Reliability And Life Management Of Laser Welding Machines

In modern manufacturing, laser welding technology is favored for its high precision, high efficiency, and multi-material applicability. As a key piece of equipment, the laser welding machine plays an important role in the production line. However, as production demands increase and competition intensifies, the reliability and life management of laser welding machines become particularly important.

The overall reliability and durability of a laser welding machine are important indicators in evaluating its performance and value. However, to ensure the reliability of laser welding machines, management and control need to be carried out from many aspects. To extend the service life of the laser welding machine, this article will elaborate on many aspects, including evaluating the overall reliability and durability of the laser welding machine, methods to effectively extend the service life of the laser welding machine, etc. Provide readers with a comprehensive guide to the reliability and life management of laser welding machines.

Table of Contents

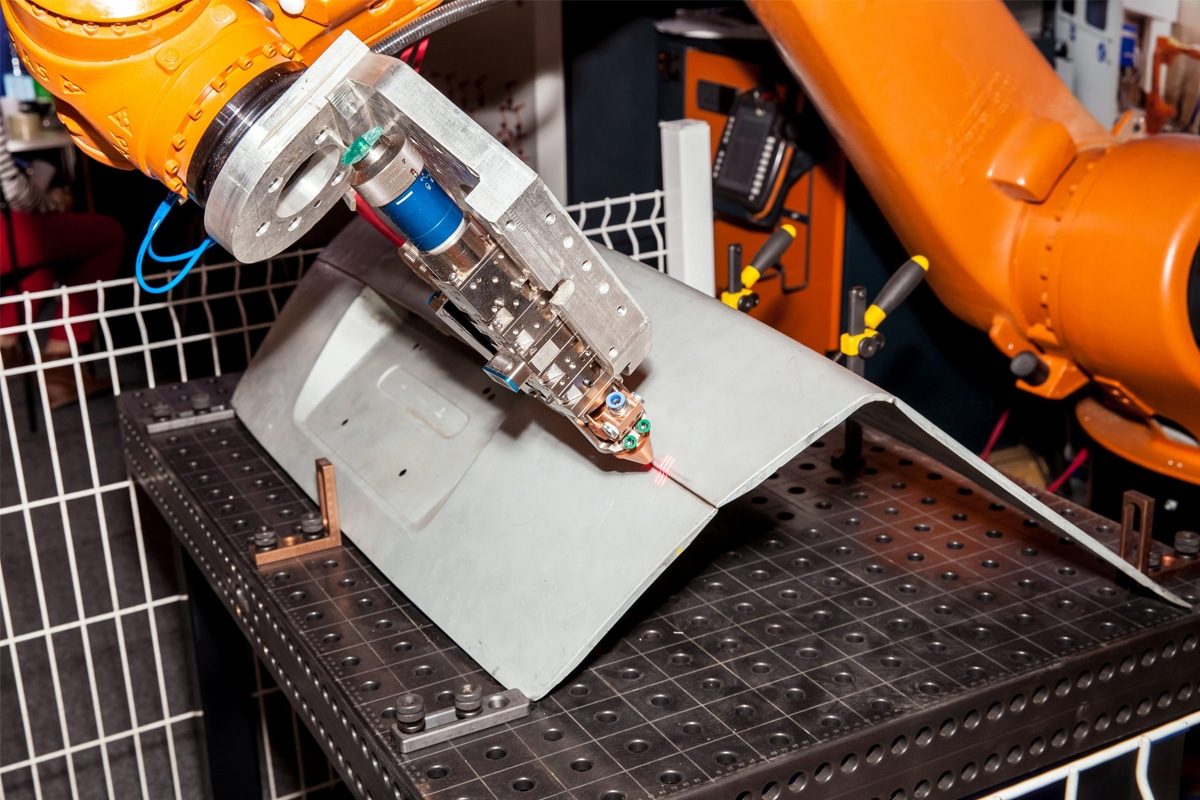

Working Principle Of Laser Welding Machine

The laser welding machine is a high-precision welding equipment that uses a laser beam to melt and join workpieces. Its working principle is based on the energy transfer and thermal effect of the laser

answer. The following is a brief description of the working principle of laser welding machine:

- Laser generator: The laser welding machine generates a high-energy laser beam through the laser generator. Laser sources usually use gas laser generators, solid laser generators, or semiconductor laser generators.

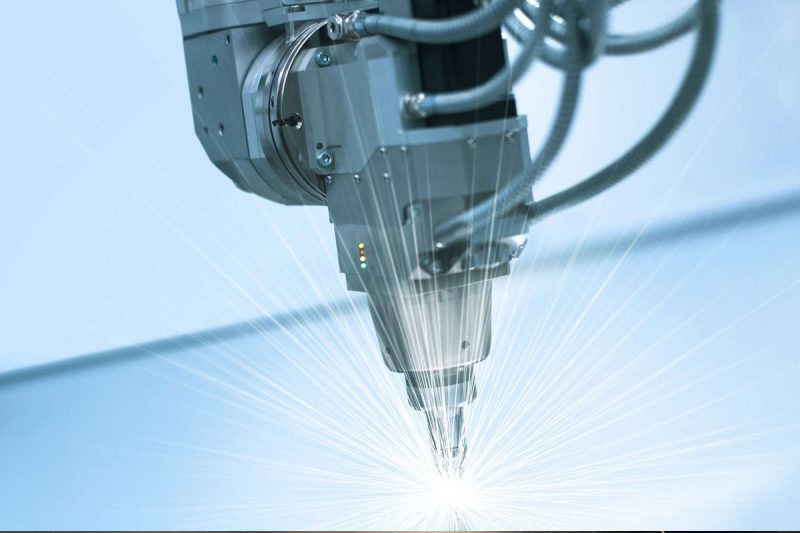

- Focusing system: The laser beam is focused by the focusing system to concentrate its energy density on a very small focus. Focusing systems typically include optical components such as lenses and convex lenses that are used to adjust and focus the laser beam.

- Workpiece surface irradiation: The focused laser beam is irradiated onto the workpiece surface. When the laser beam comes into contact with the surface of the workpiece, its energy is converted into heat energy, causing the surface of the workpiece to be locally heated above the melting point.

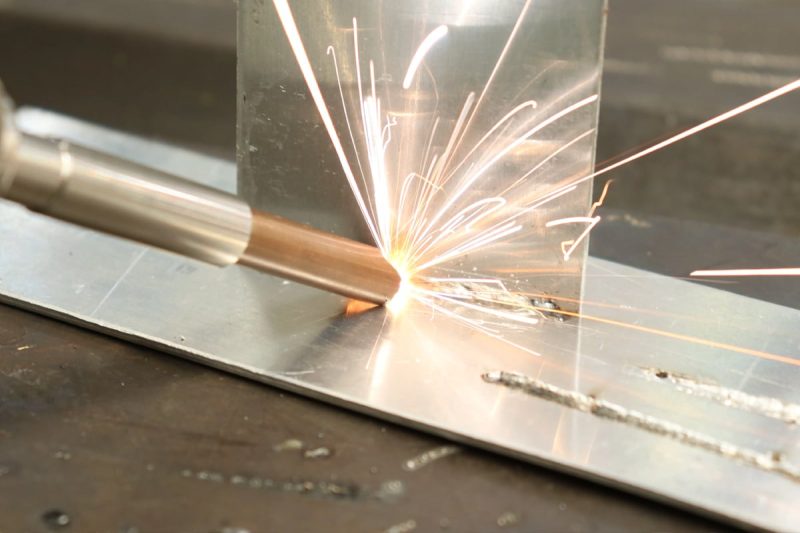

- Melting and joining: The laser beam forms a molten pool on the surface of the workpiece, and the material is instantly melted through the action of high energy density. When the laser beam moves, the molten pool moves with it to achieve welding of the workpiece. During the welding process, parameters such as the power, speed, and focus position of the laser beam can be controlled to achieve precise control of the weld.

- Cooling: After welding is completed, the molten pool quickly cools and solidifies to form a strong welded joint. Cooling of the welding area is usually required to ensure the quality and stability of the weld.

In general, laser welding machines utilize a high concentration of laser energy and thermal effects to achieve high-precision welding of workpieces. Its working principle is simple and efficient, and it is suitable for applications that require high welding quality and precision.

Overall Reliability Evaluation Of Laser Welding Machine

As a high-precision welding equipment, laser welding machine plays a vital role in modern manufacturing. Its reliability directly affects the stability and efficiency of the production line, so it is crucial to evaluate its overall reliability. The following is an evaluation of the overall reliability of the laser welding machine, described in points:

Design Quality

Design quality is one of the key factors affecting the reliability of laser welding machines. High-quality design can reduce failure rates and improve machine stability and performance. Evaluating the design quality of a laser welding machine requires consideration of factors such as structural design, material selection, and processing technology. Generally speaking, laser welding machines manufactured with advanced design technology and high-quality materials have higher reliability.

Parts Quality

The quality of laser welding machine parts directly affects the reliability of the overall equipment. High-quality parts can improve the stability and life of the machine and reduce the failure rate. When evaluating the reliability of a laser welding machine, a detailed quality assessment of its key components such as laser generators, optical components, control systems, etc. is required to ensure that they meet standards and have good performance.

Performance Stability

The performance stability of a laser welding machine during long-term operation is one of the important indicators of its reliability. Evaluating the performance stability of a laser welding machine requires considering its performance under different working conditions, including temperature changes, workload, continuous operation time, and other factors. Stable performance can ensure the consistency and stability of welding quality and reduce the failure rate.

Maintenance

Regular maintenance is the key to ensuring the long-term and stable operation of the laser welding machine. Timely cleaning, lubrication, and replacement of wearing parts can reduce machine wear and damage and extend the service life of the equipment. When evaluating the reliability of a laser welding machine, it is necessary to consider its maintenance design and support, including easy-to-maintain structural design, completeness of maintenance manuals, and other factors.

Fault Diagnosis And Repair Capabilities

Laser welding machines will inevitably malfunction during work, so their fault diagnosis and repair capabilities are also important indicators for evaluating their reliability. The equipment is equipped with a complete fault diagnosis system and a professional technical support team, which can detect and solve problems in time, reduce the impact of faults on production, and improve the reliability of the equipment.

To sum up, the evaluation of the overall reliability of a laser welding machine involves many aspects such as design quality, parts quality, performance stability, maintenance, and fault diagnosis and repair capabilities. Only when these aspects are fully considered and supported can laser welding machines be highly reliable and play an important role in modern manufacturing.

Overall Durability Evaluation Of Laser Welding Machine

The durability of the laser welding machine directly affects the stability and cost-effectiveness of the production line. Evaluation of its overall durability is a key factor in meeting the manufacturing industry’s requirements for equipment stability and reliability. The following is an evaluation of the overall durability of the laser welding machine, described in points:

Material Quality

The durability of a laser welding machine is first limited by the quality of the materials it uses. Durable laser welding machines are usually made of high-strength, wear-resistant, and corrosion-resistant materials to ensure that they are not prone to damage or aging during long-term work. When evaluating the durability of a laser welding machine, you need to consider the materials used in its various components and structures, and whether its durability meets design requirements.

Structural Design

Structural design is one of the important factors affecting the durability of laser welding machines. Reasonable structural design can improve the stability and vibration resistance of the equipment and reduce damage and fatigue caused by vibration. When evaluating the structural design of a laser welding machine, factors such as its rigidity, stability, and connection methods need to be considered to ensure that it can maintain good performance and stability during long-term work.

Quality Of Workmanship

The process quality of the laser welding machine directly affects its durability. Good process quality can ensure welding quality and strength of welded joints, and reduce fatigue and damage in the welding area. When evaluating the process quality of a laser welding machine, it is necessary to consider the setting of its welding parameters, the control of the welding process, and the detection of welded joints to ensure that its welding quality meets standard requirements.

Environmental Adaptability

Laser welding machines may face various challenges in different working environments, such as high temperatures, high humidity, corrosive media, etc. When evaluating the durability of a laser welding machine, it is necessary to consider its adaptability in different working environments, including design and measures for dustproof, waterproof, corrosion resistance, etc., to ensure that it can work stably and reliably in various harsh environments.

Maintenance

Regular maintenance is the key to ensuring the long-term and stable operation of the laser welding machine. Regular cleaning, lubrication, and replacement of wearing parts can reduce machine wear and aging and extend the service life of the equipment. When evaluating the durability of a laser welding machine, it is necessary to consider its maintenance design and support, including factors such as easy-to-maintain structural design and complete maintenance manuals.

Therefore, the evaluation of the overall durability of a laser welding machine involves many aspects such as material quality, structural design, process quality, environmental adaptability, and maintenance. Only by fully considering these aspects can the laser welding machine have high durability and operate stably for a long time.

Methods To Extend The Service Life Of Laser Welding Machines

Methods to extend the service life of laser welding machines can start from many aspects, including the following aspects:

Regular maintenance

Regular maintenance is the key to extending the service life of laser welding machines. Regular cleaning of equipment surfaces, lubrication of moving parts, and replacement of wearing parts can reduce machine wear and damage and keep the equipment in good condition. Establish maintenance records and perform maintenance according to prescribed cycles to ensure that every detail is paid full attention to.

Proper Use Of Equipment

Reasonable use of laser welding machines is also one of the important ways to extend their service life. Avoiding overload operation, long-term continuous work and frequent starts and stops can reduce machine wear and damage. In addition, following operating procedures and using equipment correctly can also effectively extend the life of the machine.

Repair Faults Promptly

Finding and solving problems in time is the key to ensuring the long-term stable operation of the laser welding machine. Once an abnormality is discovered in the machine, it should be stopped immediately for inspection and repaired in time. Don’t wait until the problem is serious before taking measures to avoid causing greater losses. Establishing a timely feedback mechanism to promptly deal with problems that arise during equipment operation can effectively extend the service life of the equipment.

Update Devices Regularly

With the development of science and technology, the technology of laser welding machines is also constantly updated. Regularly updating equipment and adopting new technologies and equipment can not only improve production efficiency and product quality but also extend the service life of the machine. Tracking the latest technological trends in the industry and updating equipment promptly is one of the important means to maintain the competitiveness of an enterprise.

Training Operators

Qualified operators are crucial to the normal operation and maintenance of equipment. Regular training of operators to improve their skills in equipment operation and maintenance can effectively extend the service life of the equipment. Operators should have good operating habits and maintenance awareness, and operate in strict accordance with operating procedures to ensure the safe and stable operation of the equipment.

Therefore, only by taking the above measures to extend the service life of laser welding machines and considering these factors can we effectively extend the service life of the equipment, improve production efficiency, and reduce costs.

Summarize

To sum up, the reliability and life management of laser welding machines are not only the key to ensuring the stable operation of the production line and product quality but also an important guarantee for improving corporate competitiveness and achieving sustainable development. Only by fully paying attention to and strengthening the reliability and life management of laser welding machines can we maximize production efficiency and provide strong support for the development of enterprises.

Therefore, attention to and management of the service life of laser welding machines will play an increasingly important role in the manufacturing industry. If you are looking for a reliable way to join metals quickly and accurately, please feel free to contact AccTek Laser. We will answer any questions you have or provide professional advice on laser welding machine maintenance.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions