines are more suitable for low- to medium-speed cutting tasks, such as processing scenarios with low throughput requirements, such as stainless steel signs, wood panels, and small decorative parts.

Furthermore, stepper motors have a relatively slow response speed, making them unsuitable for frequent start-stop operations. If the cutting path contains many curves and sharp angle transitions, the system requires longer acceleration and deceleration times to avoid missing steps, which also limits overall cutting efficiency to some extent.

Overall, stepper motors still hold an important position in small and medium-sized fiber laser cutting machines due to their advantages of simple structure, convenient control, and low cost. They can provide sufficient positioning accuracy under low-speed, light-load conditions, making them suitable for entry-level or mid-range processing equipment. However, for applications requiring high-speed processing, complex trajectory control, and high repeatability, the performance limitations of stepper motors are more pronounced. For such applications, companies typically upgrade to servo systems or hybrid servo solutions to achieve higher dynamic response and precision control capabilities.

Silniki liniowe

A linear motor is a drive device that achieves linear motion without the need for mechanical transmission components (such as lead screws, gears, or belts). Its working principle is similar to an “expanded version” of a traditional rotary motor: electromagnetic induction directly generates linear thrust between the stator and mover, thereby driving the cutting head or worktable to move precisely along the guide rail. In fiber laser cutting machines, linear motor systems are commonly used in high-end, high-speed models, especially in industrial applications requiring high acceleration, high repeatability, and zero backlash.

Due to the elimination of mechanical contact structures, linear motors offer advantages such as fast response, low friction, good dynamic performance, and virtually zero maintenance. Typical accelerations can reach 1.5–3 G, maximum operating speeds exceed 200 m/min, and positioning accuracy can reach ±0.002 mm, making it one of the most advanced motion control solutions currently available for high-speed laser cutting machines.

Impact on Cutting Accuracy: The greatest advantage of linear motors lies in their contactless transmission characteristics. This means there is no mechanical backlash, gear error, or belt elastic deformation, thus achieving truly high-precision control. With a high-resolution optical encoder feedback system, the linear motor can detect and correct displacement errors in real time, achieving micron-level stability in the laser cutting head’s trajectory. This is particularly crucial for cutting complex curves, small holes, and sharp angles—high-precision workpieces—significantly improving the smoothness and consistency of the cut edges.

Furthermore, because the linear motor has no mechanical friction parts, it experiences virtually no wear during long-term operation and avoids the backlash problem common in traditional servo motors. Therefore, it maintains stable repeatability and positioning accuracy during long-term continuous processing.

Impact on Cutting Speed: The linear motor possesses extremely fast response and acceleration capabilities, making it the core power source for high-speed laser cutting systems. When performing complex trajectories or multi-segment cuts, the linear motor can start and stop in a very short time, significantly reducing transition time and thus improving overall production efficiency. Compared to traditional gear or lead screw drives, linear drives can shorten the cutting cycle by 30%–50%, especially excelling in batch processing of thin plates, cutting electronic components, and manufacturing precision metal structures.

Furthermore, the acceleration and deceleration process of linear motors is smooth and virtually vibration-free, helping to reduce inertial deviation of the laser head during high-speed reversals, thus improving cutting accuracy and edge quality.

Linear motors are renowned for their high precision, high acceleration, and low wear, making them the highest-performance motion system solution for fiber laser cutting machines. Their contactless transmission design allows the equipment to maintain stable accuracy and consistency even at high speeds, making them an indispensable core drive technology in modern high-end industrial processing. Despite their higher cost and more complex control system, linear motors are undoubtedly the optimal solution for manufacturers seeking ultimate speed and precision.

Hybrid Servo Motors

Hybrid servo motors combine the high positioning resolution of stepper motors with the closed-loop control advantages of servo systems, often considered a compromise between the two. Structurally, they are based on a hybrid stepper motor design, with an encoder mounted on the motor shaft to form a closed-loop control system. When the system detects a position error, the controller automatically adjusts the current and phase, correcting the motor’s output in real time, achieving dynamic response and high precision performance similar to servo motors.

In fiber laser cutting machines, hybrid servo motors are commonly used in mid-range or cost-effective models, such as thin plate cutting machines, low-power laser platforms, and advertising production equipment. Their advantage lies in significantly improving the “step loss” and “vibration” problems of traditional stepper motors while maintaining low cost.

Impact on Cutting Accuracy: Hybrid servo motors employ a closed-loop control system that monitors the rotor position in real time and dynamically corrects deviations, thus significantly improving positioning accuracy and repeatability. During actual cutting, the system automatically compensates for errors caused by load fluctuations, inertial deviations, or mechanical loosening based on the position information fed back by the encoder, making the laser cutting head move more smoothly and the path more precise. Compared to traditional stepper motors, hybrid servo motors offer a 30-50% improvement in precision, with repeatability typically controlled within ±0.01 mm, sufficient for most medium-precision metal processing tasks.

Furthermore, the microstepping drive technology and self-tuning control algorithm of hybrid servo motors significantly reduce resonance and noise at low speeds, resulting in smoother cutting edges and reduced mechanical vibration during processing.

Impact on cutting speed: The dynamic response speed of hybrid servo motors falls between that of traditional stepper motors and servo systems, offering high start-stop acceleration and stable torque output. Their torque curve decays slowly in the medium-to-high speed range, maintaining effective driving force at higher speeds, allowing laser cutting machines to maintain smooth operation even when performing long-stroke cuts or frequent acceleration/deceleration tasks.

The biggest advantage of hybrid servo systems compared to stepper motors lies in their automatic anti-step-loss mechanism. When overload or phase error is detected, the control system immediately compensates, ensuring a complete and accurate cutting path and avoiding waste or rework. This characteristic makes hybrid servo systems particularly suitable for equipment solutions requiring high production efficiency but with limited costs. Hybrid servo motors achieve a good balance between performance and cost.

They retain the high resolution and ease of control of stepper motors while compensating for their shortcomings in accuracy and stability through closed-loop feedback, making them an ideal drive choice for mid-range fiber laser cutting machines. For users seeking high cost-effectiveness and improved cutting stability and accuracy, hybrid servo systems are a motion control solution worth considering.

Comparison of Different Motors

In the motion system of a fiber laser cutting machine, servo motors, stepper motors, linear motors, and hybrid servo motors each possess unique structural characteristics and application positioning. Different types of motors directly determine the speed performance, positioning accuracy, system cost, and maintenance complexity of the cutting equipment. Understanding the differences between these motors helps companies make more informed decisions during equipment design or procurement.

Firstly, from a control perspective, both servo motors and hybrid servo motors belong to closed-loop control systems, capable of real-time monitoring of motor position and error correction; while traditional stepper motors are open-loop control, relying on the number of pulses to determine the movement position, lacking real-time feedback. Linear motors are also closed-loop control, but due to their direct drive, they have virtually no mechanical backlash or transmission error, giving them an absolute advantage in control accuracy.

In terms of cutting accuracy and repeatability, linear motors are renowned for their micron-level accuracy and extremely low error, making them the first choice for high-end laser cutting machines. Servo motors are second, with repeatability typically reaching ±0.005 mm, meeting most industrial-grade metal processing requirements. While hybrid servo motors are slightly less efficient than servo systems, they are significantly superior to stepper motors, maintaining stable accuracy within ±0.01 mm. Stepper motors perform well under low-speed and light-load conditions, but their accuracy is easily affected in high-dynamic processing or heavy-load environments.

From the perspective of motion speed and acceleration, linear motors possess the highest dynamic performance, with accelerations typically reaching 1.5–3 G, far exceeding traditional motor structures. Servo motors excel in high-speed response and torque output, making them suitable for machines requiring high-speed cutting and complex curve processing. Hybrid servo motors offer medium-speed performance, balancing stability and cost, while stepper motors, due to significant torque attenuation, are generally suitable for low-speed or medium-speed cutting equipment.

From the perspective of cost and system complexity, stepper motors, due to their simple structure and low driver cost, remain widely used in entry-level laser cutting equipment. Hybrid servo motors strike a balance between price and performance, making them a common choice in mid-range models. Servo motor systems are more expensive, but their superior accuracy and speed performance lead to their widespread use in mid-to-high-end equipment. Linear motors, due to their highest cost and complex control systems, are primarily used in high-speed, precision laser cutting machines that prioritize ultimate performance.

From a maintenance and lifespan perspective, stepper and servo systems rely on mechanical transmission structures (such as lead screws, gears, or belts), which are subject to wear. Linear motors, however, have no mechanical contact, requiring almost no maintenance and resulting in a significantly longer lifespan. Hybrid servo systems still have mechanical components, but their closed-loop control reduces stress impact, making them relatively more durable.

In summary:

- Stepper motors are suitable for low-cost, low-speed processing equipment.

- Hybrid servo motors are suitable for mid-range models that prioritize cost-effectiveness.

- Servo motors are the mainstream configuration for high-precision and high-speed cutting.

- Linear motors represent the highest level of motion control in laser cutting machines.

The choice between different types of motors is essentially a balance between cost, precision, and speed. For most metal processing companies, servo or hybrid servo systems achieve an ideal combination of performance and economy. However, when the production target is high-speed, ultra-precision, or long-term continuous operation, linear motors are undoubtedly the best solution. By fully understanding the characteristics and applicable scenarios of various motors, manufacturers can achieve the optimal combination of performance maximization and return on investment in the design and configuration of fiber laser cutting machines.

Jak wybrać odpowiedni silnik

When configuring a fiber laser cutting machine, selecting the correct motor type is crucial for ensuring system performance, accuracy, and reliability. Different applications have varying requirements for motor control precision, dynamic response, and load characteristics. The following are key steps and evaluation points for systematically selecting a motor:

Understanding Application Requirements

First, clearly define the main purpose and processing target of the laser cutting equipment, including material type, thickness, cutting trajectory complexity, and production cycle requirements. For example, high-speed cutting of thin plates or processing of complex shapes typically requires servo or linear motors with high acceleration and precision, while lighter-load applications such as advertising signage and acrylic cutting can utilize more cost-effective stepper systems.

A thorough understanding of application characteristics helps narrow down the selection and ensures that the chosen motor meets actual production needs.

Defining Performance Specifications

Motor performance indicators such as torque, speed, acceleration, and positioning accuracy must precisely match the equipment requirements. If the cutting task frequently involves high-speed starts and stops or complex trajectories, it is recommended to prioritize servo or linear motors for better dynamic response.

Furthermore, defining these parameters helps in the rational selection of subsequent drivers, control systems, and transmission mechanisms, avoiding system overload or insufficient performance issues.

Consider Environmental Factors

Motors are affected by external factors such as temperature, dust, humidity, and vibration in different working environments. For example, in metal cutting environments with high dust and heat levels, servo or linear motor systems with good encapsulation and strong heat dissipation should be prioritized.

Furthermore, the motor’s protection rating (IP rating) and long-term stability should be considered to ensure reliable operation of the equipment in high-temperature and high-dust environments.

Calculate Power Requirements

The power of the motor and drive system must match the overall load capacity and energy configuration of the equipment. Parameters such as motor starting current, peak power, and continuous operating current should be comprehensively considered to avoid insufficient power or excessive energy consumption.

Correct power calculations not only improve the energy efficiency ratio but also prevent system overheating and electrical faults, thereby extending the equipment’s lifespan.

Evaluate Control Options

The motor’s control method directly affects cutting accuracy and the smoothness of the motion trajectory. For example, a closed-loop servo control system can achieve precise feedback and error correction, while an open-loop stepper system is suitable for cost-sensitive scenarios. The appropriate control method should be selected based on the processing complexity and accuracy requirements, and compatibility between the controller, driver, and motor should be ensured.

Assessing Installation and Integration Requirements

When selecting a motor, assess its installation method within the equipment structure, dimensional compatibility, and compatibility with the transmission system (such as lead screws, racks, or guide rails). Servo and linear motors typically require a high-precision installation environment and rigid support structure to fully realize their performance. Proper mechanical integration effectively reduces vibration, runout, and other errors, ensuring a stable and reliable cutting path.

Reviewing Costs and Budget Constraints

The costs of different types of motors vary significantly and should be balanced based on project budget and performance goals. Stepper motors offer a good cost advantage, while servo and linear motors demonstrate greater benefits in high-performance applications. Allocating the budget appropriately can optimize the overall system’s cost-effectiveness without sacrificing core performance.

Consulting Suppliers and Experts

Technical communication with motor manufacturers or system integrators can provide more accurate selection advice and performance data. Experienced suppliers can recommend the most suitable motor type and drive solution based on load curves, motion trajectories, and cutting accuracy requirements. This professional guidance effectively reduces later debugging risks and shortens the project implementation cycle.

Testing and Verification

Before final production deployment, motor performance must be verified through actual operational testing, including acceleration response, thermal stability, and positioning accuracy. By comparing experimental data with expected indicators, it can be confirmed whether the motor can stably meet production requirements. If necessary, multiple rounds of verification and parameter optimization should be conducted to ensure long-term reliable and efficient operation of the equipment.

Choosing the right motor is not only a technical issue but also a core decision affecting the overall performance and production efficiency of the fiber laser cutting machine. Through systematic analysis of application requirements, performance parameters, and environmental conditions, combined with budget and professional advice, enterprises can achieve optimal equipment configuration.

The ultimate goal is to achieve a balance of high precision, high speed, and high stability, enabling laser cutting equipment to maintain a leading edge in the highly competitive manufacturing market.

Streszczenie

In fiber laser cutting machines, selecting the appropriate motion system motor is a key factor determining overall machine performance. From low-cost, simple stepper motors to high-performance, high-precision servo and linear motors, each solution has its unique application scenarios. For users with limited budgets but seeking higher stability, hybrid servo motors offer an ideal balance between performance and cost. Generally speaking, if your processing needs prioritize high speed, high precision, or large-format cutting, servo or linear motors are superior solutions; while for small-batch or standard sheet metal cutting, stepper or hybrid servo systems are perfectly adequate.

We understand the importance of motion system configuration to cutting quality and production efficiency. Based on different customers’ processing scenarios and budget requirements, we equip each laser cutting machine model with the most suitable motor and drive solutions, ensuring the machine achieves the optimal balance between performance and cost. Whether you focus on high-speed production, complex pattern processing, or seek a cost-effective general-purpose cutting solution, Laser AccTek can provide you with professional selection advice and customized support to help your processing business achieve more efficient and precise production results.

Informacje kontaktowe

- [email protected]

- [email protected]

- +86-19963414011

- Nr 3 Strefa A, strefa przemysłowa Lunzhen, miasto Yucheng, prowincja Shandong.

Uzyskaj rozwiązania laserowe