What Are the Limitations of Laser Cleaning?

This article will systematically analyze the main limitations of laser cleaning from an engineering and application perspective, and provide mature and practical solutions to help manufacturing companies make informed decisions.

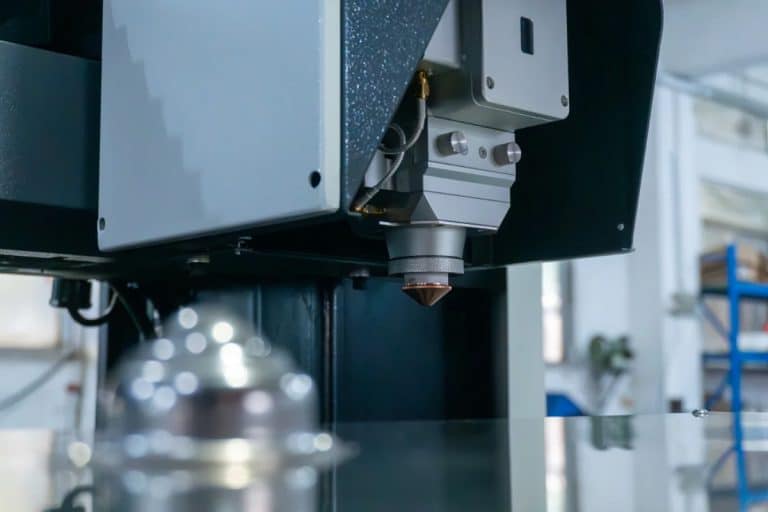

What to Consider Before Buying a Laser Cutting Machine

This guide explains how to choose the right laser cutting machine—comparing fiber and CO2 options, key buying factors, and tips for smarter investment.

What Training Is Required for the Safe Operation of a Laser Cleaning Machine?

This article delves into the safety operation training requirements for laser cleaning machines in industrial applications, covering laser safety, protective equipment, equipment maintenance, risk management, and compliance standards.

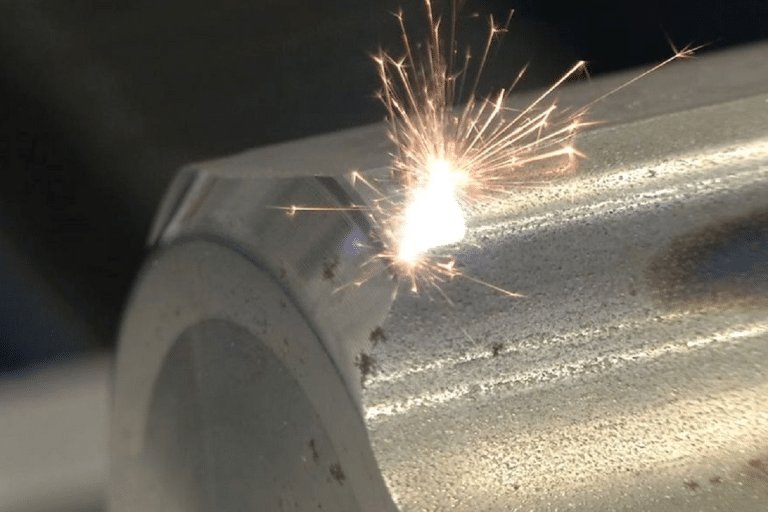

Optimize Laser Welding Parameters for Different Applications

This article focuses on optimizing laser welding parameters, covering key factors, practical influences, and strategies to improve welding processes across industries.

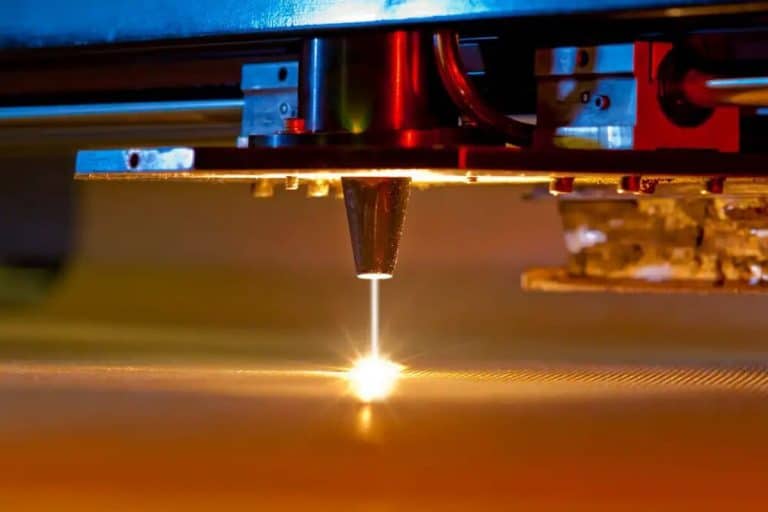

How Does the Focal Length of a Laser Cutting Machine Affect the Cutting Process?

This article primarily discusses the impact of a laser cutting machine’s focal length on cutting quality and efficiency. It analyzes the advantages and disadvantages of different focal lengths, as well as key selection criteria.

Does Laser Welding Require a Welding Mask?

This article mainly introduces the basic concepts of laser welding, potential safety risks, and how to choose and correctly use welding helmets to ensure safe operation.

Motion System in Fiber Laser Cutting Machine

This article mainly introduces four common types of motors in the motion system of fiber laser cutting machines and analyzes their comprehensive impact on cutting accuracy, speed and equipment performance.

How to Control the Quality of Laser Welding

This article systematically analyzes the main challenges of laser welding in terms of thermal management, material reflectivity, and process stability, and provides targeted process and equipment optimization solutions to ensure stable welding quality and improved efficiency.

What Precautions Should Be Taken During Laser Cleaning?

Laser cleaning machines, with their efficient, environmentally friendly, non-contact cleaning methods and comprehensive safety, protection, and maintenance systems, can provide industrial enterprises with high-quality, sustainable surface treatment solutions while ensuring operational safety.

How Does Laser Welding Affect the Heat-Affected Zone (HAZ)?

This article mainly introduces the basic knowledge, significant characteristics and mitigation strategies of the heat-affected zone (HAZ) in laser welding, providing a reference for improving the quality and reliability of welded joints.

What is The Marking Speed of The Laser Marking Machine?

In this article, we delve into the complexities of laser marking machine speed to standard, revealing what it means and the many factors that influence it.

Optimization of Laser Welding Speed And Productivity

Laser welding technology plays an increasingly important role in modern manufacturing. This article will delve into the efficiency of laser welding machines in terms of speed and productivity, and analyze the key factors that affect welding speed and productivity.

The Maximum Cutting Thickness of The CO2 Laser Cutting Machine

The CO2 laser cutting machine offers high precision and versatility. In this article we will examine the factors that influence the maximum cutting thickness of a CO2 laser cutting machine, revealing the interplay between technology, materials, and operating parameters.

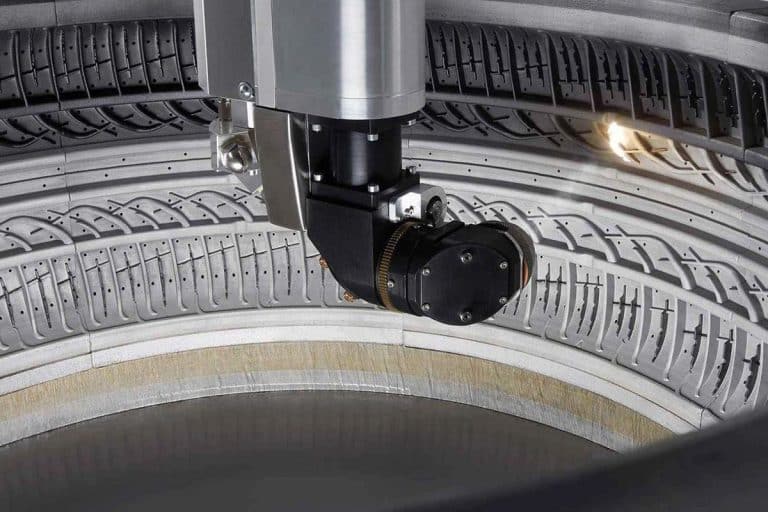

Comprehensive Guide of Laser Cutting: Types, Advantages and Applications of Laser Generator

Laser cutting enables precise cuts in a variety of materials, from metals to composites. In this exploration, we’ll take a closer look at how different types of laser generators work, pinpointing their benefits and applications.

Safety Protection Function of Laser Welding

This article will delve into the types and functions of these safety features and how they can effectively protect operators from potential injuries during the laser welding process and provide reliable protection for laser welding work.

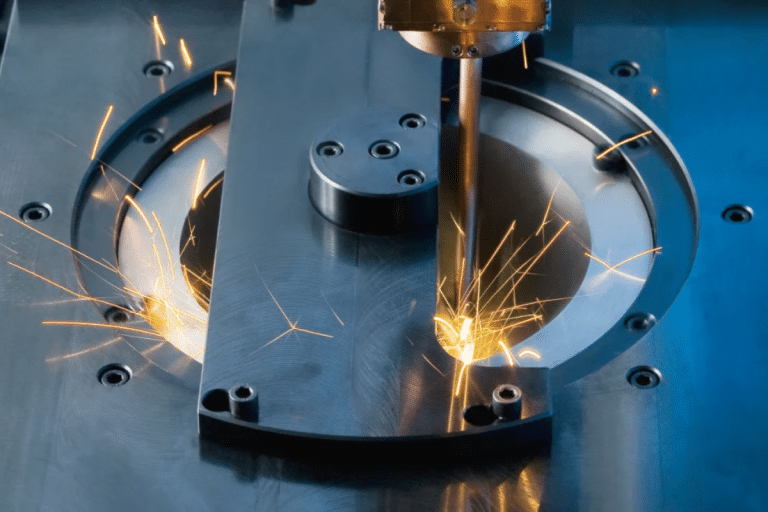

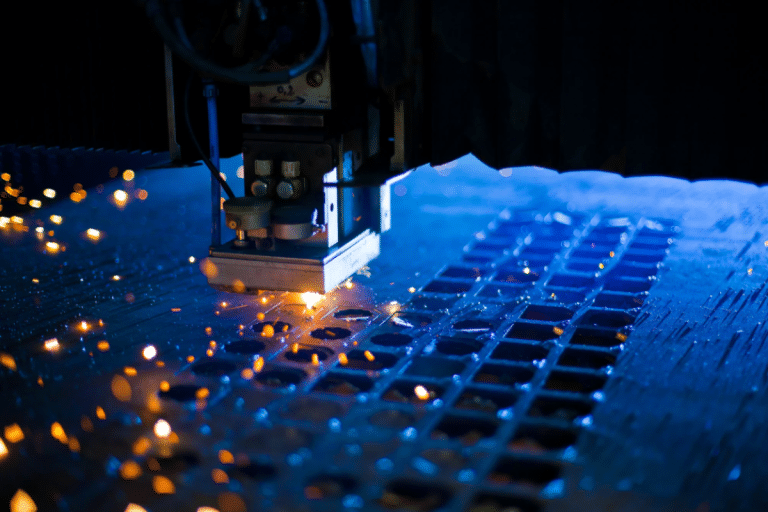

Laser Cutting Technology: Many Advantages For Improving Production Efficiency

This article discusses the advantages of laser cutting in terms of cutting speed, automation integration, accuracy, etc., and explains the far-reaching impact of laser cutting technology on improving manufacturing production efficiency.

What Are The Factors That Affect The Cost of Laser Marking Machine

This article will delve into these factors, including discussing the working principle of laser marking machines, the cost of laser marking machines, and how industry, market, and technology affect laser marking costs.

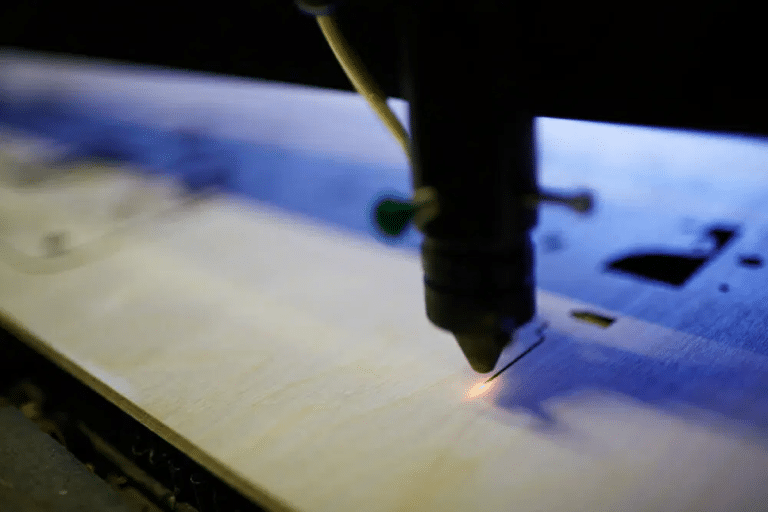

Comprehensive Guide to CO2 Laser Cutting: Materials, Considerations, and Adjustments

This article will take an in-depth look at the materials that can be effectively cut with a CO2 laser cutting machine, including an introduction to how CO2 laser cutting works, some materials that are compatible with CO2 laser cutting.

How to Prevent The Hazards Caused by Laser Welding?

In this article, we will explore the possible hazards of laser welding and how to effectively prevent them to ensure safety and health in the workplace.

What Are The Limitations of Laser Cleaning?

Although laser cleaning technology is a high-tech surface treatment method, it also has limitations that affect its application in specific scenarios. This article will explore the limitations of laser cleaning technology.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.