What is a Laser Marking Machine?

How Does a Laser Marking Machine Work?

Key Components of a Laser Marking Machine

A laser marking machine’s efficiency, accuracy, and safety rely on several critical components:

- Laser Source: The laser source generates the laser beam with specific characteristics like wavelength and power. Different types of laser sources (fiber, CO2, UV, and green) are used depending on the material and application. For instance, fiber lasers excel with metals, while UV lasers are ideal for heat-sensitive materials.

- Beam Delivery System: The beam delivery system includes mirrors, lenses, and sometimes beam expanders. This system precisely directs the laser from the source to the material, ensuring minimal energy loss and high focus.

- Scanning System (Galvanometer Scanners): Galvanometer scanners, or “galvos,” are high-speed mirrors that control the direction of the laser beam. They rapidly steer the beam across the work surface according to the programmed design, allowing for quick, precise marking.

- Control Software: Control software enables users to design the markings, adjust laser parameters (such as speed and intensity), and manage the entire marking process. Advanced software options also support real-time adjustments, allowing for complex and intricate designs.

- Workpiece Handling System: This system is used to position and secure the material during marking, ensuring stability and accuracy. In industrial setups, it might include conveyors or robotic arms to automate handling for high-volume production.

- Cooling System: The cooling system maintains optimal operating temperatures for the laser source and other components, preventing overheating. It’s especially critical for continuous or high-power marking applications, as it prolongs the machine’s lifespan and maintains consistent marking quality.

- Safety Enclosures and Interlocks: Safety enclosures shield operators from laser radiation, while interlock systems ensure the laser cannot operate if the enclosure is open. This setup guarantees a safe working environment and compliance with safety regulations.

The Laser Marking Process

Laser marking involves several precise steps, from design to quality inspection.

- Design and Programming: The marking design, which could include text, logos, or complex patterns, is created using computer software. The design is then programmed into the laser marking machine, determining the path and intensity of the laser beam.

- Material Preparation: The material is cleaned and positioned securely on the workpiece handling system. Any surface contaminants are removed to ensure consistent marking quality.

- Parameter Setting: Key parameters, such as laser power, speed, frequency, and pulse duration, are set based on the material type and desired marking effect. This step is essential for achieving optimal marking quality and durability.

- Laser Beam Generation: The laser source generates a coherent, intense beam of light with specific properties suitable for marking. The type of laser selected (fiber, CO2, UV) depends on the material and the marking requirements.

- Beam Focusing: The laser beam is focused to a fine spot size using lenses, creating high energy density that enables accurate and deep marking. Focusing is crucial for creating high-resolution markings.

- Beam Steering: The galvanometer scanners rapidly move the focused beam across the material’s surface following the programmed path, achieving the desired marking pattern at high speeds.

- Material Interaction: The laser beam interacts with the material surface, causing localized changes such as heating, melting, or ablation. This interaction alters the material’s color, texture, or surface structure, creating the visible mark.

- Cooling and Solidification: As the laser completes marking, the material cools rapidly, solidifying the marked pattern and ensuring a permanent, durable result.

- Quality Inspection: The marked product undergoes inspection to confirm that the markings meet quality standards for clarity, precision, and durability.

Physics Behind Laser Marking

The laser marking process relies on fundamental physical interactions between the laser beam and the material.

- Absorption of Laser Energy: When the laser beam hits the material, the surface absorbs its energy, causing localized heating. The rate of absorption depends on the material and the laser’s wavelength; for example, metals absorb infrared laser energy effectively, while UV lasers are better suited for plastics.

- Localized Heating: The absorbed energy generates intense, localized heat, which causes changes in the material’s structure. Depending on the process and material, this heat may cause oxidation, color change, or surface melting.

- Material Removal (Ablation): In some marking processes, such as engraving, the laser energy is strong enough to vaporize material, creating grooves or recesses. This ablation is a non-contact method that avoids wear on the marking tool and enables intricate, precise designs.

- Chemical Reactions: The heat generated by the laser can cause chemical changes, such as oxidation, which alters the material’s color without removing any material. For example, annealing marking on stainless steel uses oxidation to create black or dark-colored marks.

- Phase Changes: Some materials undergo phase changes, such as from solid to gas, during laser marking. This rapid transformation affects the material’s texture and appearance, allowing for distinct and durable markings.

Types of Laser Marking Processes

Annealing Marking

Annealing marking involves heating the metal surface to induce oxidation, which changes the color of the material without removing any of it. This process typically results in a dark mark, with colors ranging from brown to black depending on the oxidation level.

- Materials: Primarily used on metals such as stainless steel, titanium, and other alloys.

- Applications: Common in medical and surgical instruments, as well as automotive and aerospace parts, where surface integrity is crucial.

- Advantages: Since annealing does not remove material, it preserves the surface and is ideal for applications where a smooth, corrosion-resistant finish is required.

Etching/Engraving

Etching and engraving are processes where the laser removes material from the surface. Etching involves shallow removal, whereas engraving penetrates deeper into the material.

- Materials: Suitable for metals, plastics, and ceramics.

- Applications: Widely used in industries that require durable and wear-resistant markings, such as the automotive, jewelry, and electronics industries.

- Advantages: Produces highly durable, tactile marks that can withstand rough handling and exposure to harsh conditions. The depth of the marking also adds security for traceability and anti-counterfeiting purposes.

Carbon Migration

Carbon migration is a process that involves heating metal surfaces to draw carbon to the surface, creating a dark, high-contrast mark. The laser does not remove material but instead causes a molecular change that results in a visible mark.

- Materials: Commonly used on metals with carbon content, such as steel alloys.

- Applications: Ideal for creating dark marks on metals, often in applications where high contrast and durability are needed, such as in tool and part identification.

- Advantages: Produces a high-contrast, permanent mark without removing material, making it an excellent choice for applications that require a clean surface with strong visual impact.

Foaming

Foaming is a laser marking technique primarily used on plastics and some metals. The laser melts the material, creating small gas bubbles trapped within it as it cools. This process produces a raised, light-colored mark with a frothy appearance.

- Materials: Most effective on dark plastics and certain metals.

- Applications: Often used for high-contrast marking on plastics, such as packaging, consumer goods, and electronic components.

- Advantages: The contrast between the foamed and non-foamed areas provides a highly visible mark, making it easy to read, even on darker materials.

Color Change

The color change process relies on the laser causing a molecular or chemical alteration within the material without affecting its surface texture. This technique is particularly useful for plastics, as it changes the material’s color without deformation.

- Materials: Commonly used for plastics and some metals.

- Applications: Ideal for items that require a subtle but clear mark, such as circuit boards, medical devices, and consumer electronics.

- Advantages: Creates a high-contrast mark without damaging the material’s surface, making it suitable for delicate parts and aesthetic marking applications.

Surface Ablation

Surface ablation involves the laser removing a thin layer of material, such as paint, anodized coatings, or other surface treatments, to reveal the underlying substrate. This process is effective for creating contrast by exposing different material layers.

- Materials: Works well on coated metals and plastics.

- Applications: Widely used for “day-night” markings on buttons and switches, where backlighting is required, as well as for creating permanent marks on painted surfaces.

- Advantages: Allows for precise, high-contrast marking by exposing different layers, useful in automotive interiors, control panels, and any application that requires legible markings in variable lighting.

Types of Laser Sources Used in Marking Machines

Fiber Lasers

Fiber lasers use optical fibers doped with rare-earth elements, such as ytterbium, to generate a high-intensity laser beam. They are highly efficient and capable of delivering stable, continuous operation with minimal maintenance requirements.

- Wavelength: Approximately 1064 nm (infrared).

- Markable Materials: Fiber lasers are especially effective on metals, including stainless steel, aluminum, copper, brass, and other alloys. They can also mark some types of plastics.

- Applications: Widely used for marking automotive parts, electronic components, tools, and medical devices. They are ideal for engraving, etching, and annealing metals.

- Advantages:

- High Beam Quality: Fiber lasers produce fine, high-resolution marks, making them suitable for intricate designs and small text.

- Long Service Life: Fiber lasers are robust and can last up to 100,000 hours, with minimal maintenance.

- Efficiency: High energy efficiency results in reduced operating costs.

- Non-Contact and Fast Marking: Provides high-speed marking with no physical contact, ensuring low wear and tear on the machine.

CO2 Lasers

CO2 lasers generate laser beams by exciting a gas mixture primarily made of carbon dioxide, nitrogen, and helium. CO2 lasers operate in the far-infrared spectrum, which is ideal for marking non-metallic and organic materials.

- Wavelength: Approximately 10,600 nm (far-infrared).

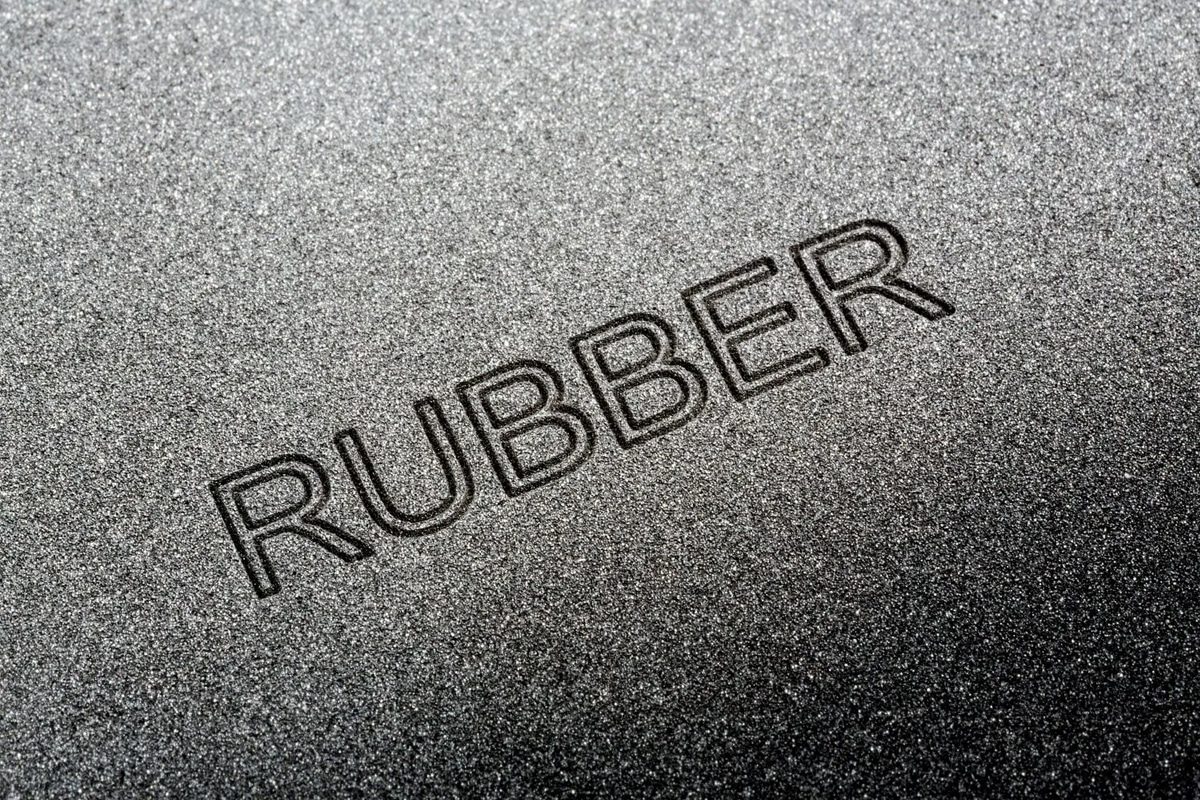

- Markable Materials: Effective for non-metals, including wood, glass, paper, textiles, leather, rubber, acrylic, and certain plastics.

- Applications: Commonly used in industries that work with organic materials, such as packaging, signage, textile processing, and woodworking. CO2 lasers are well-suited for applications requiring engraving, cutting, and surface marking.

- Advantages:

- Versatility with Non-Metals: CO2 lasers excel at marking and cutting non-metallic materials that other lasers struggle with.

- High Power for Cutting and Engraving: They can be used for both marking and cutting thicker organic materials.

- Low Cost of Ownership: CO2 lasers generally have a lower initial cost and are relatively easy to maintain.

- Minimal Thermal Effect: Produces clean marks with limited heat-affected zones, which is beneficial for materials prone to warping.

UV Lasers

UV lasers operate at a short wavelength, producing a “cold” laser marking effect. The short wavelength reduces the amount of heat transferred to the material, which is ideal for applications requiring high precision and minimal thermal impact.

- Wavelength: Approximately 355 nm (ultraviolet).

- Markable Materials: Highly effective on sensitive materials such as plastics, glass, ceramics, and certain metals. They also work well on heat-sensitive materials and surfaces that require precise, high-contrast markings.

- Applications: UV lasers are commonly used for marking in the electronics industry, medical device manufacturing, and the cosmetics industry. They are ideal for marking circuit boards, plastic components, glass bottles, and medical packaging.

- Advantages:

- Minimal Heat-Affected Zone: UV lasers produce a cold marking effect that prevents damage to delicate materials.

- Precision and Clarity: High-contrast marks with fine resolution, suitable for intricate graphics, small fonts, and serial numbers.

- Low Thermal Deformation: Suitable for heat-sensitive materials without risking melting, discoloration, or damage.

- High Absorption Rate in Plastics: UV wavelengths are highly absorbed by plastics, allowing for clear and high-contrast marks.

Green Lasers

Green lasers operate at a wavelength in the visible spectrum, making them highly effective for marking reflective materials that are challenging to mark with infrared lasers. Green lasers have good penetration and precision, especially useful for certain metals and transparent materials.

- Wavelength: Approximately 532 nm (green).

- Markable Materials: Suitable for reflective metals such as copper, silver, and gold, as well as certain types of plastics, ceramics, and glass.

- Applications: Green lasers are used in industries requiring fine detail on reflective materials, such as electronics, jewelry, and medical equipment. They’re ideal for applications requiring minimal heat transfer, such as circuit board marking and jewelry personalization.

- Advantages:

- Effective on Reflective Materials: Can mark challenging, highly reflective materials that absorb less infrared energy.

- High Precision: Produces finely detailed marks suitable for small fonts and intricate designs.

- Lower Thermal Impact: Reduces the risk of thermal damage to the workpiece, preserving material properties.

- Cold Marking on Heat-Sensitive Materials: Ensures high-quality marks on materials like glass without cracking or chipping.

Applications of Laser Marking Machines

Automotive Industry

In the automotive industry, precision and traceability are crucial. Laser marking machines are used to mark a variety of components, such as engine parts, brake systems, and VIN (Vehicle Identification Number) plates. These permanent markings help ensure that each part is traceable throughout its lifecycle, aiding in maintenance, recall processes, and counterfeit prevention.

- Typical Markings: Serial numbers, barcodes, part numbers, logos.

- Benefits: Enhances traceability, improves safety, and complies with industry regulations.

Electronics and Semiconductors

In electronics and semiconductor manufacturing, laser marking is widely used for labeling delicate components, such as printed circuit boards (PCBs), connectors, and chips. Laser marking provides high contrast without damaging sensitive electronic parts, ensuring clear identification while maintaining product integrity.

- Typical Markings: QR codes, serial numbers, and tiny alphanumeric characters.

- Benefits: Allows for precise, high-contrast markings on small components, essential for inventory management and quality control.

Medical Devices

Laser marking is indispensable in the medical device industry, where accuracy and safety are paramount. Medical tools, surgical instruments, and implants are marked with unique device identification (UDI) codes, batch numbers, and logos. Since laser marking is biocompatible and corrosion-resistant, it meets the stringent regulatory standards in the healthcare sector.

- Typical Markings: UDIs, batch numbers, and company logos.

- Benefits: Provides permanent, sterile markings that withstand sterilization processes, ensuring compliance with healthcare regulations and improving patient safety.

Aerospace Industry

The aerospace industry requires durable markings for critical components, as these parts are often exposed to extreme conditions. Laser marking ensures that markings on aircraft parts remain legible and permanent, enabling reliable tracking and maintenance. Aerospace components like turbine blades, fasteners, and structural parts are marked with serial numbers and tracking codes.

- Typical Markings: Serial numbers, part IDs, and tracking codes.

- Benefits: Offers durable, wear-resistant markings that can withstand harsh environments and rigorous quality standards.

Jewelry and Luxury Goods

Laser marking is widely used in the jewelry and luxury goods industry for adding intricate designs, personalization, and branding on precious metals, gemstones, and luxury items. It allows jewelers to create high-quality, detailed marks without compromising the integrity of valuable materials.

- Typical Markings: Custom designs, logos, serial numbers, and hallmarks.

- Benefits: Provides elegant, detailed, and customizable markings without physical contact, adding value and anti-counterfeiting measures to high-end products.

Tool Manufacturing

Laser marking is essential in tool manufacturing for identifying tools with specifications, brand logos, and serial numbers. This helps customers identify tools quickly and allows manufacturers to track product batches for quality control purposes.

- Typical Markings: Model numbers, dimensions, logos, and batch numbers.

- Benefits: Enables durable markings that withstand rough handling and wear, enhancing traceability and quality assurance.

Packaging Industry

In the packaging industry, laser marking is used to create expiration dates, batch numbers, and barcodes on packaging materials. This helps with traceability, inventory control, and regulatory compliance. Laser marking is non-contact and clean, making it ideal for marking a wide variety of packaging materials.

- Typical Markings: Expiration dates, barcodes, and batch numbers.

- Benefits: Provides clear, permanent markings that meet regulatory standards and maintain quality, even under environmental stress.

Consumer Goods

Laser marking is extensively used in the consumer goods sector to personalize items, add brand logos, and engrave unique identifiers on products such as mobile phones, laptops, and accessories. Laser marking’s flexibility allows manufacturers to add high-quality, detailed designs on various materials.

- Typical Markings: Logos, barcodes, serial numbers, and decorative elements.

- Benefits: Offers durable and high-quality personalization options, enhancing brand value and preventing counterfeiting.

Defense and Military

In the defense and military sectors, laser marking is crucial for marking and tracking equipment, firearms, and other assets. The permanent, high-contrast marks help with inventory control, asset management, and compliance with military standards.

- Typical Markings: Serial numbers, barcodes, and asset identifiers.

- Benefits: Provides robust markings that withstand extreme conditions, ensuring reliability and compliance with military regulations.

Advertising and Signage

Laser marking is ideal for creating customized signs, displays, and promotional items with high-quality graphics and text. The technology allows for intricate detailing on materials like acrylic, metal, and wood, providing clear, long-lasting marks that enhance the visual appeal of advertising materials.

- Typical Markings: Logos, graphics, and decorative text.

- Benefits: Offers detailed, high-contrast markings that catch the eye, making it perfect for branding and promotional use.

Advantages of Laser Marking Machines

Laser marking machines offer numerous benefits over traditional marking methods, making them an essential tool for modern manufacturing across various industries.

- High Precision and Quality: Laser marking provides unparalleled precision and detail, allowing manufacturers to create intricate designs, small fonts, and high-resolution graphics with exceptional clarity. The laser beam is highly focused, ensuring consistent and accurate markings that enhance readability and aesthetic quality. This precision is especially beneficial for applications requiring detailed logos, barcodes, or serial numbers on small components, such as electronic parts or medical devices.

- High Speed and Efficiency: Laser marking machines operate at high speeds, making them ideal for production environments where time is critical. They can mark products within seconds, significantly increasing productivity and throughput. With minimal downtime required for maintenance, laser marking machines support efficient, continuous operation, reducing lead times and optimizing the manufacturing process.

- Permanent and Durable Marks: The marks created by laser marking are permanent and highly durable, capable of withstanding harsh environments, abrasion, and exposure to chemicals. This durability ensures that identification markings, such as serial numbers and batch codes, remain intact throughout a product’s lifecycle. This advantage is particularly important for industries like automotive, aerospace, and medical devices, where component traceability and quality assurance are essential.

- Non-Contact Process: Laser marking is a non-contact process, meaning the laser beam interacts with the material without physically touching it. This approach minimizes wear and tear on both the machine and the workpiece, preserving the integrity of delicate or sensitive materials. The non-contact nature of laser marking also reduces the risk of material deformation, making it ideal for fragile or thin materials.

- Versatility: Laser marking machines are highly versatile and can mark a wide variety of materials, including metals, plastics, ceramics, glass, wood, and textiles. Different laser sources—such as fiber, CO2, UV, and green lasers—make it possible to mark both hard and soft materials with the same level of precision. This versatility allows manufacturers to address diverse marking needs within a single production line.

- Flexibility: Laser marking machines offer flexibility in both design and operation. With computer-controlled software, users can easily switch between different designs, logos, or text without changing tools or setups. This capability is valuable for small-batch production or personalized marking, allowing businesses to quickly adapt to varying customer demands and product specifications.

- Low Operating Costs: Once installed, laser marking machines incur minimal ongoing costs. Unlike traditional methods, laser marking does not require consumables such as inks, chemicals, or engraving tools, which leads to substantial savings over time. Additionally, with few moving parts, laser marking machines require minimal maintenance, contributing to lower long-term operational costs.

- Environmentally Friendly: Laser marking is a clean process that does not involve hazardous chemicals or produce significant waste. By eliminating the need for inks, solvents, and other consumables, laser marking reduces environmental impact and aligns with sustainable manufacturing practices. The process also generates minimal noise and dust, making it a safer and more eco-friendly solution for marking needs.

- Automation and Integration: Laser marking machines can be easily integrated into automated production lines, making them suitable for high-volume manufacturing. Many laser marking systems are compatible with robotic handling systems and programmable logic controllers (PLCs), enabling seamless operation and consistent marking quality. This compatibility with automated workflows supports mass production, enhances consistency, and allows manufacturers to scale efficiently.

Limitations and Challenges

While laser marking machines offer numerous advantages, they also come with certain limitations and challenges. Understanding these can help manufacturers make informed decisions and prepare for the necessary considerations before integrating laser marking into their production processes.

- Initial Investment: Laser marking machines require a significant upfront investment compared to traditional marking methods like inkjet printing or stamping. High-quality laser marking systems, especially those with advanced capabilities such as fiber or UV lasers, can represent a substantial cost. This initial expense includes not only the machine but also the setup, software, and training for operators. For smaller companies or those with limited budgets, the cost can be a barrier to adoption. However, the long-term cost savings from low operating costs and minimal maintenance can often offset the initial investment.

- Material Limitations: While laser marking machines can handle a wide range of materials, certain materials remain challenging or incompatible with laser marking. For example, reflective metals like copper and gold require specific types of lasers, such as green lasers, which can add to costs. Additionally, materials with high heat sensitivity, like some thermoplastics, may be prone to deformation or discoloration when exposed to laser marking, even with low-energy settings. In these cases, adjustments in laser parameters or alternative marking methods may be required.

