What Safety Precautions Should Be Taken When Laser Marking?

Laser marking is an indispensable technology in modern manufacturing and manufacturing. In this comprehensive guide, we take an in-depth look at a range of safety precautions and measures for safely and effectively performing laser marking tasks.

Energy Consumption And Power Requirements Of CO2 Laser Cutting Machines

This article will focus on the energy consumption and power requirements of CO2 laser-cutting machines. By reasonably controlling cutting parameters, selecting appropriate laser power, and improving energy utilization efficiency, production efficiency can be improved to better meet market demand.

Does The Laser Welding Machine Provide Accurate And Accurate Welding Capacity?

In this article, we will take an in-depth look at the benefits and challenges associated with laser welding technologies, examining their potential to provide precision welds in a variety of industrial applications. Uncover the truth behind laser welding’s touted accuracy and precision with a comprehensive understanding of its capabilities and limitations.

Laser Cutting: Optimized Material Use And Precise Production

In the field of manufacturing and manufacturing, accuracy is very important. In this article, we have deeply studied the world of laser cutting, exploring countless applications, income, and its key role in shaping the future of precise production.

Laser Marking: The Versatile Choice For Small And Large Projects

There may be some differences in the application of various laser markings for projects of different sizes and needs. Can laser marking be used on both small and large projects? Let’s explore it together.

CO2 Laser Cutting Machine Troubleshooting Guide

In this article, we will delve into the common faults of CO2 laser cutting machines and provide effective solutions to help users troubleshoot quickly and accurately when faced with problems, thereby ensuring the continuity of production and stable quality.

Safety Features And Certifications For Laser Welding Machines

Does the laser welding machine have any safety features or certifications? This article will delve into the safety features and certifications of laser welding machines to help readers better understand and deal with related safety challenges.

Laser Cutting Machine Operation Safety Guide

The operation of laser cutting machines involves high-energy laser beams and complex mechanical systems. Safety issues during operations have increasingly attracted people's attention. This article will introduce in detail the various safety measures that should be taken when operating a laser cutting machine to ensure safe operation.

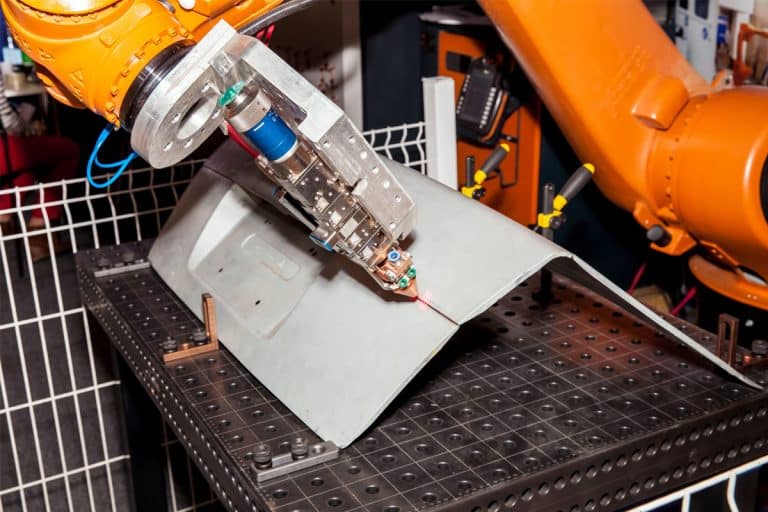

Integration Of Laser Marking Technology And Manufacturing Technology

Combining with other manufacturing processes or technologies has gradually become an important trend in the manufacturing industry. This article will explore the integration of laser marking technology with other manufacturing processes and the benefits this integration brings.

Reliability And Life Management Of Laser Welding Machines

This article will elaborate on many aspects, including evaluating the overall reliability and durability of the laser welding machine, methods to effectively extend the service life of the laser welding machine, etc. Provide readers with a comprehensive guide to the reliability and life management of laser welding machines.

How to ensure consistent welding quality when using laser welding machines?

This article analyzes the key factors affecting the stability of laser welding quality and proposes practical control methods to help enterprises achieve consistent and reliable welding quality.

Optimize Laser Welding Process Parameters for Various Applications

This article examines laser welding parameters and their optimization across various industries, enabling manufacturers to enhance welding quality and production efficiency.

A Comprehensive Guide to Choosing the Right Laser Cutting Machine

This article provides a comprehensive analysis of how to select the most suitable fiber laser cutting machine based on materials, industry, and configuration to improve cutting efficiency, reduce costs, and enable intelligent production for manufacturing enterprises.

How Laser Cutting Improves Overall Efficiency and Productivity in Manufacturing Processes

This article will systematically analyze how laser cutting comprehensively improves the overall efficiency and productivity of manufacturing processes from multiple dimensions, including technology, processes, automation, and quality control.

What Are the Limitations of Laser Cleaning?

This article will systematically analyze the main limitations of laser cleaning from an engineering and application perspective, and provide mature and practical solutions to help manufacturing companies make informed decisions.

What to Consider Before Buying a Laser Cutting Machine

This guide explains how to choose the right laser cutting machine—comparing fiber and CO2 options, key buying factors, and tips for smarter investment.

What Training Is Required for the Safe Operation of a Laser Cleaning Machine?

This article delves into the safety operation training requirements for laser cleaning machines in industrial applications, covering laser safety, protective equipment, equipment maintenance, risk management, and compliance standards.

Optimize Laser Welding Parameters for Different Applications

This article focuses on optimizing laser welding parameters, covering key factors, practical influences, and strategies to improve welding processes across industries.

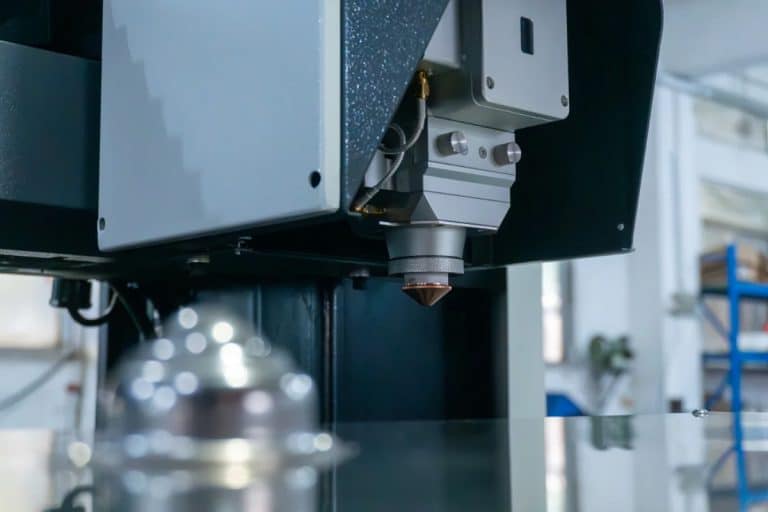

How Does the Focal Length of a Laser Cutting Machine Affect the Cutting Process?

This article primarily discusses the impact of a laser cutting machine’s focal length on cutting quality and efficiency. It analyzes the advantages and disadvantages of different focal lengths, as well as key selection criteria.

Does Laser Welding Require a Welding Mask?

This article mainly introduces the basic concepts of laser welding, potential safety risks, and how to choose and correctly use welding helmets to ensure safe operation.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.