Why Are Pulsed Lasers More Powerful?

Pulse laser is a laser technology that releases a large amount of energy in a very short time. Unlike traditional continuous wave (CW) lasers, pulse lasers can provide up to thousands of times the peak power in a very short time interval. The unique characteristics of this laser technology have made it widely used in many fields, especially in precision machining, medical treatment, communication technology, and scientific research. The high energy output of a pulse laser enables it to perform high-precision machining and cutting, providing stronger material processing capabilities, while also having a lower heat-affected zone, avoiding the thermal damage that may be caused by conventional laser technology.

This article will explore the scientific principles of pulsed lasers in detail and analyze how to increase power through energy concentration, pulse duration, and repetition rate adjustment. At the same time, it will also explore the advantages of pulsed lasers in terms of precision, control, and versatility and how they can improve work efficiency and precision in different application scenarios. The article will also analyze the technical factors that need to be considered in pulsed laser design, such as pulse duration, energy storage, beam quality, and cooling system. Finally, this article will also evaluate the practical applications of pulsed lasers in industrial manufacturing, medical treatment, scientific research, and other fields, and discuss the challenges they face and future development directions.

Spis treści

Introduction to Pulsed Laser Cleaning

Pulsed laser is a laser technology that can release a large amount of energy in a very short time, usually with a pulse duration of picoseconds (ps) or femtoseconds (fs). Unlike traditional continuous wave (CW) lasers, pulsed lasers act on target objects with extremely high peak power and achieve efficient energy transfer in an instant through short laser pulses. A notable feature of pulsed lasers is their high repetition rate, which enables high-energy pulses to be continuously released in a short period, thereby producing a strong and precise effect on materials or targets in a short period.

This unique pulse characteristic gives pulsed lasers a clear advantage in many high-precision applications, especially in the fields of micro-machining, surface treatment, and precision cutting. Pulsed lasers can precisely control the transfer of energy, reduce the heat-affected area of surrounding materials, avoid the thermal damage that may be caused by traditional lasers, and achieve higher precision and more detailed processing effects. Due to their high peak power, pulsed lasers are also widely used in medical treatment, scientific experiments, communications, and other fields, providing important support for various technologies.

The Science Behind Pulsed Laser Power

The key reason why pulsed lasers can provide peak powers far higher than continuous wave (CW) lasers is their unique energy transfer mechanism. By releasing energy in a concentrated manner in a short period, pulsed lasers can achieve extremely high instantaneous power, enabling them to demonstrate excellent performance in fields such as precision machining, material processing, and scientific research. The core scientific principles that affect pulsed laser power mainly include energy concentration, pulse duration, repetition rate, and nonlinear effects, which together determine the performance and application range of pulsed lasers.

Energy concentration

Unlike continuous wave lasers, pulsed lasers do not output energy continuously but release high-energy pulses in a short period, thereby reaching extremely high peak power in a very short time. For example, if the average power of a laser generator is 100W and the pulse duration is only 10 nanoseconds (ns), then during each pulse, the peak power of the laser may be as high as thousands or even tens of thousands of watts. This energy concentration feature makes pulsed lasers outstanding in applications such as material micro-machining, laser marking, and precision welding and can efficiently remove materials while reducing the heat-affected zone.

Czas trwania impulsu

Pulse duration refers to the duration of a single laser pulse, usually measured in nanoseconds (ns), picoseconds (ps), or even femtoseconds (fs). The shorter the pulse duration, the higher the energy density per unit time, so short-pulse lasers can achieve more precise energy control. For example, in femtosecond laser processing, ultrashort pulses can directly act on the surface of a material, causing it to vaporize instantly without causing significant thermal damage to the surrounding area. This feature makes ultrashort pulse lasers have important application value in semiconductor manufacturing, medical surgery, and ultra-fine processing.

Współczynnik powtórzeń

Repetition rate refers to the number of laser pulses per unit time, usually in Hertz (Hz) or kilohertz (kHz). High repetition rate pulsed lasers can improve processing efficiency and make material processing more uniform and continuous. For example, in laser marking and micromachining, high repetition rate lasers can ensure continuous action on the material surface and reduce unevenness during processing. In applications such as laser cleaning, different repetition rate settings can optimize the efficiency of removing contaminants while reducing damage to the substrate.

Nonlinear effects

When the energy density of a pulsed laser reaches a certain level, the material will produce nonlinear effects such as multiphoton absorption, self-focusing, and plasma formation. These nonlinear phenomena are particularly significant in ultrashort pulse laser processing, which can greatly increase the absorption rate of the material, thereby achieving more efficient laser-matter interaction. For example, in femtosecond laser micromachining, nonlinear absorption effects can accurately engrave microstructures inside transparent materials without affecting the surface. In addition, nonlinear effects also play an important role in technologies such as laser-induced plasma spectroscopy (LIBS), which can be used for material composition detection and elemental analysis.

The powerful performance of pulsed lasers comes from their concentrated energy, short pulse duration, high repetition rate, and unique nonlinear effects. These scientific principles work together to make pulsed lasers show a wide range of application value in precision machining, medical applications, scientific research, and industrial manufacturing. With the continuous advancement of laser technology, future pulsed lasers will achieve higher energy control, shorter pulse duration, and more stable processing effects, providing stronger technical support for advanced manufacturing and scientific exploration.

Advantages of pulsed lasers

Pulse lasers have demonstrated unparalleled advantages in many industries due to their unique working mode. Compared with traditional continuous wave (CW) lasers, pulse lasers can release high energy in a very short time, achieve more precise processing, and reduce thermal effects. This technical feature makes it widely used in precision manufacturing, medical, aerospace, scientific research, and other high-demand industrial fields. The following are the main advantages of pulse lasers.

Precision and control

Pulsed lasers can precisely control the release of energy in a very short time, making them excellent in micro-nano-level processing and manufacturing. For example, in the microelectronics and semiconductor industries, pulsed lasers can perform precision engraving, micro-hole drilling, and circuit repair without affecting the surrounding area. This highly controllable energy transmission ensures more precise processing results, making it an ideal tool for high-end manufacturing.

Reduce thermal damage

Since the pulse duration of a pulsed laser is extremely short (nanosecond, picosecond, or even femtosecond level), most of the energy acts on the material instantly, causing the material to be directly vaporized or plasmatized without causing excessive heat conduction. Therefore, pulsed lasers can effectively reduce the heat affected zone (HAZ) when processing delicate or heat-sensitive materials to avoid deformation, melting, or damage of the material. For example, in the fields of biomedicine and glass cutting, this feature of pulsed lasers makes it the preferred technology, which can minimize material damage while ensuring high precision.

High peak power

The high peak power of pulsed lasers enables them to easily process high-strength materials such as metals, ceramics, and composites. In an ultra-short time, the powerful instantaneous energy can quickly destroy the surface structure of the material, making the material removal process more efficient. For example, in applications such as laser micromachining, laser marking, and laser cleaning, high peak power can ensure faster processing speeds and better removal effects while reducing chemical or mechanical damage to the material.

Enhanced material interaction

Pulsed lasers can trigger the nonlinear optical effects of materials in a very short time, greatly increasing the material’s absorption rate of lasers. This feature is particularly important in transparent material processing, optical coating, and semiconductor industries. For example, in the process of femtosecond laser precision cutting, the interaction between the laser and the material is stronger so that fine structures can be formed inside transparent substrates (such as sapphire or glass) without affecting the surface. This unique material interaction mechanism gives pulsed lasers greater potential in the processing of complex materials.

Wszechstronność

Pulsed lasers are not limited to processing metal materials. They can also be used in a variety of different application scenarios, including medical surgery, 3D printing, laser welding, surface modification, and cultural relic restoration. For example, in the medical field, pulsed lasers can be used to cut tissues without causing damage to achieve delicate surgical operations; in cultural relic restoration, laser cleaning can remove pollutants and oxide layers without damaging the original surface. In addition, in the aerospace and defense fields, the high-energy characteristics of pulsed lasers are also used for precision processing and material testing.

The unique advantages of pulsed lasers include extremely high precision and controllability, minimized thermal damage, high peak power, enhanced material interaction, and wide applicability. These features make them an important tool in industries such as precision manufacturing, medical, aerospace, and scientific research. With the continuous development of technology, the application scope of pulsed lasers will be further expanded, bringing more innovations and breakthroughs to high-end manufacturing and cutting-edge technology.

Technical Considerations in Pulsed Laser Design

The design of pulsed lasers involves several key technical parameters, which determine the performance, applicable scenarios, and processing effects of the laser generator. In the fields of industrial manufacturing, medical treatment, communication, and scientific research, the rational optimization of these technical parameters can improve the stability and efficiency of the laser generator and ensure its stable operation in various complex environments. The following are several technical factors that need to be considered in the design of a pulsed laser.

Pulse duration and repetition rate

Pulse duration refers to the length of time each pulse laser is released, usually in nanoseconds (ns), picoseconds (ps) or femtoseconds (fs). Short pulse time can reduce the heat affected zone (HAZ) and ensure more precise processing results, especially suitable for micro-machining and medical applications.

Repetition rate refers to the frequency of laser pulse emission, usually in Hertz (Hz) or kilohertz (kHz). A higher repetition rate can improve processing efficiency, but if the energy distribution is uneven, it may affect the processing quality. Therefore, when designing a pulsed laser generator, it is necessary to balance the pulse duration and repetition rate to ensure that both high precision and stable processing efficiency can be achieved. For example, in precision cutting or micromachining applications, femtosecond lasers usually use a combination of short pulse time and high repetition rate to achieve higher processing quality.

Energy storage and release

The working principle of pulsed lasers involves the storage and instantaneous release of energy. Reasonable energy management is crucial to ensure the performance of the laser generator. Laser generators usually rely on gain media (such as optical fibers, solid crystals, or gases) to store energy and release high-energy lasers when pulses are triggered. This process requires precise control to ensure that each pulse releases consistent energy, thereby ensuring processing consistency.

In high-energy pulsed laser systems, Q-switching or mode-locking techniques are usually used to adjust the energy release method. For example, Q-switching lasers can generate high-energy nanosecond pulses, while mode-locking lasers can generate ultra-short femtosecond pulses. The reasonable selection of energy storage and release methods can improve the stability of the laser generator and meet the needs of different applications.

Jakość wiązki

Beam quality is one of the key indicators to measure laser processing performance, which determines the focusing ability and processing accuracy of the laser beam. A high-quality laser beam has a good beam mode (such as TEM00 mode), which can be focused to a smaller spot size and achieve higher processing accuracy.

In pulsed laser systems, beam quality is affected by multiple factors, including optical system design, uniformity of gain medium, and stability of cavity. By optimizing the structure of the laser resonant cavity, using high-quality optical components, and precisely adjusting optical alignment, beam quality can be improved, thereby improving processing results. For example, in precision micromachining or semiconductor manufacturing, optimizing beam quality can ensure the accuracy of laser cutting and drilling and reduce defect rates.

System chłodzenia

Since pulsed laser generators generate a lot of heat during operation, a good cooling system is essential to maintain the stability of the laser generator and extend its service life. The cooling methods of laser generators mainly include air cooling, water cooling, or thermoelectric cooling (TEC).

For low-power pulsed laser generators, air cooling systems are usually effective enough, while high-power pulsed laser generators require water cooling systems to ensure stable heat dissipation. For example, in high-power laser cutting and welding applications, water cooling systems can prevent the laser generator from overheating, avoiding performance degradation or damage. In addition, intelligent temperature monitoring systems are also widely used in pulsed laser generators to automatically adjust the cooling power or stop operation when the temperature exceeds the safe range, thereby improving the safety and reliability of the equipment.

The design of a pulsed laser generator involves several key technical considerations, including the optimization of pulse duration and repetition rate, the control of energy storage and release, the improvement of beam quality, and the management of the cooling system. Reasonable optimization of these technical parameters can not only improve the processing accuracy and efficiency of the laser generator but also ensure its stability and reliability in long-term use. With the continuous development of laser technology, the design of pulsed lasers will be more precise in the future, bringing broader application prospects to industrial manufacturing, medical treatment, scientific research, and other fields.

Application of pulsed laser

Pulse lasers are widely used in many industries due to their high peak power, short pulse duration, and precise energy control. Compared with continuous wave (CW) lasers, pulse lasers can release a large amount of energy in a very short time, thereby reducing thermal effects and improving processing accuracy, and are suitable for a series of scenarios with extremely high requirements for energy control. The following are the main applications of pulse lasers in five major fields.