- Safety Considerations: Laser marking machines produce high-energy beams, which can pose safety risks if not properly managed. Operators and bystanders need protection from potential laser exposure, which can cause eye or skin injuries. Safety precautions, such as using protective enclosures, interlocks, and laser safety eyewear, are essential to minimize risks. Additionally, laser marking of certain materials may produce fumes or particulates, requiring appropriate ventilation or fume extraction systems to maintain air quality and ensure operator safety.

- Technical Expertise: Operating laser marking machines and achieving optimal results requires a level of technical expertise. Adjusting laser parameters—such as power, frequency, and speed—according to the material and desired marking effect can be complex and may require specialized knowledge. Furthermore, designing and programming markings, especially intricate graphics or high-precision text, demands familiarity with laser marking software. Without the necessary training and expertise, companies may struggle to fully leverage the capabilities of laser marking machines, resulting in suboptimal marks or longer production times.

Considerations When Choosing a Laser Marking Machine

Selecting the right laser marking machine is essential to ensure that it meets your production needs, quality standards, and budget. Here are key considerations to guide your decision-making process:

- Material Type: Different laser types are suited for different materials. For instance, fiber lasers are ideal for metals, while CO2 lasers work best with organic materials like wood, plastic, and glass. If your production line involves multiple materials, you may need a versatile laser marking machine or multiple laser sources to handle a range of substrates efficiently.

- Marking Requirements: Determine the type of marking you need, whether it’s deep engraving, high-contrast marking, or fine-line work. Some applications may require etching or engraving, while others may only need surface marking or color change. Understanding your specific marking requirements will help you choose the appropriate laser power, wavelength, and processing capabilities to achieve the desired results.

- Production Volume: For high-volume production, speed and efficiency are crucial. Laser marking machines come with varying speeds and capabilities; some are built for quick batch processing, while others are designed for detailed, slower marking. Choose a machine that can handle your production volume without sacrificing quality or speed. Automated handling systems can also improve efficiency in high-volume environments.

- Precision and Detail: If your applications require intricate designs, small fonts, or high-precision marks, you’ll need a machine with high-resolution marking capabilities. The beam quality, focus precision, and scanning speed will all influence the level of detail you can achieve. Applications in the medical, electronics, and luxury goods sectors often require this high degree of precision.

- Integration and Automation: Consider whether the laser marking machine needs to integrate with your existing production line. Many laser marking systems support automation through programmable logic controllers (PLCs) and are compatible with robotic arms or conveyors. For large-scale or high-volume operations, automated integration can streamline processes, reduce errors, and maintain consistent marking quality.

- Software Capabilities: Laser marking machines are operated through control software that manages design creation, parameter adjustments, and automation functions. Ensure the software is user-friendly and supports the file formats you need (e.g., DXF, PLT, BMP) for your designs. Advanced software can also allow for real-time adjustments, serialization, and even integration with database systems for dynamic marking needs.

- Cost and Budget: The cost of a laser marking machine can vary significantly based on the laser type, power, and features. Set a realistic budget, considering not only the initial purchase price but also ongoing operational costs, such as maintenance and energy consumption. While higher-end models may offer advanced capabilities, it’s essential to evaluate whether these features align with your production goals and provide a clear return on investment.

- After-Sales Support and Service: Reliable after-sales support can be invaluable, particularly when operating complex laser equipment. Choose a manufacturer or supplier that offers comprehensive support services, including installation, training, troubleshooting, and maintenance. Quality after-sales service ensures that your machine remains in optimal condition and reduces downtime in case of issues.

- Regulatory Compliance: Depending on your industry, specific regulatory standards may apply to laser-marked products. For example, medical devices require Unique Device Identification (UDI) markings, while automotive parts often need standardized identification codes. Ensure that the machine you choose can meet industry-specific regulations and maintain compliance with health and safety standards.

- Future Expansion: As your business grows, your production needs may increase, requiring more powerful or versatile marking capabilities. Look for machines that offer upgrade options or modular designs, allowing you to add new functionalities or increase power when needed. Investing in a machine with scalability ensures you can meet future demands without needing a complete replacement.

Summary

Get Laser Marking Solutions

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.