What Factors Should Be Considered When Choosing a CO2 Laser Cutting Machine?

In the world of modern manufacturing and manufacturing, CO2 laser cutting machines have become indispensable tools, delivering unparalleled precision, versatility, and efficiency in numerous applications. Whether you run a small workshop, or a large manufacturing facility, or are a hobbyist crafting complex designs, choosing the right CO2 laser cutting machine is crucial to achieving the best results. However, with the market flooded with a plethora of options, each with its unique features and capabilities, choosing the right CO2 laser cutter is undoubtedly more beneficial in achieving the best results. This article explores key factors and other considerations that should be carefully considered when choosing a CO2 laser-cutting machine. By understanding these key aspects, businesses and individuals can make informed decisions that align with their specific requirements and goals, ultimately increasing productivity and driving the success of their efforts.

Table of Contents

Learn About CO2 Laser Cutting Machine

In modern manufacturing, CO2 laser cutting machines are among the tools of high precision, efficiency, and versatility. Understanding the complexity of this technology is beneficial in seeking to exploit its capabilities for a variety of applications.

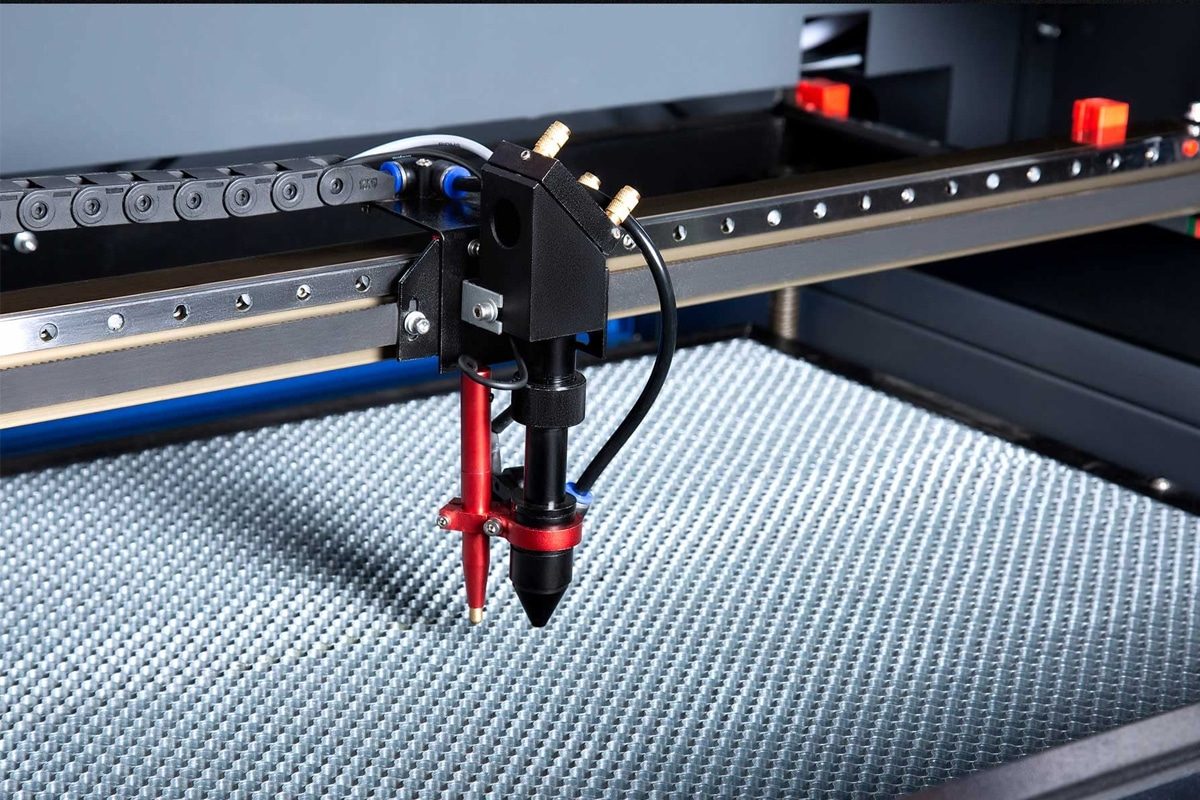

Basic Principles

The core concept of a CO2 laser cutting machine is to use a carbon dioxide laser generator to produce a high-power beam. This laser beam passes through a series of mirrors and lenses that ultimately focus its energy onto the material to be cut or engraved. The intense heat generated by the laser beam vaporizes or melts the material, creating precise cuts or marks. The wavelength of the CO2 laser generator (10.6 microns) is particularly suitable for cutting non-metallic materials such as wood, acrylics, plastics, fabrics, and various composite materials.

Application Industry

CO2 laser cutting machines are used in a variety of industries, including automotive, aerospace, electronics, signage, packaging, and textiles. In the automotive sector, CO2 laser generators are used for precision cutting of interior parts, gaskets, and composite materials. In the aerospace sector, they play an important role in manufacturing lightweight components with complex designs. In electronics, CO2 laser generators are used to cut and engrave circuit boards and housings. Additionally, CO2 laser cutting machines are widely used in the production of signage, packaging prototypes, and custom-designed textiles.

Development Trend

CO2 laser cutting technology has made significant advances over the years, resulting in improvements in speed, accuracy, and efficiency. A notable trend is the integration of automation and computer numerical control (CNC) systems, resulting in enhanced control and accuracy of cutting operations. Additionally, developments in laser source technology have led to the emergence of fiber optic and hybrid laser systems, providing increased power and versatility for a wider range of materials and thicknesses. Additionally, there is an increasing focus on environmentally friendly solutions, with manufacturers exploring ways to reduce energy consumption and emissions associated with the CO2 laser-cutting process.

By understanding the basic principles, development trends, and application directions of CO2 laser cutting technology, companies can use their capabilities to simplify production processes, improve product quality, and promote cross-industry innovation.

Key Factors to Consider

Choosing the right CO2 laser-cutting machine requires careful consideration of a variety of factors to ensure optimal performance, efficiency, and compatibility with specific manufacturing needs. From cutting speed and laser power to software compatibility and maintenance requirements, every aspect affects a machine’s suitability for its intended application. This paragraph aims to shed light on the key factors that should be considered when choosing a CO2 laser-cutting machine, enabling businesses and individuals to make an informed decision that is consistent with their requirements and goals.

Cutting Speed

The cutting speed of a CO2 laser cutting machine determines the speed at which it can process materials. Faster cutting speeds can significantly increase productivity, especially in high-volume manufacturing environments. Therefore, we need to strike a balance between speed and cutting quality. While higher speeds may speed up production, cutting too fast can also compromise the accuracy and quality of the finished product. Therefore, it is more beneficial to evaluate your production requirements by choosing a machine with a cutting speed that matches your desired balance of speed and quality.

Laser Power

Laser power plays an important role in determining the cutting capabilities of CO2 laser-cutting machines. Higher laser power allows the processing of thicker materials and faster cutting speeds. When evaluating laser power requirements, consider the type of material you will be working with and the depth of cut required. Choose a machine with enough power to meet your application needs while also focusing on cut quality. Additionally, higher laser powers may require more cooling systems and energy consumption, so consider these factors when choosing the appropriate power level for your machine.

Laser Source

The quality and type of laser source are key considerations when choosing a CO2 laser-cutting machine. Choose a reputable brand known for its durable, efficient laser sources to ensure reliable performance and minimal downtime. Different laser sources may offer different beam quality, stability, and lifetime, research and compare options to find the best laser source for your needs. Additionally, factors such as maintenance requirements and serviceability should be considered when selecting a laser source, as these factors can affect the long-term reliability and cost-effectiveness of the machine.

Cutting Area

The cutting area of the CO2 laser cutting machine determines the maximum size of the material that can be processed. Assess your production needs and material size to select a machine with the appropriate cutting area. Choose a machine with a cutting area that can accommodate your largest anticipated workpiece without sacrificing efficiency or flexibility in its work. Keep in mind that larger cutting areas may require a larger machine footprint and higher initial investment, so consider these factors when determining the best size for your application.

Accuracy and Precision

Accuracy and precision are among the advantages of CO2 laser cutting machines, especially for applications requiring complex designs and tight tolerances. Evaluate the machine’s positioning accuracy, repeatability, and motion control system to ensure precise and consistent cutting results. Look for features like linear encoders and servo motors that help improve accuracy and repeatability. Additionally, factors such as beam quality and stability must be considered, as these factors can also affect the overall accuracy of the cutting process.

Software Compatibility

Software compatibility can help a CO2 laser-cutting machine maximize its functionality. Make sure the machine supports industry-standard design software and file formats so it can integrate seamlessly into your existing workflow. Compatibility with CAD/CAM software enables an efficient design-to-production process, while an intuitive control interface simplifies operation and programming tasks. Evaluate your machine’s software capabilities and compatibility to ensure compatibility with your specific application requirements.