Industrial manufacturing

In modern industrial manufacturing, pulsed lasers are widely used in applications such as micromachining, welding, drilling, cutting, and material surface treatment. Short pulse lasers can precisely remove materials without causing excessive thermal damage, making them particularly suitable for precision machining industries. For example:

- Laser cutting and drilling: Pulsed lasers can efficiently cut hard materials such as metals, ceramics, and glass and drill micro-holes in electronic components, semiconductor wafers, and precision instruments.

- Laser welding: Pulsed laser welding has the characteristics of high strength and low heat input and is widely used in the automotive, aerospace, and electronics industries to ensure high-quality welding results.

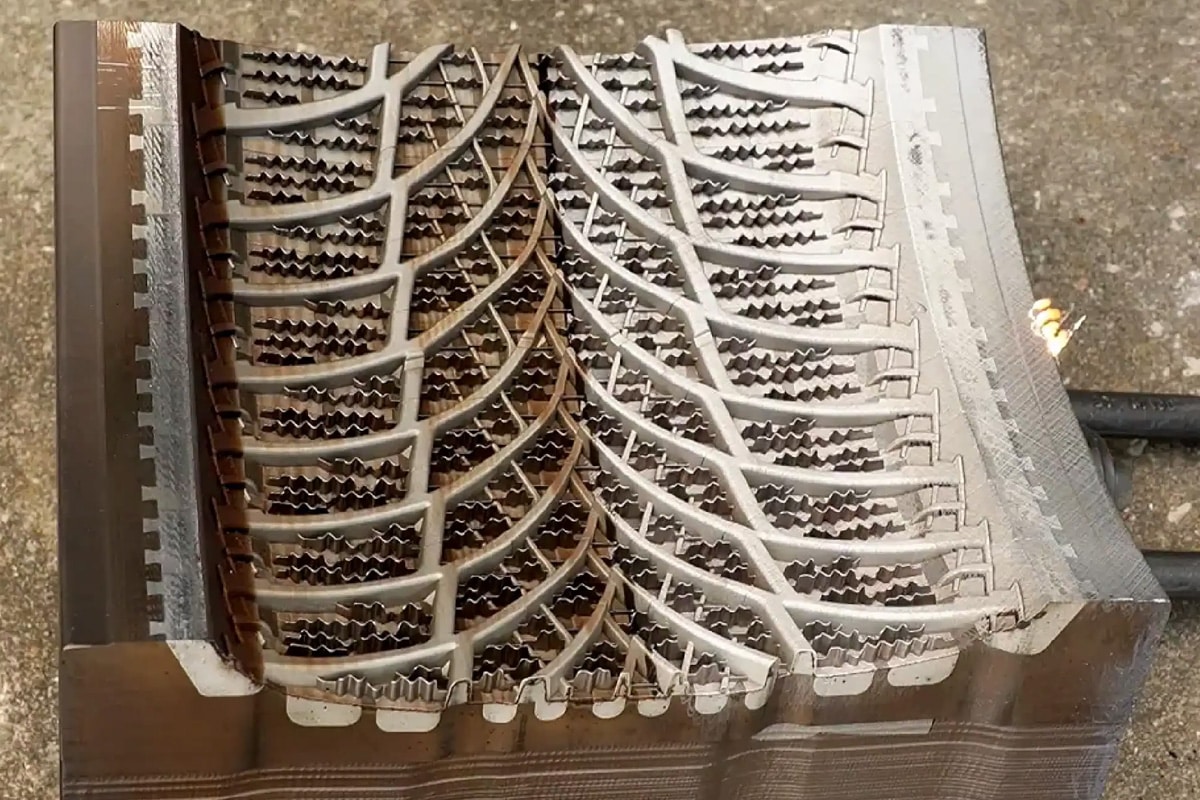

- Laser surface treatment: Pulsed lasers can be used to remove oxide layers, coatings, or rust and improve the durability and corrosion resistance of materials, such as in the aerospace field for cleaning and repairing engine parts.

Medical applications

The application of pulsed laser in medicine covers surgery, treatment and diagnosis, and can provide high-precision, non-contact medical intervention solutions. For example:

- Ophthalmic surgery: Femtosecond lasers are widely used in LASIK myopia correction surgery, which can accurately cut corneal tissue in a very short time, ensuring the safety and accuracy of the surgery.

- Skin disease treatment: Pulsed lasers can be used to remove pigmented lesions (such as freckles, moles and tattoos), as well as cosmetic medical applications such as skin rejuvenation, wrinkle removal and vascular treatment.

- Dental applications: Pulsed lasers are non-invasive and highly effective in tooth restoration, root canal treatment, and plaque removal.

Scientific research

Pulsed lasers play an important role in scientific research because they can provide ultra-high energy density and ultra-fast time resolution. For example:

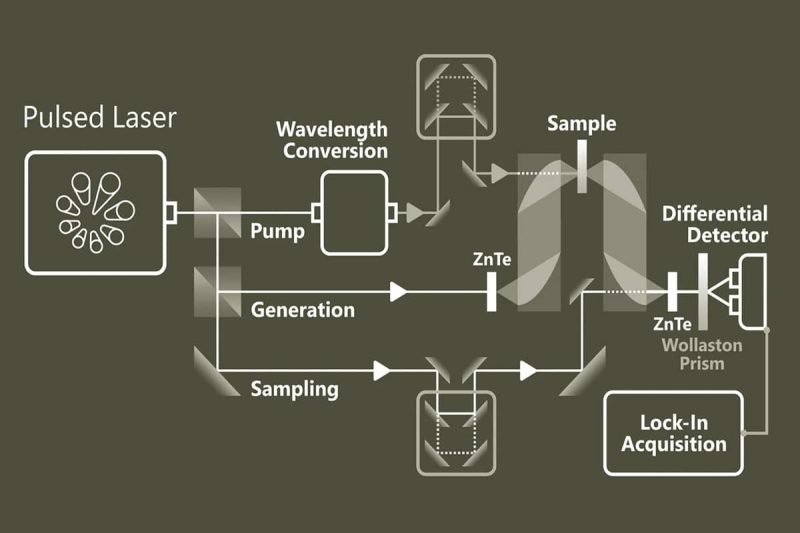

- Ultrafast laser spectroscopy is used to detect and study physical and chemical changes in matter in extremely short periods, such as electron transitions and molecular vibrations.

- Plasma physics: Pulsed lasers can produce high-energy plasma, providing an important experimental platform for fusion energy research.

- Particle acceleration: High-power pulsed lasers can be used in laser plasma accelerators, providing a new acceleration method for high-energy physics research and medical imaging.

Lotnictwa i Obrony

In the aerospace and defense fields, pulsed lasers are used in military weapons, optical sensing, and remote sensing detection. For example:

- Laser ranging and target identification: Pulsed laser ranging (LIDAR) technology is used for navigation, target tracking, and military reconnaissance and can provide high-precision terrain modeling and target identification capabilities.

- Laser weapons: High-power pulsed lasers can be used to destroy drones, missiles or other threatening targets, playing a key role in modern defense systems.

- Aerospace applications: Pulsed laser technology is used in satellite communications, space debris cleanup and deep space exploration missions to improve the accuracy and safety of space missions.

Communications and information technology

In optical communications and information technology, pulsed lasers are used for data transmission, optical storage, and photonic computing. For example:

- Fiber optic communication: Pulsed lasers can modulate signals at extremely high speeds to achieve large-capacity data transmission, and are one of the core technologies of modern Internet and 5G communications.

- Ultrafast optical storage: Pulsed lasers are used in high-density information storage technologies such as optical disk storage and holographic storage to increase the capacity and speed of data storage.

- Quantum communication: Pulsed lasers can be used for quantum key distribution (QKD), providing ultra-secure encrypted communications and ensuring the security of information transmission.

With their high peak power, short pulse time, and precise control capability, pulsed lasers have shown broad application prospects in industrial manufacturing, medical treatment, scientific research, aerospace, and communications. With the continuous advancement of technology, the application scope of pulsed lasers will be further expanded, providing stronger support for the development of intelligent manufacturing, medical innovation, national defense security, and information technology.

Challenges and limitations

Although pulsed laser technology has shown excellent performance and broad application prospects in many fields, such as industry, medicine, and scientific research, it still faces many challenges and limitations in practical applications. These include high equipment costs, high system complexity, limited material adaptability, and safety hazards. A deep understanding of these limitations is crucial to optimizing pulsed laser technology, lowering the threshold for use, and improving application effects.

Koszt

The development, manufacturing and operation costs of pulsed laser systems are high, which is mainly reflected in the following aspects:

- Expensive equipment: Pulse laser generators, especially ultrashort pulse (picosecond, femtosecond) laser generators, usually use advanced optical components, high-end pump sources, and precision control systems, so the overall price is much higher than that of continuous wave (CW) laser generators.

- High maintenance cost: Pulse laser systems require precise optical path alignment and stable environmental conditions. Equipment cooling, the replacement of optical components, and system debugging will increase long-term operating costs.

- High operating energy consumption: High-power pulse laser generators often require efficient cooling systems, which further increases energy consumption, making it necessary to consider cost control in large-scale industrial applications.

Złożoność

The precision of pulsed laser determines the complexity of its system design, which is specifically manifested in:

- High system integration difficulty: Pulse laser generators require precise control of pulse width, repetition rate and energy output, and also involve multiple engineering fields such as optics, electronics and thermal management, which increases the difficulty of R&D and manufacturing.

- High operator requirements: The commissioning and maintenance of pulse laser systems require professional operation, and users need to receive special training to fully utilize their high precision and high efficiency.

- Strict environmental requirements: Some ultrafast pulse laser generators are sensitive to ambient temperature, humidity, and vibration and may require special laboratories or production environments to ensure their performance stability.

Ograniczenia materialne

Although pulsed lasers can interact with a variety of materials, there are still material adaptability issues in certain specific application scenarios:

- Some materials have low absorption rates. Different materials have different absorption rates for lasers of specific wavelengths. Some transparent or highly reflective materials may have difficulty absorbing pulsed laser energy efficiently, thus affecting processing efficiency.

- The heat-affected zone still needs to be controlled: Although pulsed lasers have a smaller heat-affected zone than continuous-wave lasers, under certain high-pulse energy conditions, microscopic damage or structural changes may still occur to the material, affecting the final processing quality.

- Changes in material surface properties: Some materials may undergo phase changes or chemical reactions under the action of pulsed lasers, such as metal oxidation or the formation of microcracks on the glass surface, which may affect the final application effect.

Safety issues

The high energy density and ultra-short pulse characteristics of pulsed lasers require special attention in their safe use:

- Hazards to the human body: High-power pulsed lasers may cause serious damage to the eyes and skin. Even short-term exposure may cause irreversible damage. Therefore, special laser protection measures must be equipped during operation, such as goggles, shielding devices, etc.

- Electromagnetic interference problems: Some ultrafast laser systems may generate electromagnetic interference during operation, affecting surrounding electronic equipment and precision instruments, especially in medical and scientific research environments.

- Environmental safety hazards: Pulsed laser cleaning and processing may produce particles, aerosols, or plasma. If these byproducts are not properly handled, they may affect the safety of the working environment and even pose potential risks to human health.

Although pulsed laser technology has many advantages, its high cost, system complexity, material adaptability limitations, and safety risks are still key issues that need to be overcome in the application process. With the continuous advancement of technology, in the future, it may be possible to further promote the application of pulsed laser in a wider range of fields by reducing equipment manufacturing costs, optimizing system integration, improving material adaptability and strengthening safety protection measures, making it truly an important tool for modern industry, medical and scientific and technological innovation.

Podsumować

Pulse lasers are widely used in industry, medicine, scientific research, aerospace and communications due to their high peak power, short pulse duration and precision control capabilities. Although there are still challenges such as high cost and complex systems, with technological advances, pulse lasers will demonstrate their unique advantages in more fields. For companies, mastering pulse laser technology and optimizing its application will help gain a competitive advantage in the high-end manufacturing and precision machining markets.

Laser AccTek provides high-quality pulse laser solutions to help companies improve processing accuracy and production efficiency. If you want to learn more, please Skontaktuj się z nami!

Informacje kontaktowe

- [email protected]

- [email protected]

- +86-19963414011

- Nr 3 Strefa A, strefa przemysłowa Lunzhen, miasto Yucheng, prowincja Shandong.

Uzyskaj rozwiązania laserowe