What Are the Limitations of Laser Cleaning?

This article will systematically analyze the main limitations of laser cleaning from an engineering and application perspective, and provide mature and practical solutions to help manufacturing companies make informed decisions.

What to Consider Before Buying a Laser Cutting Machine

This guide explains how to choose the right laser cutting machine—comparing fiber and CO2 options, key buying factors, and tips for smarter investment.

What Training Is Required for the Safe Operation of a Laser Cleaning Machine?

This article delves into the safety operation training requirements for laser cleaning machines in industrial applications, covering laser safety, protective equipment, equipment maintenance, risk management, and compliance standards.

Optimize Laser Welding Parameters for Different Applications

This article focuses on optimizing laser welding parameters, covering key factors, practical influences, and strategies to improve welding processes across industries.

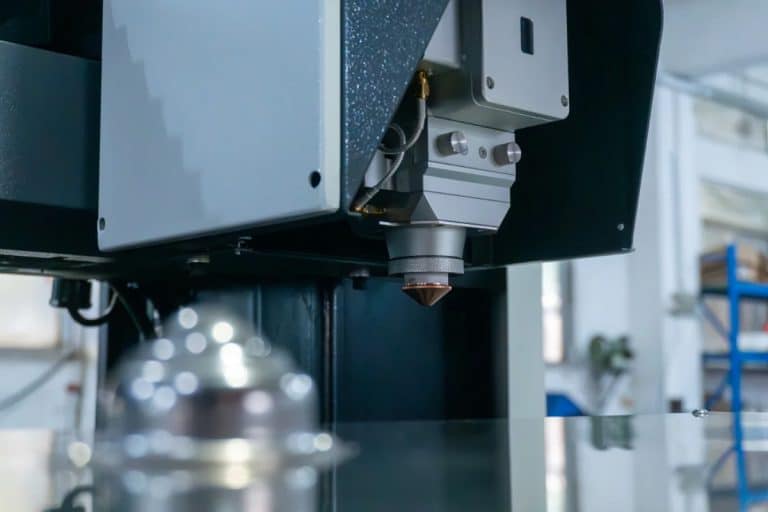

How Does the Focal Length of a Laser Cutting Machine Affect the Cutting Process?

This article primarily discusses the impact of a laser cutting machine’s focal length on cutting quality and efficiency. It analyzes the advantages and disadvantages of different focal lengths, as well as key selection criteria.

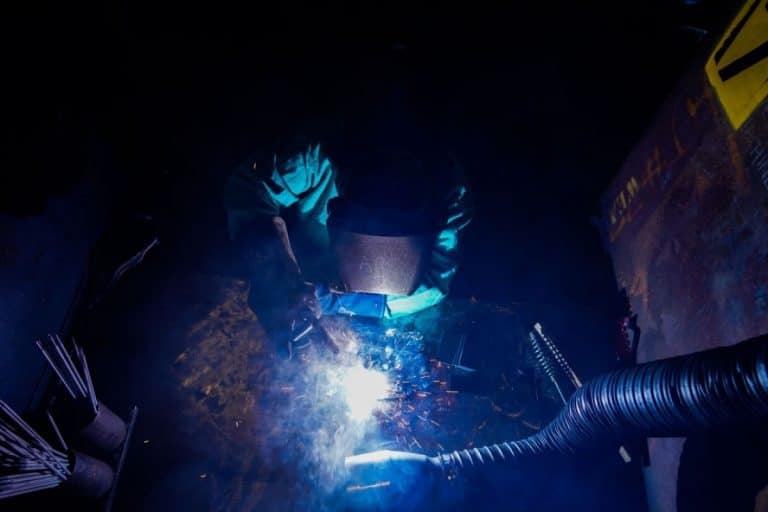

Does Laser Welding Require a Welding Mask?

This article mainly introduces the basic concepts of laser welding, potential safety risks, and how to choose and correctly use welding helmets to ensure safe operation.

Motion System in Fiber Laser Cutting Machine

This article mainly introduces four common types of motors in the motion system of fiber laser cutting machines and analyzes their comprehensive impact on cutting accuracy, speed and equipment performance.

How to Control the Quality of Laser Welding

This article systematically analyzes the main challenges of laser welding in terms of thermal management, material reflectivity, and process stability, and provides targeted process and equipment optimization solutions to ensure stable welding quality and improved efficiency.

What Precautions Should Be Taken During Laser Cleaning?

Laser cleaning machines, with their efficient, environmentally friendly, non-contact cleaning methods and comprehensive safety, protection, and maintenance systems, can provide industrial enterprises with high-quality, sustainable surface treatment solutions while ensuring operational safety.

How Does Laser Welding Affect the Heat-Affected Zone (HAZ)?

This article mainly introduces the basic knowledge, significant characteristics and mitigation strategies of the heat-affected zone (HAZ) in laser welding, providing a reference for improving the quality and reliability of welded joints.

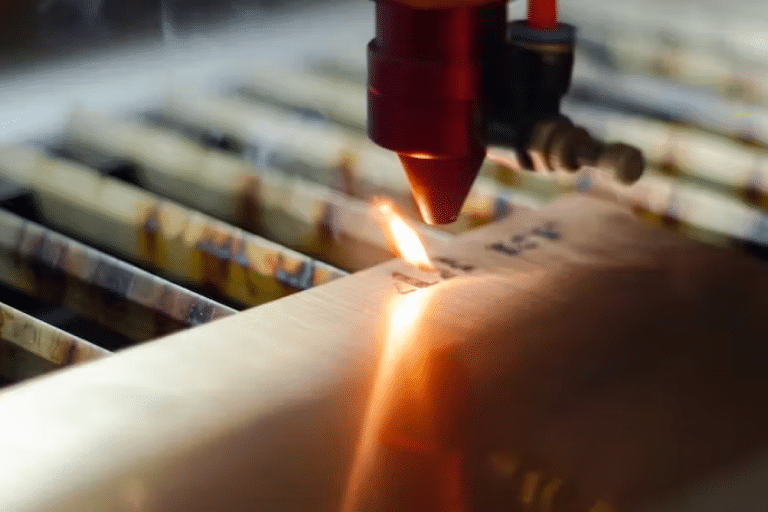

What Plastics Can CO2 Laser Processes?

This article will discuss the plastic materials that CO2 laser marking can process, including explaining the principles of CO2 laser cutting technology, its advantages in plastic processing, the types of plastics that can be marked, different plastic processing applications, and the types of plastics that can meet the standards.

Environmental Advantage: The Sustainability Benefits Of Laser Cutting

This article will introduce the basic principles of laser cutting technology, discuss the importance of laser cutting in environmental protection, analyze the advantages of laser cutting and environmental protection, and look forward to the future development trend of laser cutting.

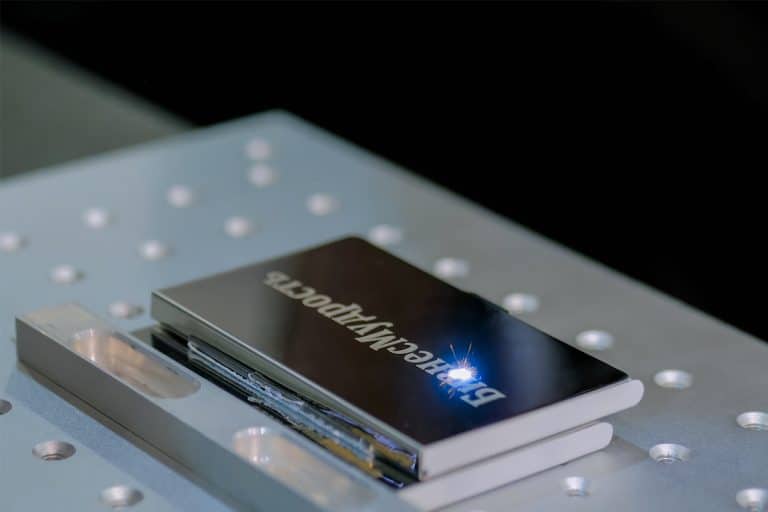

Effect Of Laser Power And Wavelength On Marking Ability

Laser power and wavelength are two key parameters in the laser marking process. We will explore its impact on marking capabilities and provide reference and guidance for the optimization of laser marking processes.

Cooling System And Maintenance Of Laser Welding Machine

This article will introduce the cooling system of the laser welding machine and its principles, the conditions for the effective operation of the cooling system, the importance of maintaining the cooling system, and specific maintenance methods. Protect equipment from overheating damage, ensuring the stability and reliability of your laser welding process.

Factors Affecting Laser Cutting Speed And Efficiency

This article comprehensively explores the factors that influence laser cutting speed and efficiency, enabling users to harness the potential of laser cutting technology to drive innovation in manufacturing processes.

Analysis Of Cost And Influencing Factors Of CO2 Laser Cutting Machine

This article will explore how much a CO2 laser cutter costs, the factors that affect those costs, and compare it to other types of laser cutters. It makes it easy for users to choose the one that best suits their needs.

Maintenance And Repair Requirements For Laser Marking Equipment

With the use of laser equipment, maintenance, and repair have also become important aspects to ensure the operation of the equipment. We will provide a comprehensive introduction to the maintenance and repair requirements of laser marking equipment. To help readers better understand how to effectively manage and maintain these devices.

Power Requirements And Electrical Safety Precautions For Laser Welding Machines

This article will discuss the power requirements and electrical safety precautions of laser welding machines, including understanding the working principle of laser welding machines, the power and voltage requirements of laser welding machines, what electrical safety risks laser welding machines have, and how to avoid them, etc.

Beam Transmission System in CO2 Laser Cutting Machine: Analysis of Principles And Performance Impact

This article will discuss the basic principles of the beam transmission system in CO2 laser cutting machines, performance influencing factors, and how the beam transmission system affects the working performance of CO2 laser cutting machines, and take corresponding optimization measures to improve the application of CO2 laser cutting technology. Levels are of great significance.

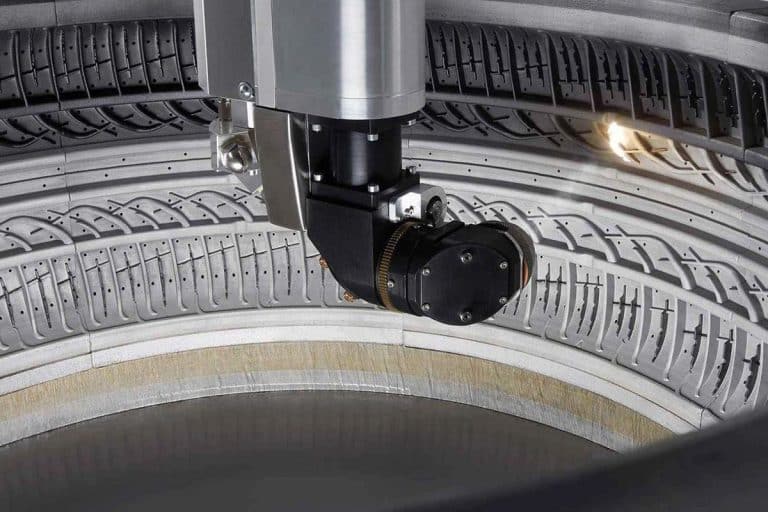

Choosing The Right Laser Cutting Machine For Your Specific Application

It is important to understand the key factors to consider when choosing a laser cutter. In this article, we’ll delve into the importance of each factor and explore how to choose the best laser-cutting machine for your specific application needs.

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.