Maintenance and Support

Regular maintenance helps ensure the service life and optimal performance of your CO2 laser cutting machine. Prioritize machines with reliable technical support and readily available spare parts to minimize downtime and maximize productivity. When evaluating maintenance and support services, consider factors such as service agreements, training programs, and remote diagnostic capabilities. Additionally, ask about the manufacturer’s warranty coverage and service response times to ensure any issues that may arise are addressed promptly.

Security Features

Safety should be a top priority when operating a CO2 laser-cutting machine. Look for machines equipped with comprehensive safety features, including safety interlocks, enclosed work areas, and laser beam guards. These features help reduce the risk of accidents and ensure operators are protected during operations. Additionally, consider machines with additional safety features such as emergency stop buttons, door sensors, and exhaust systems to further enhance workplace safety.

Costs and Budgets

Consider initial investment cost, operating expenses, and long-term return on investment when evaluating a CO2 laser cutting machine. Consider additional costs such as consumables, maintenance, and training to determine the total cost of ownership. Assess your budget constraints and prioritize features and functionality that meet your specific needs and requirements. While upfront costs must be considered, the long-term value and benefits provided by the chosen machine must also be evaluated to ensure the investment is cost-effective.

User-Friendliness

User-friendly machines ensure smooth operation and maximize productivity. Look for features like intuitive controls, simple setup and maintenance procedures, and comprehensive training and support resources. Machines with clear safety features and ergonomic design further enhance the user experience, increasing operator satisfaction and efficiency. By prioritizing user-friendliness and technical specifications, businesses can choose a CO2 laser cutter that not only meets their performance requirements but also facilitates seamless integration into their workflow.

By carefully considering these key factors (accuracy and precision, software compatibility, maintenance and support, safety features, and cost and budget), you can ensure that the CO2 laser cutting machine you choose meets your specific requirements and delivers performance, reliability performance, and security to meet your application needs.

Other Things to Note

In addition to technical specifications and user-friendliness, there are several other key factors to consider when choosing a CO2 laser-cutting machine.

Brand Reputation

The reputation of a manufacturer or brand carries a lot of weight. Choosing a reputable brand ensures not only reliability but also quality and consistent performance. Dive into extensive research including customer reviews, testimonials, and industry reports to gain valuable insights into your brand’s reputation and track record.

Warranty and After-Sales Support

Before choosing a CO2 laser cutting machine, you need to evaluate the warranty coverage and after-sales support provided by the manufacturer. A comprehensive warranty not only gives you peace of mind but also protects your investment against unforeseen problems. In addition, responsive after-sales support ensures that any technical challenges encountered during operations are quickly resolved, minimizing downtime and maximizing productivity.

Future Expansions and Upgrades

It is crucial to consider the potential for future expansion and upgrades. Choose a CO2 laser cutting machine that is scalable and compatible with add-on accessories or modules to meet changing production needs. Ask about available upgrade options, such as increased laser power or advanced software features, to ensure your machine can adapt and grow with your business.

By combining these additional considerations with technical specifications and user-friendliness, businesses can make an informed decision when selecting a CO2 laser cutting machine that not only meets their current requirements but also complements their future expansion plans to maximize return on investment and ensure long-term success.

Summarize

Choosing a suitable CO2 laser-cutting machine is an important decision, and you need to consider various factors carefully. This article comprehensively discusses the key aspects that enterprises and individuals should evaluate when choosing CO2 laser-cutting machines. From the technical specifications such as cutting speed, laser power, and cutting area, to user-friendly and brand reputation, such as user-centric factors, each aspect is determining the machine’s applicability to specific applications. In addition, this article also emphasizes the importance of warranty, after-sales support, and the importance of future expansion and upgrade potential to ensure the seamless and efficient experience of the selected machine. Through deeply weighing these factors, companies can make wise decisions that meet their needs, goals, and long-term growth plans in the field of CO2 laser cutting technology.

Are you ready to harness the power of CO2 laser-cutting technology for your manufacturing and fabrication needs? Whether you’re seeking precision cutting for thin materials or tackling thicker substrates with ease, our team is here to provide tailored solutions to meet your requirements. Contact us today to discuss your laser-cutting needs and explore how our solutions can help you achieve your goals. Whether you have questions about maximum cutting thickness, material compatibility, or custom cutting requirements, our team is ready to provide expert guidance and assistance every step of the way.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions