The Influence of Auxiliary Gas Selection on Laser Cutting Process

In modern industrial manufacturing, laser cutting technology, due to its high precision, flexibility, and high efficiency, has become an indispensable production tool in a variety of industries, including metalworking, automotive, electronics, and aviation. Compared to traditional mechanical cutting, laser cutting not only achieves high-precision processing of complex patterns but also maintains consistent cutting quality on both thin and thick plates, significantly improving production efficiency and material utilization. With the advancement of industrial automation, high-performance laser cutting machines have become essential equipment for companies to enhance their competitiveness.

In addition to core parameters such as laser power, cutting speed, focal length, and spot diameter, the choice of assist gas also plays a crucial role in cutting results. The assist gas not only removes molten material and cutting debris, preventing slag buildup and clogging at the cut edge, but also influences the oxidation state of the material surface and the cut finish through chemical reactions or inert protection. For example, using oxygen in carbon steel cutting can increase cutting speed, while using nitrogen in stainless steel or aluminum cutting can prevent oxidation and produce smoother cut edges.

Appropriate gas selection not only improves cutting efficiency but also significantly reduces subsequent processing and deburring, thereby saving production costs and improving overall processing quality. At the same time, flexible adjustment of gas flow and pressure according to material type, thickness, and cutting precision requirements can further optimize cutting performance, ensuring that each processing meets the expected standards. This makes the rational configuration of auxiliary gas a key factor that cannot be ignored in the laser cutting process, and has a direct impact on the company’s production efficiency and product quality.

Table of Contents

Laser Cutting Basics

Laser cutting is a high-precision, high-efficiency, non-contact processing technology widely used in industries such as metalworking, electronics, automotive, and aviation. In addition to laser power and cutting speed, the selection and control of assist gas also play a key role in cutting quality, efficiency, and cut finish.

Laser Cutting Process Principle

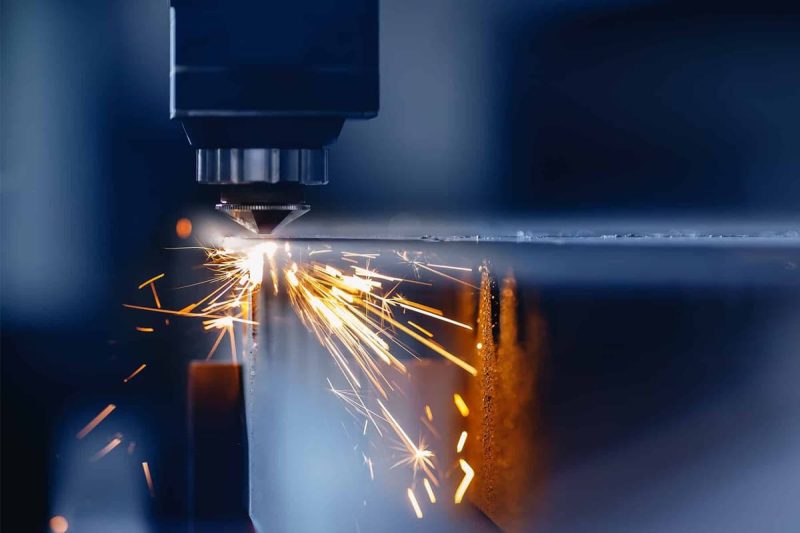

Laser cutting involves irradiating a high-energy laser beam onto the material surface, causing it to melt, vaporize, or evaporate in an extremely short period of time. An assist gas (such as oxygen, nitrogen, or air) then blows away the melt, creating a precise kerf.

- Non-contact processing: No mechanical contact is required, reducing material stress and deformation.

- High Precision: The small laser beam diameter enables the processing of complex patterns.

- High Efficiency: The processing speed is fast, making it suitable for cutting both thin and thick plates.

Common Laser Generator Types

Different materials and processing requirements correspond to different laser generator types:

- CO2laser generators: Suitable for materials such as wood, acrylic, they cut a wide range of thicknesses and are relatively cost-effective.

- Fiber laser generators: Suitable for stainless steel, aluminum alloys, and highly reflective metals, offering high cutting precision and low energy consumption.

- Crystal laser generators (such as Nd: YAG): Used for high-precision or micro-machining, suitable for cutting thin plates and electronic components.

Laser Cutting System Components

A complete laser cutting system generally includes:

- Laser source: Provides a high-energy beam, the core driving force of cutting.

- Optical transmission system: Accurately transmits the laser beam to the cutting head, ensuring a stable focus.

- Cutting head: Focuses the laser beam and controls the gas jet, directly impacting cut quality.

- Control system: Adjusts power, cutting speed, and pulse frequency to achieve high-precision processing.

- Assist gas system: Provides gas flow, pressure, and purity to optimize cutting efficiency and cut surface quality.

Key Parameters Affecting Cutting Performance

Cutting performance depends not only on laser power but also on the following factors:

- Laser power: Higher power increases cutting thickness and speed, but excessive power may lead to an expanded heat-affected zone.

- Cutting speed: A matching of speed and power determines kerf quality. Excessive speed can result in incomplete cuts or rough cuts. Focal Length and Spot Diameter: A shorter focal length and smaller spot size improve precision, but a too small focal length may increase the risk of scorching.

- Pulse Frequency: This affects cut continuity and surface finish, and is particularly important for thin plate or precision cutting.

- Assist Gas Pressure and Flow: Insufficient pressure may cause melt accumulation, while excessive flow may deflect the material, affecting cut quality.

Mastering the basics of laser cutting helps understand cutting principles, select an appropriate laser generator, and optimize cutting parameters. Proper assist gas configuration is crucial for improving cutting efficiency, ensuring cut quality, and minimizing post-processing. When designing a laser cutting process, comprehensively considering material properties, laser parameters, and gas type can maximize the performance of the laser cutting machine and provide a stable and efficient solution for industrial production.

The Role of Assist Gas in Laser Cutting

In the laser cutting process, assist gas is more than just a tool for “blowing away molten material.” It plays a crucial role in cutting quality, efficiency, and cut surface finish. Common assist gases include oxygen, nitrogen, and air. The choice of gas directly affects cutting speed, heat-affected zone, cut edge quality, and subsequent processing.

Improving Cutting Speed and Efficiency

Assist gas accelerates the discharge of molten material, making the cutting process smoother:

- Oxygen Cutting: This method uses an oxidation reaction to rapidly burn the material, increasing cutting speed and making it particularly suitable for carbon steel and thick plate metals.

- Nitrogen Cutting: Although there is no chemical reaction, nitrogen gas protects the cut surface from oxidation through a high-pressure jet, maintaining a stable cutting speed, though at a slightly lower speed than oxygen cutting.

- Air Cutting: This method offers lower cost, but due to the mixed gas content, its cutting speed and efficiency are relatively moderate, making it suitable for thin plate or non-critical materials.

Improving Cut Surface Finish

The assist gas has a direct impact on the flatness and finish of the cut edge:

- Nitrogen cutting of stainless steel and aluminum produces a smooth, oxide-free cut, reducing burrs.

- Oxygen cutting of carbon steel: While faster, it may produce a slightly oxidized edge, requiring post-processing.

- Gas flow and pressure: Too low a flow rate and pressure can result in melt retention and a rough cut; too high a flow rate can cause material deflection or a tapered kerf.

Reduces the heat-affected zone and material deformation

Assist gases provide cooling during the cutting process, helping to control the area of material exposed to heat:

- Inert gases (nitrogen, argon): effectively reduce the heat-affected zone and minimize material deformation, making them particularly suitable for high-precision or thin plate machining.

- Oxygen: While it increases cutting speed, the heat released by the chemical reaction may increase the localized heat-affected zone, requiring optimization of laser power and speed based on cutting parameters.

Reduces post-processing and machining

Choosing the right assist gas can reduce post-processing complexity and improve productivity:

- Smooth cuts reduce the need for deburring, saving labor and processing time.

- Nitrogen or high-purity air prevents oxidation and debris accumulation along the cut edge, improving consistent cut quality.

The Importance of Gas Purity and Stability

High-purity gas and stable gas flow are critical to achieving high-quality cutting.

- Gas impurities may cause a black oxide layer or burrs on the cut surface.

- Stable gas pressure and flow ensure cutting continuity, preventing melt backflow and uneven kerfs.

Assist gas plays multiple roles in the laser cutting process, including increasing cutting speed, improving cut surface finish, reducing heat-affected zones, and minimizing the need for subsequent processing. Different gases (oxygen, nitrogen, and air) each have their own advantages and applicable ranges. Properly selecting and optimizing gas flow, pressure, and purity based on material type, thickness, and cutting requirements can significantly improve laser cutting efficiency and processing quality, providing an efficient and stable solution for industrial production.

Factors Influencing Gas Selection

During the laser cutting process, the choice of assist gas is crucial to the cutting results. Different materials, thicknesses, and cutting requirements determine the most suitable gas, which in turn affects cutting speed, cut surface finish, heat-affected zone (HAZ), and post-processing efficiency. The following factors are key considerations when selecting a gas.

Material Characteristics

Different materials react significantly differently to assist gases.

- Carbon Steel: When cutting carbon steel, oxygen cutting can rapidly expel molten material through oxidation, increasing cutting speed, but may result in a slight oxide layer at the cut edge.

- Stainless Steel: Because stainless steel is susceptible to oxidation, inert gases such as nitrogen or argon are more suitable for cutting to ensure a smooth, oxidation-free cut.

- Aluminum and Aluminum Alloys: Due to their high reflectivity and thermal conductivity, using nitrogen can reduce oxidation and scorching while maintaining kerf precision.

- For non-metallic materials: such as acrylic, wood, or plastic, laser cutting primarily focuses on the gas’s ability to remove the molten material and the risk of combustion. Air or low-pressure nitrogen is generally sufficient.

Differences in material properties determine the choice of assist gas, which not only affects cutting quality but also directly impacts the cutting efficiency and production cost of the laser cutting machine.

Material Thickness and Composition

Material thickness is a key factor in determining the gas type and cutting parameters:

- For thick plate materials, such as thick carbon steel plates, oxygen is typically used for cutting. Oxygen reacts chemically with the metal, releasing additional heat, accelerating the discharge of the melt, and improving cutting efficiency.

- For thin plate materials or easily oxidized metals, such as thin stainless steel and aluminum, nitrogen is suitable for cutting to reduce kerf oxidation and ensure a smooth surface.

- Material Alloy Composition: Alloys with high chromium or aluminum content are more susceptible to kerf oxidation and melt adhesion during cutting, requiring the use of an inert gas shield.

Appropriately matching material thickness with gas type helps optimize laser cutting parameters, improve cutting efficiency, and minimize kerf burrs and distortion.

Cutting Speed and Precision Requirements

The speed and precision requirements of the cutting task directly influence the choice of assist gas:

- For high-speed cutting: For low-precision or thick plate cutting, oxygen can be used to accelerate the cutting process and improve laser cutting machine productivity. High-precision cutting: For machining precision parts or thin sheets, inert gases (nitrogen or argon) can reduce oxidation and improve cut flatness and finish.

- Controlling laser cutting parameters: Gas flow and pressure must be matched with power, focal length, and cutting speed to ensure consistent kerf size and edge quality.

Different cutting speeds and precision requirements dictate that gas selection must be optimized in conjunction with laser cutting machine parameters to achieve a balance between efficiency and quality.

Kerf Width and Edge Quality

The type and flow of auxiliary gas have a direct impact on kerf shape and edge quality:

- Kerf Taper: Excessive gas pressure or uneven flow can result in a tapered kerf, which is not conducive to high-precision assembly.

- Burr Generation: Using inert gas can effectively reduce burrs, reducing subsequent deburring and machining costs.

- Edge Finish: Nitrogen and high-purity air maintain smooth cuts, while oxygen cutting carbon steel may result in oxidized edges, requiring additional grinding.

By properly selecting gas type and adjusting flow and pressure, kerf geometry can be optimized, improving industrial processing consistency and efficiency.

Environmental and Safety Factors

In industrial production, environmental and safety considerations are also crucial when selecting gases:

- Cutting Fumes and Dust: Certain gases generate significant amounts of fumes, potentially impacting operational safety and equipment life.

- Flammability and Chemical Reactivity: Oxygen accelerates combustion, requiring strict control of the cutting environment and safety regulations.

- Gas Cost: High-purity nitrogen or argon are relatively expensive, requiring a balance between cost-effectiveness and cutting quality in large-scale production.

Safety, environmental protection, and cost-effectiveness are crucial factors in industrial laser cutting machine applications. A sound gas selection and usage strategy can mitigate risk while ensuring production stability.

Selecting the appropriate assist gas is a key component of laser cutting process optimization. The choice of oxygen, nitrogen, air, or other specialty gases is determined by factors such as material properties, thickness, cutting speed, and accuracy requirements, kerf geometry, and environmental safety. By strategically selecting the gas type, pressure, and flow rate, incorporating laser cutting machine parameters and production requirements, not only improves cutting efficiency and cut quality, but it also reduces post-processing costs, providing an efficient and stable solution for industrial production.

The Impact of Gas Selection on Laser Cutting Quality

In the laser cutting process, assist gas not only determines cutting speed but also directly impacts cut quality. Gas selection plays a key role in determining cut surface finish, kerf width, heat-affected zone (HAZ), and subsequent processing difficulty. The following analyzes the specific impact of gas on laser cutting quality from multiple perspectives.

Surface Finish and Edge Quality

The surface finish of the cut is a key indicator of laser cutting quality.

- Cutting stainless steel or aluminum with nitrogen effectively prevents oxidation, maintaining a bright and smooth cut, requiring virtually no post-processing.

- Cutting carbon steel with oxygen offers faster cutting speeds, but can result in a slight oxide layer on the edges, resulting in a darker surface color and requiring additional grinding or cleaning.

- Cutting with air offers a cut surface finish somewhere in between, making it suitable for thin sheet metal processing where surface quality requirements are less demanding.

Surface finish directly impacts component assembly accuracy and product appearance, so choosing the right gas can reduce rework and post-processing costs at the source.

Cutting Speed and Efficiency

The reaction mechanisms of different gases determine differences in cutting speed:

- Oxygen cutting: By reacting with the metal, it generates additional heat, accelerating melt discharge and increasing cutting speeds for thick carbon steel plates.

- Nitrogen cutting: Although cutting speeds are lower than oxygen, it maintains high-quality cuts and is suitable for precision machining with stringent edge requirements.

- Air cutting: Suitable for rapid processing of medium- and low-thickness materials, ensuring efficiency while reducing gas costs.

For high-volume manufacturers, finding a balance between laser cutting efficiency and cut quality is the key to optimizing gas selection.

Heat-Affected Zone and Deformation

The size of the heat-affected zone (HAZ) determines the material’s susceptibility to deformation.

- Inert gases (nitrogen, argon): They effectively reduce the range of heat conduction during cutting, minimizing the HAZ and preserving the material’s original properties.

- Oxygen cutting: The additional heat released may increase the HAZ, especially when cutting thin plates, leading to slight edge warping.

In industries such as aerospace and precision electronic components, minimizing the HAZ is crucial to ensuring part strength and stability.

Kerf Width and Taper

The pressure and purity of the assist gas affect the kerf width:

- High-pressure nitrogen cutting: produces a narrower kerf, maintaining verticality and consistency.

- Oxygen cutting: While cutting speed is high, the kerf is relatively wide and may exhibit a slight taper.

- Insufficient gas flow: prevents the melt from being discharged promptly, resulting in uneven kerfs and poor cutting accuracy.

Kerf width directly affects assembly clearance and material utilization, making it a key consideration for reducing production costs in the manufacturing industry.

Reducing Deburring and Post-Cutting Steps

The correct choice of assist gas can reduce subsequent processing steps:

- Nitrogen cutting: produces a smooth, oxide-free cut, significantly reducing deburring and polishing steps.

- Oxygen cutting of carbon steel: oxide layers and burrs easily form on the cut edges, requiring subsequent polishing.

- Air cutting: may produce slight burrs on the edges, but is an acceptable option for low-cost production.

Reducing deburring and post-processing steps not only improves production efficiency but also reduces labor and equipment investment, which is particularly important for large-scale production.

The choice of assist gas directly determines the quality of laser cutting. The proper use of oxygen, nitrogen, or air not only affects cutting speed and efficiency but also impacts surface finish, heat-affected zone size, kerf width, and subsequent processing costs. When developing a cutting plan, companies should consider material characteristics, thickness, and precision requirements to scientifically select the assist gas, flow rate, and pressure to achieve efficient, stable, and high-quality laser cutting results.

Comparative Analysis of Assist Gases

Common assist gases used in laser cutting include oxygen, nitrogen, compressed air, argon, and some specialty gases. Different gases have their own advantages and limitations in terms of cutting speed, cut quality, cost, and application scenarios. The following compares and analyzes several common gases.

Oxygen (O2)

Oxygen is the most widely used assist gas in carbon steel laser cutting.

- Cutting Speed: Oxygen undergoes a strong oxidation reaction with the metal, releasing additional heat, significantly improving the efficiency of thick plate cutting.

- Cut Quality: An oxide layer forms on the cut edge, resulting in a darker surface color. In some cases, additional grinding or deburring may be required.

- Application: Low-precision cutting of thick carbon steel and stainless steel plates.

- Disadvantages: The cut edge may reduce corrosion resistance, making it unsuitable for parts requiring high precision and a high finish.

Therefore, oxygen cutting is more suitable for applications that require high efficiency but less demanding cut surface finishes.

Nitrogen (N2)

Nitrogen is one of the most widely used inert gases in laser cutting machines and is particularly suitable for cutting high-quality materials such as stainless steel and aluminum.

- Cutting Speed: Cutting speed is lower than that of oxygen, but high-pressure nitrogen can maintain stable cutting.

- Cutting Quality: Cuts are smooth and free of oxide layers, requiring little to no post-processing.

- Applications: Materials requiring high edge quality, such as stainless steel, aluminum, and aluminum alloys, and copper.

- Disadvantages: High nitrogen consumption and high cost, especially when machining thick plates.

Nitrogen cutting is suitable for high-precision manufacturing industries such as automotive parts, aerospace, and medical devices.

Compressed Air

Air cutting is widely used for cutting medium to thin plates due to its low cost and readily available supply.

- Cutting Speed: Between that of oxygen and nitrogen, suitable for medium-speed machining.

- Cutting Quality: Cuts are generally smooth, with slight oxidation or burrs on the edges possible.

- Applications: Thin plate cutting of carbon steel, stainless steel, and aluminum, particularly in cost-sensitive industries. Advantages: Low cost, strong versatility, and suitable for small and medium-sized processing companies.

Although air cutting does not offer the same cut quality as nitrogen, its high cost-effectiveness makes it widely used in the mid- and low-end markets.

Argon (Ar)

Argon is an inert gas, often used for special materials or where high cut protection is required.

- Cutting speed: Lower than nitrogen and oxygen, but provides stable cut protection.

- Cut quality: The cut is free of oxide layers, with a smooth edge finish, preventing damage to the material’s chemical properties.

- Applications: Cutting titanium alloys, magnesium alloys, and other reactive metals.

- Disadvantages: High gas cost and low cutting efficiency, generally unsuitable for large-scale mass production.

Argon cutting is more commonly used for processing high-value-added materials, such as in aerospace and medical device manufacturing.

Other specialty gases

In addition to the common gases oxygen, nitrogen, air, and argon, some specialized processes utilize mixed or specialty gases.

- Mixed gases: For example, a mixture of nitrogen and argon can achieve both good cut finish and good cut protection.

- Helium (He): Used in a limited number of high-end applications, it offers excellent heat dissipation, but its cost is extremely high.

This type of gas is typically used in scientific research experiments or specialized processes and has yet to be widely adopted in industrial production.

Different gases have different performance advantages in the laser cutting process: Oxygen cuts quickly and efficiently, making it suitable for thick carbon steel plates. Nitrogen cuts with high quality and no oxidation, making it suitable for stainless steel and aluminum. Air cuts at a low cost and offers high versatility, making it suitable for processing medium and thin plates. Argon cuts with high protection, making it suitable for specialty metals and high-end manufacturing. When selecting an assist gas, companies should consider material characteristics, cutting thickness, precision requirements, and cost budget, and scientifically formulate laser cutting process parameters to achieve the optimal balance between cutting quality and production efficiency.

Gas Selection Optimization Strategies

In actual production, the optimal selection of assist gas directly determines the overall quality and efficiency of laser cutting. Due to the varying material types, thicknesses, and precision requirements, companies need to flexibly adjust their cutting strategies based on specific circumstances. The following are several common optimization strategies:

Choosing the right gas based on material type

- Carbon steel cutting: Oxygen is recommended, as it utilizes the heat generated by the oxidation reaction to improve cutting efficiency, especially for thick plate cutting.

- Stainless steel and aluminum cutting: Nitrogen is recommended to prevent oxidation and ensure a bright, smooth cut.

- Non-ferrous metals and special alloys: Argon or nitrogen provides excellent protection, preventing changes in the chemical properties of the cut.

By matching different materials with different gas types, cutting quality can be ensured at the source.

Considering material thickness and cutting speed

- Thick plate cutting: Oxygen significantly increases cutting speed, but requires enhanced surface cleaning in post-processing.

- Thin plate cutting: Nitrogen or air is more suitable, enabling controlled kerf width while maintaining a clean cut edge.

In production practice, the balance between thickness and cutting speed determines the optimal solution for efficiency and cost.

Optimizing Gas Pressure and Flow

The pressure and flow of auxiliary gas directly impact the slag removal and cooling effects of the cut:

- High-pressure nitrogen: Suitable for high-precision cutting, producing narrow, smooth kerfs.

- Low-pressure oxygen: Used for ordinary carbon steel processing, it ensures efficiency while reducing gas consumption.

Properly adjusting gas pressure can avoid excessive burrs and slag residue on the cut, thereby improving overall cutting quality.

Balancing Cutting Quality and Cost Control

In actual production, companies often need to strike a balance between cutting performance and cost.

- High-end applications: Industries such as aviation and medical devices prefer nitrogen or argon to ensure a free oxide layer on the cut.

- Mass manufacturing: Industries such as home appliances and sheet metal processing prefer air or oxygen cutting, making them more cost-effective options.

By optimizing process parameters and optimizing gas configuration, cost reduction and efficiency improvement can be achieved.

Consider Environmental and Safety Factors

Assist gas selection not only affects cutting quality but also impacts workshop environment and operational safety:

- When using oxygen, be mindful of fire risks.

- When using high-pressure nitrogen or air, ensure equipment safety and stability.

- Reducing cutting smoke and exhaust emissions complies with environmental requirements.

While pursuing efficiency, companies should also prioritize environmentally friendly production.

Optimizing gas selection is a comprehensive process that requires consideration of multiple factors, including material type, thickness, cutting speed, cost budget, and safety and environmental protection. By optimizing assist gas combinations and adjusting process parameters, not only can laser cutting quality be improved, but efficiency and cost can also be balanced, ultimately enhancing production competitiveness for companies.

Summary

Laser cutting, as a high-precision, high-efficiency processing method in modern manufacturing, has been widely used in various fields, including metalworking, automotive manufacturing, aerospace, and electronics. In addition to hardware factors such as laser power, cutting speed, and optical system, the selection and optimization of assist gases are also crucial factors in determining cutting results.

From oxygen, nitrogen, air, to argon, different gases have their own advantages and disadvantages in terms of cutting speed, cut surface finish, cost control, and environmental adaptability. Oxygen cutting is suitable for high-efficiency processing of thick plates, nitrogen cutting meets high-precision and high-quality requirements, air cutting combines low cost and flexibility, while argon and specialty gases demonstrate advantages in special alloys and high-end applications. In actual production, companies must scientifically select the appropriate assist gas and process parameters based on material properties, plate thickness, precision requirements, cutting efficiency, and cost budget.

At the same time, appropriate gas flow and pressure regulation not only improve kerf edge quality and reduce the heat-affected zone, but also reduce subsequent grinding and deburring processes, significantly improving production efficiency and product consistency. Especially in the current context of increasingly fierce competition in the manufacturing industry, optimizing laser cutting processes to reduce costs and increase efficiency has become a crucial path for companies to enhance their competitiveness.

In short, the scientific and optimized selection of assist gases not only impacts cutting quality and efficiency but is also a key factor in achieving efficient production, cost control, and sustainable development. In the future trend of intelligent manufacturing, manufacturers will be able to better meet market demands for high-quality processing and efficient production by leveraging advanced laser cutting equipment and optimized assist gas strategies.

Get a Laser Solution

In real-world production, different companies face vastly different cutting requirements: some require high-efficiency processing on thick carbon steel plates, others prioritize high-quality cutting of stainless steel and aluminum alloys, and still others focus on precision manufacturing of specialized materials. Regardless of evolving needs, scientific assistance in gas selection and laser cutting process optimization remains key to ensuring cutting quality and efficiency.

If you would like to learn more about laser cutting solutions tailored to your production needs, or require professional advice on equipment selection, process parameters, and assist gas application, please contact us. As a manufacturer deeply rooted in the laser processing field, AccTek Laser is committed to providing high-performance laser cutting equipment and comprehensive technical support to customers worldwide, helping you achieve more efficient, cost-effective, and high-quality production.

Whether you are in the metalworking, automotive, sheet metal, aerospace, or precision manufacturing industries, we can provide you with customized laser cutting solutions to help your business stand out from the competition.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions