Laser cleaning machines have become essential in various industries due to their ability to provide precise, efficient, and environmentally friendly cleaning solutions. These machines use concentrated laser beams to remove contaminants like rust, paint, grease, and oxides from surfaces, all without damaging the underlying material. Industries such as aerospace, automotive, electronics, and manufacturing benefit greatly from this non-contact, non-abrasive technology, as it reduces waste, enhances surface preparation, and ensures higher-quality finishes. Unlike traditional methods that involve chemicals or abrasive materials, laser cleaning is safer for both operators and the environment. This article explores the diverse applications of laser cleaning machines across different industries, emphasizing their advantages in terms of precision, sustainability, and cost-effectiveness. By integrating this innovative technology, industries can improve productivity, enhance safety, and reduce environmental impact, all while achieving superior cleaning results.

Laser cleaning is a highly efficient process that uses focused laser beams to remove unwanted materials, such as rust, paint, grease, or contaminants, from the surface of an object without damaging the base material. The laser beam is directed onto the surface, where it interacts with the contaminants, causing them to either vaporize or be ejected from the surface due to rapid heating. The underlying material remains unaffected due to the precision and controllability of the laser’s energy. This process is non-contact, non-abrasive, and leaves no secondary waste, making it ideal for industries that require a clean and safe environment.

The key to effective laser cleaning lies in selecting the correct laser parameters, such as wavelength, energy density, pulse duration, and repetition rate. These parameters determine how efficiently the contaminants absorb the laser energy and how effectively they are removed. The laser’s energy needs to be strong enough to vaporize or dislodge the contaminant but gentle enough to avoid altering or damaging the substrate.

The choice between continuous wave and pulsed laser technology depends on the specific cleaning requirements, material properties, and the type of contaminants to be removed.

Laser cleaning technology operates by carefully balancing the interaction between the laser’s energy and the contaminant to achieve effective and efficient cleaning. By choosing the correct laser type and adjusting the laser parameters, industries can achieve precise cleaning results, maintain the integrity of the base material, and avoid secondary waste or damage to the environment.

Laser cleaning has gained wide acceptance across various industries due to its precision, efficiency, and environmentally friendly nature. It involves the use of laser beams to remove contaminants such as rust, paint, grease, and other unwanted materials from surfaces without causing damage to the base material. This non-contact, non-abrasive method is versatile and effective in a range of applications across different sectors.

In the automotive sector, laser cleaning is used for several key tasks, including the removal of rust and paint, surface preparation for welding, and cleaning of molds and tools. Laser cleaning offers an efficient way to restore car bodies and parts during manufacturing and restoration projects. By providing precise surface preparation, laser cleaning ensures stronger weld joints and better-quality coatings. It also eliminates the need for abrasive techniques that could damage surfaces, increasing productivity and reducing operational costs.

The aerospace industry requires extremely high standards of cleanliness and precision. Laser cleaning plays a critical role in removing contaminants such as oxides, coatings, and other residues from sensitive components like engine parts, landing gear, and structural elements. Additionally, laser cleaning is used for surface preparation before painting or bonding. The non-abrasive nature of laser cleaning helps protect delicate surfaces while providing the clean, contaminant-free surface needed to maintain high-quality aerospace products.

In manufacturing and metal processing, laser cleaning is often used to prepare surfaces for welding, coating, or bonding. It can remove rust, grease, and other residues from metal components, ensuring high-quality and durable finishes. Laser cleaning is particularly beneficial in industries that process metals such as steel and aluminum, where maintaining the integrity of the material is crucial. It is also ideal for cleaning equipment and tools used in manufacturing, extending their life span by reducing wear and tear.

The power generation industry, including renewable energy, relies on large equipment that needs to be maintained and cleaned regularly to ensure operational efficiency. Laser cleaning provides an effective method for removing rust, scale, and other contaminants from turbines, pipes, and boilers. It can also be used for cleaning sensitive components in nuclear power plants, where the precision and minimal waste generation of laser cleaning are especially important. The technology helps extend the life of equipment and reduces the need for chemical-based cleaning methods that can harm the environment.

In the highly sensitive electronics and semiconductor industry, laser cleaning is essential for the precision cleaning of components. It is used to remove flux residues, oxides, and particles from connectors, circuit boards, and semiconductor wafers. Laser cleaning ensures that delicate electronic components remain undamaged while achieving a contaminant-free surface, improving product quality and reliability. The process is non-contact, making it suitable for the intricate cleaning tasks required in microelectronics manufacturing.

Laser cleaning technology is also used in art and cultural heritage preservation to carefully remove layers of dirt, pollution, and overpainting from valuable artworks, sculptures, and historical monuments. The precision of laser cleaning allows conservators to selectively remove unwanted materials without damaging the original surfaces. This method has been used in the restoration of famous historical landmarks, providing a clean and safe way to preserve cultural artifacts for future generations.

In industries that use molds for production, such as tire manufacturing, laser cleaning is used to clean molds without damaging their surfaces. Over time, rubber, plastic, or composite residues accumulate in molds, affecting product quality. Laser cleaning offers a non-abrasive way to remove these residues, reducing downtime and extending mold life. It can also clean tools and equipment, improving overall production efficiency and reducing maintenance costs.

The oil and gas industry uses large-scale machinery and pipelines that require regular maintenance to avoid contamination, rust, or corrosion. Laser cleaning provides a safe and efficient method to clean pipelines, valves, and equipment. It effectively removes contaminants like grease, oil, and oxides from surfaces, reducing the risk of equipment failure and improving safety standards. By eliminating the need for hazardous chemical cleaning agents, laser cleaning also reduces environmental impact and helps ensure compliance with industry regulations.

In the nuclear industry, decontaminating radioactive surfaces is a major challenge. Laser cleaning is a preferred solution for this application because it reduces the volume of radioactive waste while providing a non-contact, non-abrasive method to remove contaminants. This process is safer for operators and more precise, allowing nuclear facilities to clean equipment and surfaces while minimizing exposure to radiation and reducing hazardous waste generation.

The versatility, precision, and environmental benefits of laser cleaning technology have made it indispensable across various industries. From automotive and aerospace to nuclear power and cultural heritage, laser cleaning provides an efficient and safe solution for removing contaminants without damaging the underlying material. Its non-contact, non-abrasive nature, along with minimal waste generation, positions laser cleaning as a superior alternative to traditional cleaning methods, helping industries enhance productivity, reduce costs, and improve safety.

Laser cleaning technology offers numerous advantages over traditional cleaning methods, making it increasingly popular in various industrial applications. Its precision, efficiency, and environmental benefits make it a superior choice for industries that require thorough, safe, and cost-effective cleaning solutions.

One of the most significant benefits of laser cleaning is that it is non-abrasive, meaning that it does not wear down or damage the underlying material. Unlike abrasive techniques such as sandblasting or mechanical scraping, which can cause surface degradation over time, laser cleaning uses focused laser beams to remove contaminants gently. This makes laser cleaning ideal for industries dealing with sensitive or delicate components, such as electronics, aerospace, and cultural heritage conservation, where the integrity of the substrate needs to be protected.

Laser cleaning offers unmatched precision, allowing operators to selectively remove contaminants without affecting the surrounding areas or base material. This level of control is essential in applications requiring meticulous cleaning, such as in the semiconductor and electronics industries, where even microscopic particles can compromise product quality. The ability to precisely target contaminants makes laser cleaning ideal for intricate surfaces or areas that are difficult to access with traditional cleaning methods.

Unlike chemical cleaning methods, which often involve the use of hazardous solvents and produce large amounts of waste, laser cleaning is an environmentally friendly process. It eliminates the need for harmful chemicals, reducing the risk of environmental contamination and the need for special disposal procedures. Additionally, laser cleaning generates minimal secondary waste, as the material removed by the laser can be collected easily, making the process much cleaner and safer for both the environment and operators.

While the initial investment in laser cleaning equipment may be higher than traditional methods, the long-term cost savings are substantial. Laser cleaning reduces the need for consumables such as chemicals, abrasives, and mechanical tools, and it minimizes maintenance and downtime by extending the lifespan of equipment and components. The precision and efficiency of laser cleaning also lead to faster cleaning cycles, increasing productivity and reducing operational costs over time.

Laser cleaning is a safer alternative to traditional cleaning methods that involve hazardous chemicals, abrasive materials, or high-pressure equipment. It reduces the risk of worker injury and exposure to toxic substances. Moreover, since laser cleaning is a non-contact process, it minimizes the risk of damage to the components being cleaned. The need for fewer protective measures also simplifies the cleaning process, enhancing workplace safety and reducing health risks for operators.

One of the key advantages of laser cleaning is its versatility. It can be used across a wide range of industries and for a variety of materials, including metals, plastics, ceramics, and composites. Whether it’s removing rust from ship hulls, cleaning delicate semiconductor wafers, or restoring cultural heritage artifacts, laser cleaning can be tailored to suit different surfaces and contamination types. This adaptability makes it an ideal solution for industries with diverse cleaning needs, such as automotive, aerospace, manufacturing, and power generation.

Laser cleaning provides numerous advantages for industrial applications, from its non-abrasive and gentle cleaning to its environmentally friendly and cost-effective nature. It ensures precision, safety, and versatility across a variety of industries, making it a valuable tool for modern manufacturing and maintenance. As industries continue to prioritize efficiency, sustainability, and safety, laser cleaning will remain an indispensable technology for improving processes and reducing operational costs.

While laser cleaning offers many advantages, it is important to acknowledge the challenges and limitations that may affect its application in certain industries. These factors include the cost of equipment, safety concerns, and material compatibility, all of which need to be carefully considered when deciding to implement laser cleaning technology.

One of the primary challenges of laser cleaning is the initial investment required for the equipment. Laser cleaning machines tend to be more expensive than traditional cleaning methods, such as chemical cleaning, abrasive blasting, or mechanical methods. The upfront cost of acquiring laser cleaning technology can be a barrier for smaller companies or industries with tighter budgets. However, it’s essential to note that while the initial costs may be high, the long-term savings from reduced consumables, maintenance, and increased operational efficiency can offset these expenses. Companies must weigh the benefits of long-term cost-effectiveness against the immediate capital investment.

Although laser cleaning is considered a safer alternative to chemical or abrasive cleaning methods, it does come with its own set of safety concerns. The use of high-powered laser beams poses potential risks to operators, including eye damage and skin burns if proper safety measures are not in place. Protective gear such as laser safety goggles and appropriate clothing must be worn during operation to avoid exposure to laser radiation. Additionally, the process can generate fumes and particles, particularly when cleaning painted or coated surfaces, so effective ventilation or fume extraction systems must be implemented to ensure operator safety. Ensuring that operators receive adequate training on the safe use of laser cleaning machines can help mitigate these risks.

Laser cleaning is highly effective for many types of materials, but it does have limitations in terms of material compatibility. While metals such as steel, aluminum, and copper are ideal candidates for laser cleaning, certain materials may not respond well to laser-based cleaning processes. For instance, some plastics, organic materials, or delicate surfaces may absorb the laser energy too efficiently, leading to potential damage or deformation. In cases where the material is highly reflective, such as highly polished metals, it can be more challenging to achieve effective cleaning without adjusting the laser parameters.

Furthermore, laser cleaning may not be suitable for large-scale applications that require deep material removal, such as heavily rusted or corroded surfaces. Traditional methods may still be more practical for such tasks. Therefore, industries must carefully evaluate the types of materials they work with and the nature of the contaminants to determine whether laser cleaning is the most suitable solution.

While laser cleaning offers numerous advantages, it is essential to recognize its challenges and limitations, including the high initial cost of equipment, specific safety concerns, and material compatibility issues. These factors should be considered when determining whether laser cleaning is the right choice for a particular industry or application. By addressing these challenges through proper training, safety protocols, and careful material selection, companies can maximize the benefits of laser cleaning while minimizing potential risks and limitations.

When evaluating the effectiveness of laser cleaning machines in industrial applications, it’s essential to compare them with traditional cleaning methods such as mechanical cleaning, chemical cleaning, and sandblasting. Each method has its advantages and disadvantages, and laser cleaning offers unique benefits that can outperform these conventional approaches in many scenarios.

In comparison, laser cleaning is a non-contact, non-abrasive process that ensures the surface remains intact while achieving precise and consistent results. The laser beam can be controlled to target only the contaminants, leaving the base material undamaged, making it ideal for delicate or high-precision applications.

In contrast, laser cleaning is an environmentally friendly process that eliminates the need for harmful chemicals. It produces minimal waste, and the only byproduct is the vaporized or displaced material from the surface. Additionally, laser cleaning is faster and does not involve the risks associated with chemical exposure, making it a safer and more sustainable option for industrial cleaning.

Laser cleaning, on the other hand, offers highly controlled, selective cleaning, making it ideal for detailed work or areas that require careful attention. Since laser cleaning produces minimal dust and debris, it is a much cleaner process, reducing the need for extensive containment systems and improving overall workplace safety.

While traditional cleaning methods like mechanical cleaning, chemical cleaning, and sandblasting have been widely used across industries, they come with notable limitations in terms of environmental impact, surface damage, and labor efficiency. Laser cleaning stands out as a superior alternative due to its precision, safety, and eco-friendly nature. Its ability to offer consistent, non-abrasive cleaning makes it the preferred choice for many industries seeking advanced surface cleaning solutions.

When implementing laser cleaning in industrial applications, it is essential to understand the technical aspects that influence the process’s effectiveness. This includes selecting the correct laser parameters, considering the material properties of the surface being cleaned, and adhering to safety measures. These factors help optimize the cleaning process and ensure safe operation.

Selecting the appropriate laser parameters ensures precise, efficient cleaning while preserving the integrity of the base material.

Understanding the material properties of the surface being cleaned allows operators to optimize the laser cleaning process for maximum efficiency and effectiveness while minimizing the risk of damage.

By implementing appropriate safety measures, industries can minimize the risks associated with laser cleaning while benefiting from its high precision and efficiency.

Understanding and controlling the technical considerations of laser cleaning—such as laser parameters, material characteristics, and safety protocols—ensures the optimal performance of the cleaning process. By carefully calibrating these factors, industries can achieve precise and efficient cleaning results while maintaining a safe working environment for operators.

Laser cleaning machines have emerged as a powerful solution across various industries, offering an efficient, precise, and environmentally friendly way to remove contaminants such as rust, paint, grease, and other residues. By utilizing advanced laser technology, these machines provide non-abrasive, non-contact cleaning that preserves the integrity of the underlying material, making them ideal for applications in industries such as automotive, aerospace, manufacturing, electronics, and cultural heritage preservation. Compared to traditional cleaning methods like chemical cleaning, mechanical cleaning, and sandblasting, laser cleaning stands out for its precision, reduced environmental impact, and long-term cost-effectiveness. While there are challenges, such as the initial cost of equipment and material compatibility, the advantages of laser cleaning, including its safety, versatility, and ability to handle complex surfaces, make it an indispensable tool in modern industrial processes. As the demand for cleaner, safer, and more efficient cleaning solutions grows, laser cleaning is set to play a crucial role in the future of industrial applications.

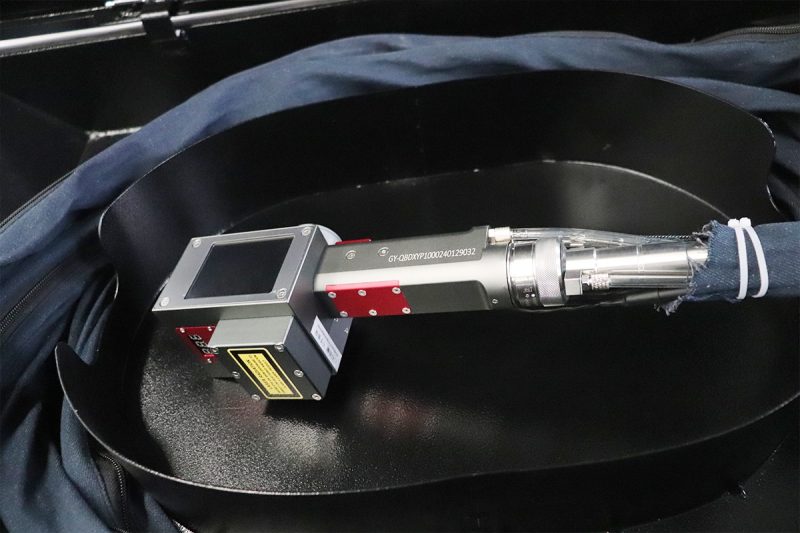

If you’re looking for an efficient, precise, and environmentally friendly way to handle industrial cleaning tasks, AccTek Laser offers cutting-edge laser cleaning solutions tailored to your specific needs. As a professional manufacturer of advanced laser equipment, including laser cutting, welding, marking, and cleaning machines, AccTek Laser provides a range of options that cater to various industries such as automotive, aerospace, electronics, manufacturing, and cultural heritage restoration. Whether you need to remove rust, paint, oxides, or other contaminants, our laser cleaning machines deliver reliable performance while preserving the integrity of the underlying material.

At AccTek Laser, we pride ourselves on offering not only high-performance laser cleaning systems but also comprehensive pre-sales consultation and after-sales technical support to ensure your investment delivers maximum value. Our solutions are designed to improve your cleaning processes while reducing waste, improving safety, and enhancing productivity. Contact AccTek Laser today to learn more about how our laser cleaning solutions can elevate your industrial operations.