Working Principle Of CO2 Laser Cutting Machine

Before we delve into the feasibility of integrating CO2 laser cutting machines with automation, we need to first understand the working principle of CO2 laser cutting machines. A CO2 laser cutting machine is a commonly used industrial processing equipment that uses a CO2 laser beam to melt and cut metal materials with high energy. Its working principle mainly includes the following steps:

- Laser emission: CO2 laser cutting machine uses CO2 gas as the laser medium to excite CO2 molecules through electrons, causing them to emit laser beams.

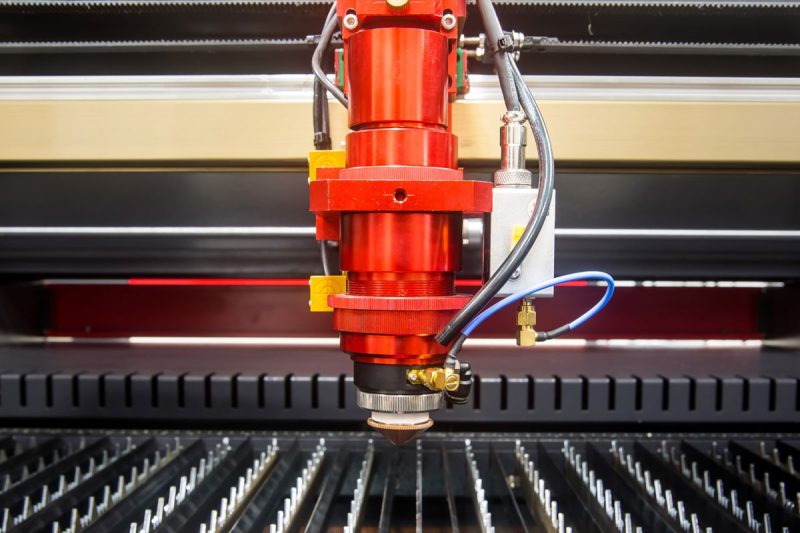

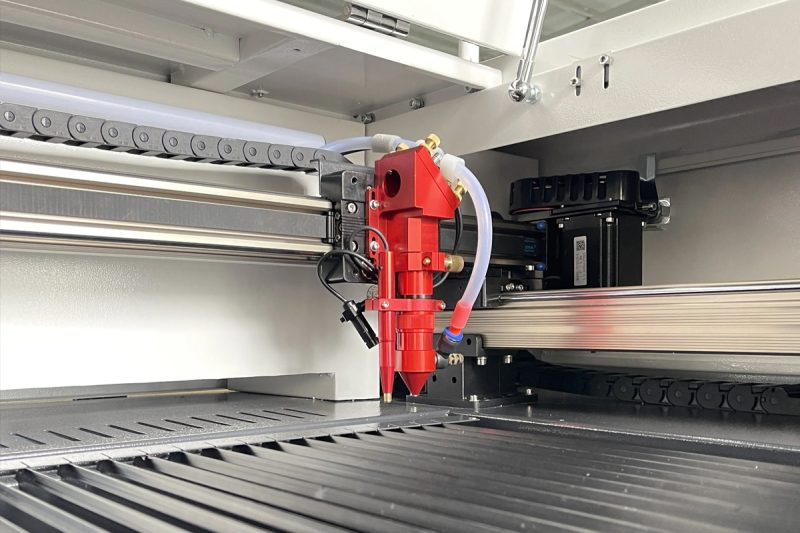

- Beam focusing: The laser beam is focused through optical devices, such as lenses or mirrors, to focus the beam on a very small focus.

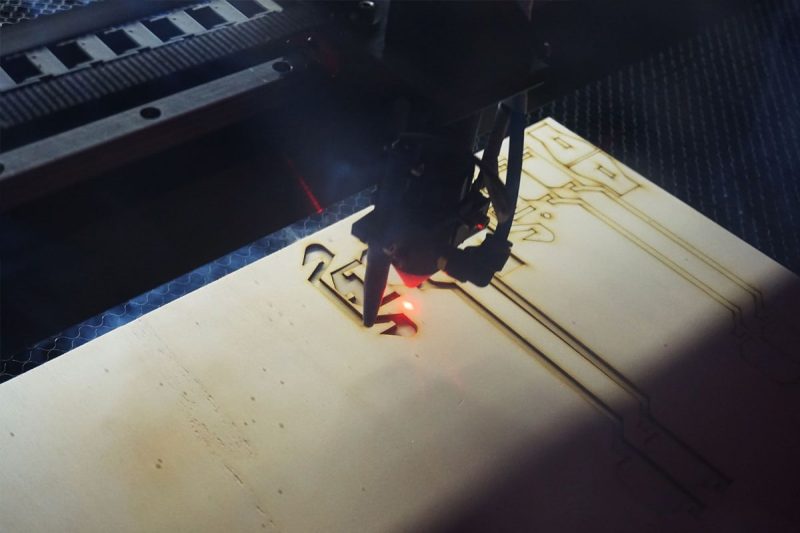

- Melting and cutting: The focused laser beam has a high energy density. When it hits the metal surface, it will quickly heat and melt the metal to form a molten pool. At the same time, the laser beam will also penetrate the metal surface and cut the metal material into the required shape and size.

- Gas assist: During the cutting process, inert gases such as oxygen and nitrogen are usually used as auxiliary gases to help cool the cutting area and evaporate the molten metal to improve cutting quality and speed.

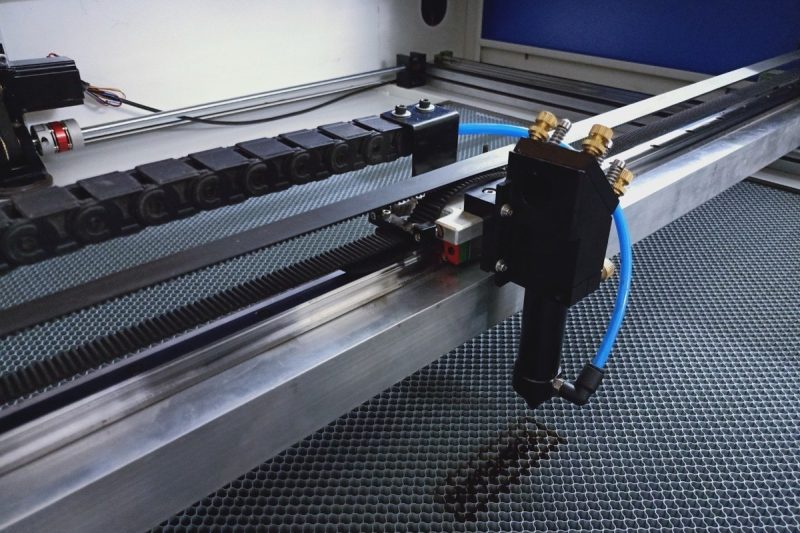

- Control system: The CO2 laser cutting machine is equipped with an advanced numerical control system, which can accurately control the position, power, and speed of the laser beam to achieve complex cutting paths and graphics.

The Importance Of Automation Systems In Industrial Production

Automation systems play a vital role in industrial production, and their importance is reflected in the following aspects:

- Improve production efficiency: Automation systems can automatically perform tedious and repetitive production tasks without being restricted by working hours and fatigue, thus greatly improving production efficiency.

- Reduce production costs: Automation systems can reduce manual operations and labor costs, reducing human input in the production process. In addition, automation can reduce scrap rates and energy consumption, thereby lowering production costs.

- Improve product quality: The automation system can accurately control various parameters in the production process, reduce the impact of human factors on product quality, and ensure product consistency and quality stability.

- Enhance production flexibility: The automation system has good programmability and flexibility, and can quickly adjust the production process and output according to production needs, improving the enterprise’s adaptability and flexibility.

- Improve safety and reliability: Automation systems can replace manual work in dangerous, high-temperature, high-pressure, and other tasks, reducing the risk of workers being exposed to dangerous environments and improving work safety.

Feasibility Of CO2 Laser Cutting Machine Integration In Automation Systems

Automation Control

Intelligent Monitoring

Automation Control Interface

Programmability And Flexibility

Enhance Production Efficiency

Implementation Steps For Integrating CO2 Laser Cutting Machine With Automation System

Integrating a CO2 laser cutting machine with an automation system is a complex project that requires a series of implementation steps to ensure completion. The following are general guidelines for implementation steps:

- Determine integration goals and requirements: Before starting implementation, you first need to clarify the goals and requirements for integration. What is the goal of determining integration? What functions need to be integrated? And what is the expected effect after integration? The answers to these questions will help guide the subsequent implementation process.

- Evaluate the compatibility of the CO2 laser cutting machine and the automation system: Before choosing an automation system, you need to evaluate the compatibility of the CO2 laser cutting machine and the automation system. This includes assessing whether the hardware and software interfaces between the two are compatible and whether a customized integration solution is required.

- Select the appropriate automation system and integration solution: Select the appropriate automation system and integration solution based on the integration goals and requirements. This may involve selecting an automatic feeding system, automatic receiving system, automatic control software, etc. suitable for CO2 laser cutting machines.

- Design the integration solution: Designing the integration solution is one of the key steps in the implementation process. When designing an integration solution, you need to consider the details of the physical connection, data transmission, control logic, etc. between the CO2 laser cutting machine and the automation system, and develop a detailed integration plan.

- Implementing the integrated solution: Implementing the integrated solution is the process of putting the design solution into practice. When implementing the integration solution, it is necessary to proceed step by step according to the design plan, including installing hardware equipment, debugging software systems, programming control logic, etc.

- Test the integration effect: After the integration is completed, the integration effect needs to be tested and verified. This includes comprehensive testing of the functions, performance, stability, and other aspects of the integrated system to ensure that the integrated system can achieve the expected results.

- Adjustment and optimization: After testing is completed, further adjustment and optimization of the integrated system may be required to meet actual production needs. This may involve adjusting control parameters, optimizing production processes, etc.

- Training and technical support: Finally, operators need to be trained to become familiar with the operation and maintenance of the integrated system. At the same time, technical support is also required to ensure the continued and stable operation of the integrated system.

Application Case Of Integrating CO2 Laser Cutting Machine With Automation System

The application case of integrating a CO2 laser cutting machine with an automation system is an important practical direction in the field of industrial automation. Here are some typical application cases:

- Automobile Manufacturing Industry: The automobile manufacturing industry requires high precision and efficiency in the production of parts. CO2 laser cutting machines are integrated with automation systems to build automated cutting production lines for the production of various parts such as automobile bodies, seats, and doors.

- Metal Processing Industry: In the metal processing industry, CO2 laser cutting machines are integrated with automation systems to achieve automated cutting of various complex parts. For example, a CO2 laser cutting machine can be integrated with a robotic system to achieve automatic grabbing, positioning, and cutting of metal sheets.

- Electronic Equipment Manufacturing Industry: In the electronic equipment manufacturing industry, various electronic components need to be precision cut. CO2 laser cutting machines are integrated with automation systems to build automated cutting production lines for the production of electronic components such as metal casings, circuit boards, and other components for mobile phones, tablets, TVs, etc.

- Aerospace Manufacturing Industry: In the aerospace manufacturing industry, the processing requirements for complex parts such as aerospace engines and aircraft fuselages are extremely high. The CO2 laser cutting machine is integrated with the automation system and can automatically cut various complex curved surfaces.

Summarize

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.