What Are the Factors That Affect the Cutting Quality and Precision of Fiber Laser Cutting?

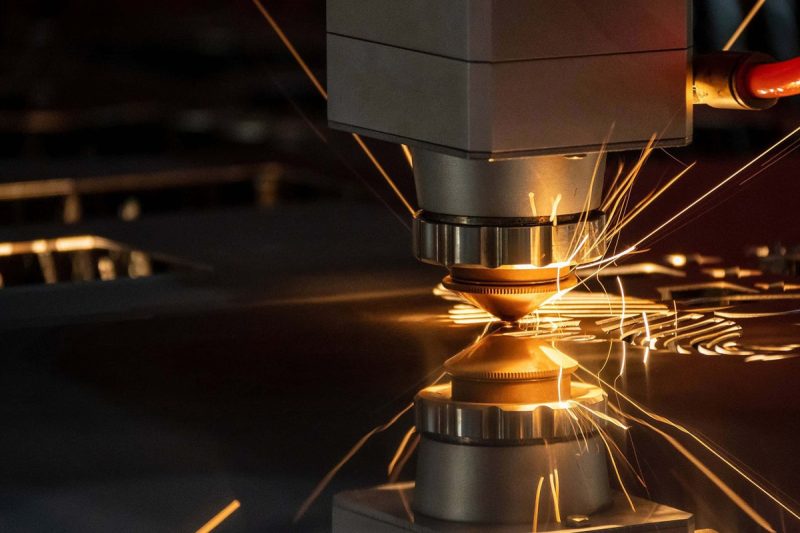

In the field of modern manufacturing and precision machining, fiber laser cutting machines has become the first choice for metal and various materials processing due to its high speed, high precision, and high efficiency. However, to continuously and stably obtain excellent fiber laser cutting quality and cutting accuracy, it is necessary to fully understand the influencing factors and optimize the system. This article will analyze the influencing factors in depth according to the following structure, and propose optimization ideas to help global buyers and laser users improve processing effects, reduce costs, and improve customer satisfaction.

Table of Contents

Material properties

Material properties are the basic elements of fiber laser cutting effects. According to the type, thickness, surface condition of different materials, as well as their reflection and absorption characteristics of laser, corresponding pretreatment and parameter adjustment strategies need to be adopted to ensure cutting quality and cutting accuracy.

Material type and composition

Different materials (such as stainless steel, carbon steel, aluminum alloy, copper, plated plates, etc.) have their own chemical composition and physical properties, which directly affect the interaction between the laser and the material. For example, stainless steel and carbon steel have different laser absorption rates, melting behaviors, and thermal conductivity characteristics; high-reflection and high-thermal conductivity materials such as aluminum alloy and copper are more challenging in absorbing laser energy, and require targeted laser parameters and auxiliary measures.

Thickness and surface condition

Material thickness determines the energy required for penetration and cutting time. Thick plates generally require higher laser power or slower cutting speeds. Surface conditions such as oxide film, oil stains, rust, coating, or sandblasting will affect laser absorption and heat conduction, resulting in fluctuations in cut quality. Therefore, for different thickness ranges, it is necessary to establish a corresponding laser power, cutting speed, and auxiliary gas pressure parameter library; for plates with poor surface conditions, they should be cleaned, rusted, or surface-coated first to improve cutting consistency and edge quality.

Reflectivity and absorption characteristics

The optical properties of the material determine the efficiency of laser energy utilization. Highly reflective materials (such as copper and aluminum) place higher requirements on fiber laser cutting: higher power, special wavelength, or surface pretreatment (such as spraying absorbents, short pulse, or high peak power strategies) may be required. In addition, reflection may pose potential risks to the optical system (reflection damage at the end of the optical fiber), and anti-reflection measures or monitoring devices are required. For highly absorbing materials, laser energy can be used more efficiently, but it is still necessary to prevent excessive melting, slag accumulation, or excessive heat-affected zone.

Fully evaluate and understand the type and composition, thickness, and surface condition of the material to be cut, as well as its reflectivity and absorption characteristics. Through necessary pretreatment (such as cleaning, rust removal, sandblasting, coating treatment, etc.) and targeted laser parameter adjustment, the fiber laser cutting quality and cutting accuracy can be greatly improved, and the defective rate and rework cost can be reduced.

Laser parameters

Laser parameters determine the energy input mode and are the core factors affecting cutting quality and accuracy. It is necessary to scientifically set the power, spot characteristics, pulse or continuous mode parameters according to the material properties and thickness, and ensure the beam quality and output stability.

Power and intensity settings

According to the material type and thickness, the laser power should be reasonably set: insufficient power may not penetrate, and too high power may easily cause excessive melting, widening of the incision, or burning of the edge. At the same time, attention should be paid to the influence of light intensity distribution (Gaussian distribution or flat-top spot, etc.) on the cutting effect: different spot distributions may produce different heat input modes, which need to be selected in equipment configuration or software control.

Beam focus and spot size

The focal position and spot size directly affect the energy density and slit width. A focus that is too deep or too shallow will result in poor penetration or rough edges; a spot that is too large will reduce the energy density and affect the cutting speed and accuracy; a spot that is too small may cause excessive heat concentration and cause slag accumulation. It is necessary to adjust the focal length, focus position, and focusing head parameters through the optical system, and determine the optimal focal position and spot size in combination with actual cutting experiments.

Pulse frequency and duration

For pulsed fiber laser cutting (such as cutting thin plates or special materials), pulse frequency and pulse width affect the instantaneous peak energy and heat-affected zone. High-frequency short pulses help reduce heat input and obtain cleaner edges; low-frequency long pulses can improve cutting penetration, but may increase thermal effects. It is necessary to optimize pulse parameters through experiments in combination with material properties to ensure stable penetration and ideal edge quality.

Beam quality and stability

Beam quality (M2 value) determines the minimum spot size and energy concentration of the laser when it is focused. Excellent beam quality can achieve higher precision cutting and narrower slits; stable laser output avoids fluctuations in cutting quality caused by power fluctuations. The equipment should be equipped with a high-quality fiber laser generator and a real-time power monitoring and feedback system to ensure long-term stability.

By scientifically setting laser power and intensity, optimizing spot size and focal position, adjusting pulse frequency and duration, and ensuring stable beam quality and output, the fiber laser cutting quality and cutting accuracy can be significantly improved, and the trial-and-error cost and scrap rate can be reduced.

Cutting conditions

Cutting conditions directly affect the slag discharge efficiency, kerf formation, and edge quality. The cutting speed, gas type, and parameters need to be set according to the material and laser parameters, and the nozzle position and alignment accuracy should be maintained.

Cutting speed and acceleration

The cutting speed needs to match the laser power and material thickness: too fast a speed may not cut through, too slow a speed may produce too much slag and expand the heat-affected zone. Acceleration affects the quality of the cut at the beginning and end of the cutting, and it is necessary to avoid sudden acceleration and deceleration to cause uneven kerf. The speed curve under different thicknesses and powers can be preset and fine-tuned according to the actual working conditions to achieve the best effect.

Gas pressure and flow

Auxiliary gas is used to purge slag, control oxidation, or protect the cut. The pressure and flow should not hurt the focus of the spot or cutting stability under the premise of sufficient slag purge. It is usually recommended to refer to the equipment manual parameters according to the material thickness and auxiliary gas type, and verify and optimize on-site. Too low gas flow will cause slag residue, and too high gas flow may cause airflow turbulence, resulting in uneven kerf edges.

Nozzle distance and alignment

The distance between the nozzle and the workpiece surface must be kept within the recommended range to ensure that the airflow blows directly to the molten pool without deviating from the spot position; the alignment accuracy determines the consistency of the airflow and the laser focus. Check the nozzle position regularly and consider using an autofocus or visual alignment system to improve consistency and reduce human errors.

Selection and purity of auxiliary gas

Common auxiliary gases include oxygen, nitrogen, argon, etc. Oxygen cutting of carbon steel can increase the cutting speed with the help of oxidation reaction; nitrogen and argon are suitable for stainless steel and aluminum alloys, which can obtain cleaner edges but require higher gas purity. The use of high-purity gas can reduce defects such as oxidation of the cut seam and pores. Foreign trade customers should understand the costs and supply channels of different gases and make reasonable choices based on processing needs.

Optimizing the matching of cutting speed and acceleration, accurately controlling gas pressure and flow, maintaining nozzle distance and alignment, and selecting appropriate and high-purity auxiliary gases can effectively improve the quality and cutting accuracy of fiber laser cutting and reduce defect rates and processing costs.

Machine dynamics and stability

The dynamic performance and stability of the machine are the key to ensuring the accuracy and consistency of the cutting path. Attention should be paid to frame rigidity, motion control, vibration reduction design, and regular calibration and maintenance.

Rigidity and stiffness of machine structure

The machine tool body needs to have a high rigidity design to reduce vibration and deformation during high-speed movement; the structural materials and connection methods must be able to withstand the dynamic loads generated during the processing. The high rigidity foundation stabilizes the cutting path and improves cutting accuracy and repeatability.

Accuracy of the motion control system

Motion elements such as precision guide rails, lead screws or linear motors and servo systems need to have high response speed and positioning accuracy to ensure that the processing path is highly consistent with the CAD/CAM path. Motion errors or delays can cause slit deviations, affecting cutting accuracy and quality.

Vibration reduction mechanism

The application of vibration-absorbing materials in shock-absorbing supports, anti-vibration devices, or structural design can reduce the vibration generated by the external environment or internal movement transmitted to the cutting head. Good vibration reduction design helps stabilize laser focus and maintain cutting-edge consistency, especially when cutting long strokes or complex contours.

Calibration and maintenance procedures

Regularly calibrate and maintain the optical system (such as focusing lens, reflector) and motion system (guide rail lubrication, lead screw inspection); including optical path alignment inspection, laser power calibration, motion accuracy test, etc. Establish daily, weekly, monthly, and quarterly maintenance and calibration plans to detect potential faults promptly and avoid long-term effects of performance degradation on cutting quality and accuracy.

Through high-rigidity body design, precision motion control, effective vibration reduction, and strict calibration and maintenance processes, ensure that the fiber laser cutting equipment operates stably under various working conditions, continuously provides high levels of cutting quality and cutting accuracy, and enhances customer confidence and market competitiveness.

Nozzle design and gas delivery

Nozzle design and gas delivery system have a direct impact on slag discharge and kerf formation, and need to be comprehensively optimized from aspects such as nozzle structure, material, gas type, and flow control.

Nozzle geometry and material

Geometric parameters such as nozzle aperture, cone angle, and length affect the gas flow morphology and impact force; high temperature and corrosion-resistant materials (such as ceramics, stainless steel alloys, etc.) can extend the service life and maintain stable gas flow. Different materials and thicknesses may require different types of nozzle geometries to optimize slag discharge and trimming finish.

Gas type and purity

Auxiliary gas types such as oxygen, nitrogen, and argon need to be selected according to material properties and cutting requirements; high-purity gas can reduce defects such as oxidation and pores, but the cost is higher. For high-end foreign trade customers, gas supply recommendations and cost comparisons need to be provided to guide customers to control costs while ensuring cutting quality.

Alignment and control of gas flow

Ensure that the nozzle center is accurately aligned with the laser focus so that the gas flow can directly purge the molten pool; the gas flow velocity and pressure stability determine the slag purging efficiency. Automatic alignment or visual inspection systems can be used to improve consistency; regularly check the nozzle status, replace or clean it in time to avoid fluctuations in cutting quality due to wear or blockage.

By optimizing the nozzle geometry, selecting durable materials, reasonably selecting high-purity auxiliary gases, and keeping the nozzle aligned with the laser focus and the airflow control stable, the fiber laser cutting quality and cutting accuracy can be significantly improved, defects can be reduced, and the equipment life can be extended.

Environmental factors

The production environment directly affects the equipment performance and the state of optical components. Temperature, humidity, dust, ventilation, etc., need to be controlled to ensure cutting consistency and equipment life.

Temperature and humidity levels

The appropriate workshop temperature ensures that the laser source and optical components work in a stable state; too high a temperature may cause insufficient heat dissipation and laser power fluctuations; too low a temperature may cause static electricity or lubrication problems. Too high humidity can easily cause condensation on the surface of optical components and dampness of electrical components; too low humidity may increase the risk of static electricity. Environmental monitoring and constant temperature and humidity systems should be equipped to keep the temperature and humidity within the recommended range.

Dust and debris pollution

If the smoke and debris generated during the cutting process are deposited on optical lenses, guide rails, or moving parts, it will reduce the laser transmission efficiency, affect the movement accuracy, and aggravate the wear of parts. It is necessary to install a high-efficiency air filtration and dust collection system, and regularly clean the optical and mechanical parts to prevent pollution accumulation.

Air quality and ventilation

A good ventilation system can promptly remove the smoke and harmful gases generated by cutting, protect the health of operators, and avoid corrosion to optical devices.

By controlling the temperature and humidity of the workshop, strengthening dust and debris management, and equipping with efficient ventilation and air filtration systems, the stable operation of the fiber laser cutting equipment can be guaranteed, high cutting quality and accuracy can be maintained, and the equipment life can be extended to enhance customer trust.

Operator skills and experience

The operator is the key executor of fiber laser cutting quality. He needs to have system training, material and parameter knowledge, troubleshooting and optimization capabilities, and continue to learn new technologies.

Laser cutting operation training and proficiency:Establish a complete training system, including safe operation specifications, equipment commissioning, parameter setting process, common fault identification, and handling methods. Skilled operators can quickly locate problems and adjust parameters to reduce production stagnation and scrap. Develop graded training plans for employees with different experience levels, and improve skills through practical exercises.

Knowledge of material properties and cutting parameters

Operators need to understand the chemical composition and physical properties of common materials and their effects on cutting, and master how to set appropriate laser parameters (power, speed, pulse, etc.) in CAD/CAM software and equipment control interface. The combination of material knowledge and parameter library can quickly determine the initial parameters when a new project is started, reducing trial-and-error time.

Ability to troubleshoot and optimize the cutting process

When encountering problems such as cut burrs, slag residue, and uneven edges during cutting, can quickly analyze the causes (parameter mismatch, nozzle problems, environmental changes, etc.) and adjust process parameters or maintain equipment. Operators are encouraged to record failure cases and solutions to form a knowledge base and improve the overall efficiency of the team.

Continuous learning and skills development

Laser cutting technology and material applications are constantly developing. We need to pay attention to new industry trends, new materials, and new equipment functions, and regularly organize technical exchanges or participate in training to improve the team’s technical level. Keep the operation team in the best condition through internal sharing sessions, external training, or cooperation with equipment manufacturers.

By improving the training system, strengthening material and parameter knowledge, improving troubleshooting and optimization capabilities, and encouraging continuous learning, the quality and cutting accuracy of fiber laser cutting can be significantly improved, the team’s ability to cope with complex working conditions can be enhanced, and reliable processing services can be provided to customers.

Design and programming considerations

Good CAD/CAM design and programming are the prerequisites for efficient and high-precision cutting, which requires optimization in software capabilities, nesting layout, compensation settings, and path planning.

CAD/CAM software capabilities

Proficient in using mainstream CAD/CAM software (such as AutoCAD, SolidWorks, and corresponding nesting and post-processing plug-ins) for part modeling and layout. Master the functions of importing multiple file formats, adjusting geometry and curve accuracy, and docking with cutting equipment parameters to ensure that the design results are consistent with the actual cutting of the equipment.

Nesting strategy and part direction

Maximize material utilization and reduce waste by optimizing the nesting strategy; consider material properties and thermal deformation trends when nesting, arrange part directions reasonably, and reduce heat accumulation and deformation risks. Consider the cutting sequence at the same time to reduce thermal effects and deformation.

Slit width compensation

The actual slit width under different materials and laser parameters will vary, and compensation settings need to be made based on experimental data to ensure the dimensional accuracy of the finished product. Establish a parameter database to record the actual slit width under conditions such as material, thickness, speed, and power for quick call-up of subsequent projects.

Path planning algorithm

Optimize the cutting path sequence, reduce empty strokes, round trips and sharp corners, reduce processing time and heat accumulation; reasonably arrange the jump cut and cutting sequence to avoid burrs or warping caused by cutting in unstable areas. For complex contours, apply a smooth transition strategy to ensure path continuity and cutting quality.

By improving the use of CAD/CAM software, optimizing nesting and part direction, accurately setting slit compensation and optimizing path planning, the efficiency and accuracy of fiber laser cutting can be significantly improved, costs can be reduced and customer satisfaction can be improved.

Maintenance and calibration

Regular maintenance and precise calibration ensure that the equipment operates in the best condition for a long time, which is an important part of ensuring cutting quality and accuracy.

Regular maintenance

Includes cleaning of optical components (lenses, lenses, reflectors, etc.), optical path alignment inspection, cooling system maintenance (replacing coolant, checking pumps), mechanical system lubrication and inspection (guide rails, lead screws), and electrical system inspection (cables, sensors). A detailed maintenance list should be formulated to clarify daily, weekly, monthly, and quarterly maintenance items and implementation standards.

Calibration

Involves laser power calibration (verifying output power and setting consistency), focus position calibration (checking focal length accuracy), motion system calibration (detecting positioning accuracy), auxiliary gas system inspection (pressure and flow calibration), and optical alignment (ensuring that the laser beam is transmitted along the correct optical path). Through calibration tools and detection devices, record and adjust errors to ensure that equipment parameters are consistent with software settings.

Maintenance record management

Establish maintenance and calibration logs to record the details of each operation, test results, and treatment measures, so as to facilitate tracing and analyzing trends and prevent potential failures in a timely manner. For foreign trade customers, maintenance guidance manuals and maintenance plan templates can be provided to help customers maintain themselves and reduce the risk of downtime.

Relying on systematic regular maintenance and precise calibration processes, as well as good maintenance record management, it can ensure the long-term stable operation of the equipment, continuously provide high-level fiber laser cutting quality and cutting accuracy, and reduce downtime and maintenance costs.

Quality control and inspection

Establish a sound quality control system, continuously optimize the cutting effect through process monitoring and post-cutting inspection, combined with standards and feedback mechanisms, to meet or exceed customer requirements.

Process monitoring technology

Online visual inspection system, infrared thermal imaging monitoring, laser cutting status monitoring software, etc., can be used to track the molten pool morphology, temperature distribution, and cutting process abnormalities in real time, and timely warn and adjust parameters. Process monitoring helps to reduce scrap rate and improve production efficiency.

Post-cutting inspection method

Includes measuring slit width, verticality detection, surface roughness evaluation, edge chamfering and heat-affected zone detection. Use precision measuring tools (such as calipers, projectors, roughness meters, etc.) and visual inspection to comprehensively evaluate the quality of cut parts.

Standards for evaluating cutting quality and accuracy

Internal inspection standards can be formulated with reference to international or industry standards (such as ISO, ASTM, etc.), combined with customer-specific requirements (tolerances, surface quality, geometric accuracy, etc.). Clearly define the pass and fail standards to facilitate quick judgment and take corrective measures.

Feedback mechanism for process improvement

Associate the test results with parameter settings, equipment status, environmental conditions, operation records, etc., analyze the root causes, and formulate improvement plans. Through regular internal reviews and continuous improvement meetings, feedback the experience to the parameter library, training materials, and maintenance plans to form a closed-loop optimization.

Summary

This article analyzes in depth the various factors that affect the quality and precision of fiber laser cutting section by section: from material properties, laser parameters, cutting conditions, to machine dynamics and stability, nozzle design and gas delivery, environmental factors, operator skills and experience, design and programming considerations, maintenance and calibration, quality control and inspection, etc. Each link needs to be systematically optimized and a standardized process and feedback mechanism established, so that high-quality processing results can be continuously output in different scenarios, meet different customer needs, and enhance competitiveness.

Get Laser Solutions

Our fiber laser cutting system uses high-stability light sources, high-rigidity body structures, precision motion control, and high-quality optical components to continuously output high-quality cutting results under various working conditions. Based on the material type, thickness, and surface condition provided by the customer, the engineering team quickly formulates and adjusts the optimal laser parameters, cutting speed, auxiliary gas scheme, and nozzle configuration through experimental data and advanced simulation tools to ensure the first-time success and maintain stable production. At the same time, we provide workshop environment monitoring and optimization suggestions (such as temperature and humidity, air filtration, and ventilation schemes), and guide the establishment of a complete maintenance and calibration plan to reduce downtime risks and extend equipment life.

In terms of technical services, we provide systematic operator training, covering safe operation, parameter setting, troubleshooting, and process optimization techniques, and support online monitoring or on-site debugging to help customers quickly master and continuously improve the cutting process. The whole process is equipped with a real-time monitoring system and post-processing detection scheme, and a regular review and feedback mechanism is established to convert detection data into optimization suggestions to ensure that the processed parts always meet or exceed industry standards. The global service network can provide remote support, fast spare parts supply, and continuous upgrade guidance, so that customers can obtain excellent fiber laser cutting quality and cutting accuracy in the long term, improve production efficiency, and market competitiveness. If you need a customized solution, please contact the AccTek Laser team to obtain a special plan and quotation.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions