$4,000.00 – $8,700.00

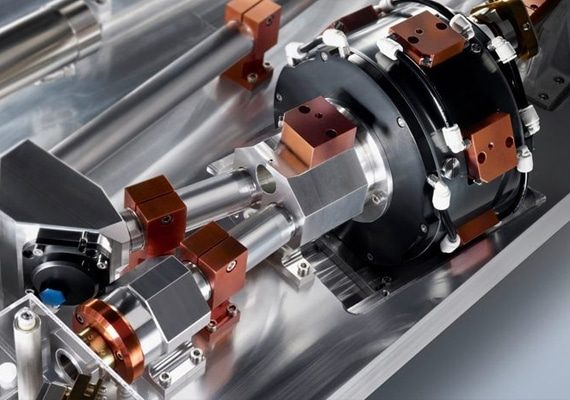

Our laser welding machines are equipped with high-quality laser generators that ensure excellent beam quality, providing small and focused spot sizes for precise and efficient welding. With power output options from 1500w to 3000w, our laser welding machines can meet a variety of welding needs, ensuring optimum productivity without compromising quality.

Designed with reliability in mind, our laser welding machines feature an efficient water cooling system to ensure consistent performance and extend the life of the laser generator. With advanced water cooling technology, we can guarantee stable and reliable welding results even during long-term operation.

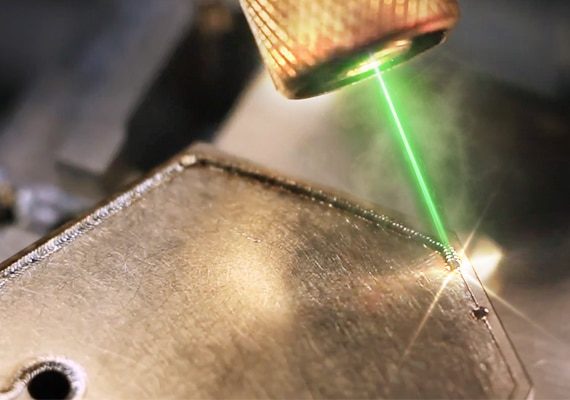

Our laser welding machines have excellent beam quality, producing a focused and precise laser spot. This feature enables high-precision and efficient welding of different materials and thicknesses, reducing spatter and minimizing the heat-affected zone.

The beam delivery system of our laser welding machines utilizes flexible and flexible fiber optic cables, which can be easily integrated into automated production lines or robotic systems, enabling you to flexibly and easily adapt to different welding tasks. This flexibility increases workflow efficiency and seamlessly adapts to various manufacturing settings.

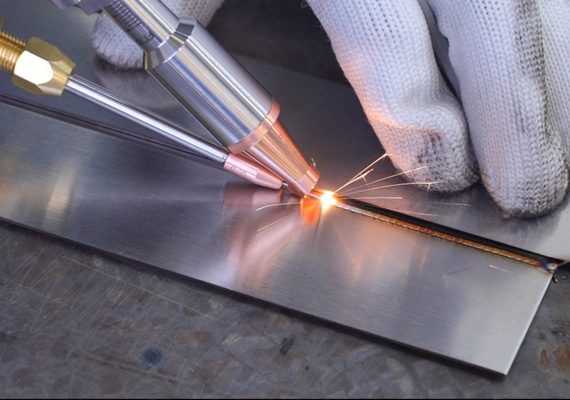

Our laser welding machines feature a user-friendly control interface that gives you complete control over your welding process. Easily adjust and program welding parameters such as power, pulse duration, welding speed, and focus position to obtain the best results for your specific welding requirements.

Our laser welding machines are equipped with comprehensive safety features including enclosures, interlock systems, and safety sensors. These measures protect your operators from potential exposure to the laser beam, creating a safe work environment.

| Model | AKH-1000 | AKH-1500 | AKH-2000 | AKH-3000 |

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Range of Adjustable Power | 1-100% | |||

| Laser Wavelength | 1080nm | |||

| Way of Working | Continuous/Modulation | |||

| Cooling Method | Water Cooling | |||

| Power Demand | AC220V±5%/50Hz | |||

| Working Environment Temperature | 15~35℃ | |||

| Working Environment Humidity | < 70%(No Condensation) | |||

| Laser Power (W) | Welding Form | Thickness (mm) | Welding Speed (mm/s) | Defocus Amount | Protective Gas | Blowing Method | Flow (L/min) | Welding Effect |

|---|---|---|---|---|---|---|---|---|

| 1000 | Butt Welding | 0.5 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | -1.0 | Welded Completely | |

| 1500 | Butt Welding | 0.5 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 2000 | Butt Welding | 0.5 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 50~60 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 30~40 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| 3000 | Butt Welding | 0.5 | 100~110 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Butt Welding | 1 | 90~100 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 1.5 | 80~90 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 2 | 70~80 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 3 | 60~70 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely | |

| Butt Welding | 4 | 40~50 | -1~1 | Ar | Coaxial/Paraaxial | 5~10 | Welded Completely |

| Welding Method | Laser Welding | TIG Welding | MIG Welding |

|---|---|---|---|

| Heat Source | Highly focused laser beam | Non-consumable tungsten electrode | Consumable electrode and filler wire |

| Heat Input | Very concentrated and precise | Precise control of heat input | High heat input, less precise |

| Welding Speed | High welding speed | Slower compared to MIG | High welding speed |

| Distortion | Minimal distortion and warping | Low heat input, less distortion | More prone to distortion |

| Penetration | Limited on thicker materials | Limited on thicker materials | Good penetration on thicker materials |

| Weld Quality | High-quality, narrow heat-affected zone | High-quality welds with good aesthetics | Good quality, but not as precise as TIG |

| Material | Suitable for thin materials | Suitable for thin to medium-thickness | Suitable for a wide range of thicknesses |

| Operator Skill | Requires skilled operators | Requires skilled operators | Easier to learn and use |

| Automation | Suitable for automation | Manual process, but can be automated | Highly suitable for automation |

| Joint Types | Suitable for various joint types | Suitable for various joint types | Suitable for various joint types |

| Shielding Gas | Generally, no shielding gas is required | Requires shielding gas (e.g., Argon) | Requires shielding gas (e.g., CO2) |

| Spatter | Minimal spatter | No spatter | Minimal spatter |

| Equipment Cost | High initial equipment cost | Moderate equipment cost | Relatively lower equipment cost |

Note: The information provided in the table is a general comparison of the three welding methods when used for welding stainless steel. The actual performance of each method may vary based on specific project requirements, material thickness, and the expertise of the welder. It’s essential to consider these factors while choosing the appropriate welding method for a particular application.

Yes, laser welding machines are very effective at welding stainless steel. Stainless steel is one of the most commonly welded materials with laser welding techniques. Laser welding offers several advantages when working with stainless steel, making it a popular choice for a variety of industrial applications. The stainless steel laser welding machine utilizes fiber laser technology to produce a focused and precise laser beam. This concentrated energy enables deep penetration welding of stainless steel, ensuring a strong and reliable weld.

At present, laser welding has become the preferred method for joining stainless steel parts in automotive, aerospace, medical equipment, kitchenware, electronics, and other industries. Whether it is precision welding of small stainless steel parts or high-speed welding of large structural components, laser welding machines provide efficient and reliable solutions for the processing of stainless steel materials.

Stainless steel is a versatile material, available in a variety of grades and alloys, each with its unique properties. Laser welding machines can typically weld a variety of stainless steel types, but specific capabilities may depend on the machine’s power, settings, and type of laser used. Here are some common types of stainless steel that can typically be welded using a laser welding machine:

When considering a stainless steel laser welding machine, you must ensure that the machine is sized appropriately for the specific grade of stainless steel you wish to weld. Some stainless steel alloys may require specific welding parameters for optimal results. You can consult with an AccTek Laser engineer to determine compatibility with the types of stainless steel you plan to weld and get advice on setup and techniques for achieving high-quality welds.

The cost of a stainless steel laser welding machine can vary widely, depending on various factors such as the machine’s specifications, power output, features, brand reputation, and the supplier you choose. Generally, a stainless steel laser welding machine is considered a great investment in an industrial setting due to the advanced technology and features involved.

According to a rough estimate, the cost of a stainless steel laser welding machine can range from several thousand dollars to tens of thousands of dollars. For example, the cost of a 1500w laser welding machine is between US$4,500 and US$13,000, while the price of a 3000w laser welding machine integrated with an automated robot is between US$15,000 and US$50,000.

It should be noted that the purchase cost of the machine is only a part of the overall investment. Other factors to consider include installation, training, maintenance, and ongoing operating costs such as power consumption and consumables such as shielding gas. In addition, it is recommended to consider the long-term return on investment (ROI) in terms of increased productivity, improved weld quality, and reduced operating costs.

If you want to get an accurate and latest price, you can contact us directly. AccTek Laser, as an experienced laser welding machine manufacturer, can provide you with a custom quote based on your specific requirements and take you through an in-depth look at the features and benefits of each machine model within your budget. In addition, we will also provide you with a 3-year warranty, technical support, and good after-sales service. Contact us for the best solution and quote for you!

In stainless steel laser welding, shielding gas is used to protect the weld pool and prevent oxidation and contamination during the welding process. The choice of shielding gas affects weld quality and overall weld performance. The gases most commonly used when laser welding stainless steel are:

The choice of gas depends on the specific requirements of the welding application, the grade of stainless steel being welded, and the desired weld quality and penetration. In some cases, gas mixtures such as argon-helium or argon-nitrogen can be used to achieve the desired welding results.

Proper gas flow rate and nozzle design are also important factors to consider to ensure effective gas coverage of the weld pool and avoid excessive turbulence during welding. Welding parameters, including gas flow rate and focus position, are typically adjusted during laser welding to achieve the best results for specific materials and joint configurations.

The maximum thickness of stainless steel that a laser welder can weld depends largely on the power of the laser. Here is a general breakdown based on laser power:

These specifications outline the thickness range over which stainless steel can be effectively welded at each laser power level. It is important to note that these are general guidelines only and actual performance may vary based on factors such as material composition, joint design, welding speed, and other process parameters.

With years of experience in laser welding technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser welding machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser welding machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser welding machine is rigorously tested and adhered to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect welds every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser welding machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for Stainless Steel Laser Welding Machine

Mai –

Impressive precision and reliability. Boosts productivity in our manufacturing process. Great investment for our business.

Saanvi –

Reliable performance, and consistent weld quality. Simplifies complex welding jobs. Highly recommended for industrial use.

Stjepan –

Effortlessly handles intricate welds. Saves time and improves efficiency. Essential for our production workflow.

Grâce –

Streamlines our welding process. Easy to operate, delivers high-quality welds consistently. A valuable addition to our workshop.