Pochopení pachů spojených s laserovými řezacími stroji

Laserové řezací stroje, due to their high precision, high efficiency, and high degree of automation, have become indispensable processing equipment in modern manufacturing. They are widely used in a variety of industries, including metal processing, plastic processing, wood cutting, leather engraving, and composite material processing. With the increasing popularity and expanding application of laser cutting machines, people are not only concerned about their cutting accuracy and production efficiency, but also about potential side effects during use: odor and smoke.

During the laser cutting process, the material melts, vaporizes, and even burns under the action of the high-energy laser beam, releasing various gases, particulate matter, and chemical components. When these substances diffuse into the air, they produce pungent or irritating odors. Without proper ventilation and air filtration systems, this not only affects operator comfort and the air quality of the production environment but also poses potential health risks and occupational safety hazards.

Therefore, a deeper understanding of the causes, common types, and impacts of laser cutting odors, as well as exploring how to reduce odors through scientific process adjustments, equipment maintenance, and air purification methods, will not only improve the working environment but also help companies achieve green, environmentally friendly, and sustainable development while maintaining production efficiency.

Obsah

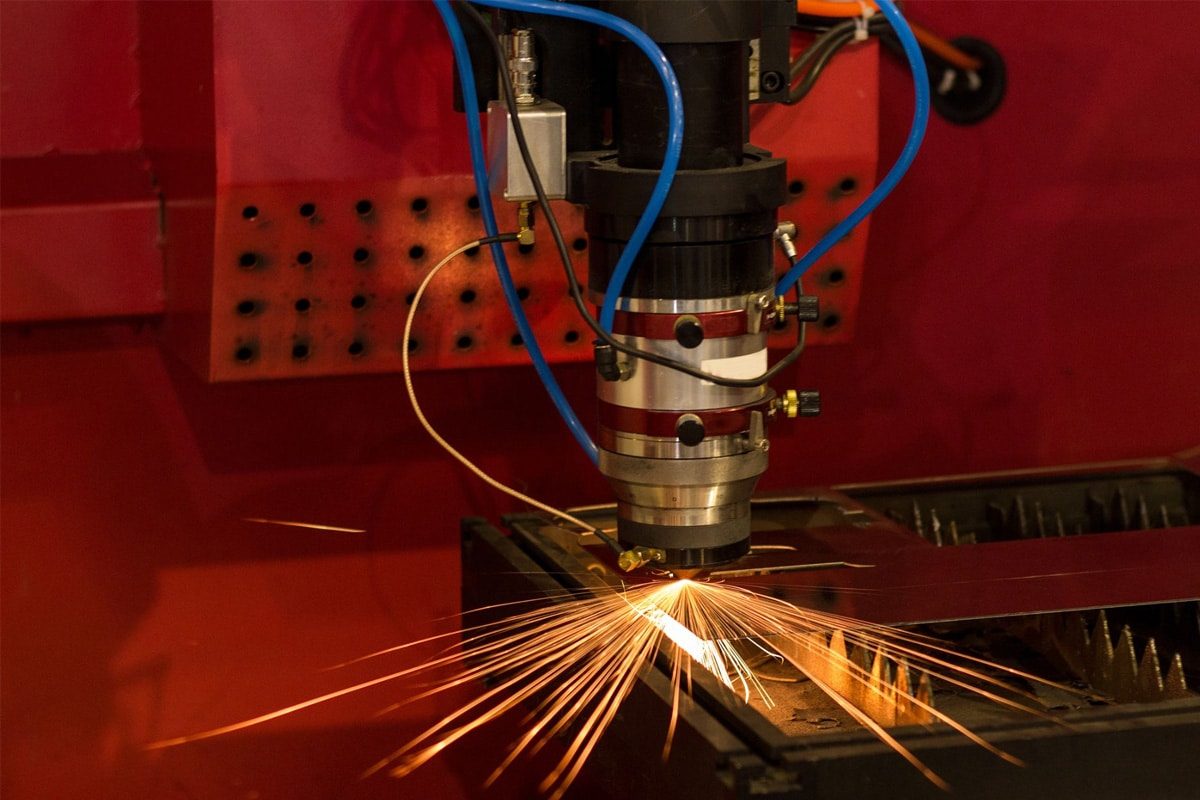

Přehled procesu řezání laserem

The basic principle of a laser cutting machine is to focus a high-energy-density laser beam on the surface of a material. This localized heating causes the material to rapidly melt, vaporize, or burn. High-pressure assist gas then blows away the slag, resulting in precise cutting. This process achieves extremely high cutting speeds and precision, unmatched by traditional mechanical cutting.

In practice, laser cutting machines can process a wide range of materials:

- Metals: These include uhlíková ocel, nerezová ocel, hliník alloys, měď, and their alloys. Cutting these materials is often accompanied by fumes and a slight metallic odor due to metal oxidation or melting.

The physical and chemical properties of different materials determine their reaction to laser light. For example:

- Wood and paper are more likely to produce a burning odor.

- Plastic and plexiglass may emit a pungent chemical odor.

- Although metal materials are less flammable, they can produce metallic fumes and particulate matter at high temperatures.

Therefore, understanding the process principles of laser cutting machines and the properties of common materials not only helps improve cutting quality and production efficiency but also helps operators better understand the sources of odors and fumes during the cutting process, allowing them to take effective measures to ensure a safe and healthy production environment.

Causes of Odor

The generation of odor is almost unavoidable during laser cutting. The root cause lies in the physical and chemical interactions between high-energy lasers and different materials. When materials melt, decompose, or burn at high temperatures, they release a variety of gases, fumes, and particulate matter. These gases permeate the air and create the odors commonly detected by operators. Understanding the source of odors can help better control the air quality of the work environment.

Volatilization and Combustion of Materials

When a laser beam is focused on a material surface, the temperature in that area rises rapidly within a very short period of time. Combustible materials such as wood, paper, and leather will burn directly, producing a typical burning odor. Plastics and plexiglass may release irritating gases due to thermal decomposition. Although metals are difficult to burn, they still undergo oxidation reactions at high temperatures, releasing fumes containing metal particles.

Uvolňování plynů a výparů

During the laser cutting process, some materials release volatile organic compounds (VOCS) and fine particulate matter. These substances not only cause a noticeable pungent odor but can also strain the human respiratory system. For example, the gases released when cutting plastic materials (such as PVC and ABS) are often more irritating and potentially harmful. Without an effective exhaust and filtration system, these gases can accumulate in the workshop air, affecting air quality.

Chemické reakce mezi materiály a laserovou energií

In addition to combustion and vaporization, material components often undergo complex chemical reactions when exposed to laser irradiation. For example, cutting chlorine-containing plastics may release hydrogen chloride gas, which has a distinct pungent odor. Certain metals undergo oxidation reactions at high temperatures, producing gases and particulate matter with a metallic smell. These byproducts not only have varying odors but can also be corrosive or toxic.

In summary, laser cutting odors primarily arise from the thermal decomposition and combustion of materials, the release of VOCS and particulate matter, and complex chemical reactions. Different materials exhibit distinct odor characteristics, ranging from a burnt odor to a pungent chemical odor. Understanding the mechanisms of these odor formations can help companies more effectively formulate production processes and select air purification equipment, effectively reducing the impact of laser cutting odors on operator health and the working environment.

Typy zápachu

During laser cutting, the type and intensity of odors can vary significantly depending on the material properties, cutting parameters, and equipment configuration. Understanding these common odor types not only helps identify substances produced during the cutting process but also allows companies to implement more targeted protective measures in production management to reduce adverse effects on operator health and the working environment.

Burning Odor

When flammable non-metallic materials such as wood, paper, textiles, and leather are exposed to the high temperatures of a laser beam, they carbonize or burn, emitting a distinct burning odor. This odor is generally easy to identify, and its intensity is related to the material’s thickness and moisture content. For example, dry wood is more likely to produce a strong burnt odor when cut, while wood with a higher moisture content may emit a lighter odor.

Chemical Odor

When cutting materials such as plastics, polymethyl methacrylate (PMMA), and rubber, thermal decomposition often releases pungent chemical gases. This laser cutting odor is typically irritating and may even be slightly choking. Different plastics have significantly different odors. For example:

- Cutting PVC may release hydrogen chloride, which is highly irritating.

- Cutting ABS produces fumes with a chemical solvent smell.

- Cutting acrylic is often accompanied by a sweet or pungent organic compound odor.

Smoke and Particle Odors

While most metals don’t produce a noticeable burning odor like wood or plastic during metal cutting, high temperatures can produce metal oxide fumes and fine particles. This metal fume can have a slightly pungent metallic smell, and the particulate matter it contains can affect air quality. Without effective exhaust systems in the workshop, fumes can easily accumulate, causing air pollution and respiratory discomfort.

Factors Affecting Odor Type and Intensity

The odor variations during laser cutting depend not only on the material itself but also on the following factors:

- Material Composition: Organic materials are more likely to emit burnt or chemical odors, while metals primarily emit particulate matter and smoke.

- Material Thickness: Thicker materials remain in the cutting process for a longer period of time, resulting in a stronger odor.

- Cutting power and speed: Excessive laser power or slow cutting speeds can cause excessive material combustion, resulting in a stronger odor.

- Assist gas usage: Different gases, such as oxygen, nitrogen, and air, can affect the degree of combustion and odor composition.

In summary, laser cutting odors can be categorized into three main types: burnt, chemical, and metallic fume particles. Different materials and process parameters directly influence the type and intensity of the odor. Understanding these differentiating characteristics not only helps operators more quickly identify the source of the odor but also guides implementation of effective air purification and safety precautions. This ensures cutting efficiency while creating a healthier and more environmentally friendly production environment.

Otázky zdraví a bezpečnosti

In addition to efficiency and precision, health and safety are also crucial considerations when using laser cutting machines. The fumes, particulate matter, and odors generated during the cutting process often contain hazardous substances, such as volatile organic compounds (VOCS), fine metal particles, and chemical gases. Long-term exposure to these fumes not only affects operator comfort but also poses a potential threat to health. Therefore, companies and operators must pay close attention and implement effective protective measures.

Health Risks

Inhaling untreated laser cutting fumes and odors can cause respiratory irritation, a dry and itchy throat, coughing, headaches, watery eyes, or discomfort in the short term. Long-term exposure without protective measures can lead to more serious consequences:

- Respiratory Diseases: Continuous inhalation of air containing VOCS and particulate matter may increase the risk of chronic bronchitis, asthma, and other conditions.

- Neurological Effects: Some chemical gases may cause dizziness, fatigue, and even impair concentration.

- Occupational Disease Risks: Some studies have shown that workers exposed to laser cutting fumes over a long period of time have significantly higher occupational health risks than the general population.

The Importance of Ventilation and Air Filtration Systems

The key to improving air quality lies in establishing a comprehensive ventilation and air purification system.

- Local exhaust systems: These systems collect and exhaust fumes directly near the pollution source, minimizing their spread.

- Air filtration equipment: High-efficiency filters (such as HEPA or activated carbon filters) effectively remove particulate matter and chemical vapors.

- Whole-site ventilation: Ensures air circulation in the workshop to prevent the prolonged retention of hazardous substances.

Properly designed and maintained ventilation and air filtration systems can significantly reduce the environmental and health impacts of laser cutting fumes.

Comply with occupational health and safety regulations.

Each country has clear regulations regarding air quality and occupational safety in the workplace. For example, both the European Union and the U.S. Occupational Safety and Health Administration (OSHA) have established upper limits for the concentration of hazardous gases and particulate matter. When using laser cutting machines, companies should ensure that their production environments meet relevant standards, conduct regular air quality monitoring, and provide safety training to employees to mitigate potential risks.

Personal Protective Measures

In addition to equipment improvements, operators should also implement appropriate personal protective measures:

- Use a standard protective mask or respirator to effectively filter particulate matter and certain chemical vapors.

- Wear goggles to reduce the risk of eye irritation.

- Maintain good personal hygiene, such as washing hands and face promptly after cutting.

Overall, the smoke and odor generated by laser cutting can have short-term or long-term health effects on operators, necessitating systematic protective measures. Companies should implement efficient ventilation and air purification systems at the equipment level, while strictly complying with occupational health and safety regulations. Operators should also take appropriate personal protective measures to reduce exposure risks. Only by addressing source control, environmental management, and personal protection can we create a safe and healthy working environment while ensuring production efficiency.

Factors Affecting Odor Levels

During laser cutting machine operation, the type and intensity of odors are not fixed but are influenced by a combination of factors. Different operating parameters, material properties, and ventilation and filtration conditions directly determine the severity of odors within the workshop. Understanding these factors can help companies implement more targeted optimization measures in actual production, reducing unnecessary odor disturbances and improving the working environment.

Nastavení a parametry stroje

The operating parameters of a laser cutting machine have a direct impact on odor levels.

- Power: Excessive power can cause excessive material combustion, producing stronger burnt and chemical odors. Excessive power can lead to incomplete cutting, prolonged processing time, and increased smoke production.

- Cutting Speed: Too slow a cutting speed exposes the material to high temperatures for extended periods, releasing more smoke and particulate matter. Too fast a cutting speed can result in a less clean cut, but the odor is relatively mild.

- Auxiliary Gas Types: Commonly used are oxygen, nitrogen, and compressed air. Oxygen cutting tends to intensify combustion and increase odor intensity; nitrogen suppresses combustion, reducing smoke and odor. Air cutting offers a moderate balance between cost and performance. Properly selecting an assist gas can effectively improve odor issues.

Materiálové vlastnosti

The chemical composition, thickness, and surface coating of the material itself are key factors in determining the type and intensity of odor.

- Chemical Composition: Polymer materials such as plastics, rubber, and plexiglass are more likely to release volatile organic compounds (VOCS) with pungent odors; metal materials, on the other hand, produce particulate matter and metallic fumes.

- Thickness: Thicker materials require longer cutting times, resulting in more intense combustion and decomposition, and a stronger odor.

- Surface Coating: Some metals or wood surfaces are coated with paint, glue, or protective coatings. These substances often produce strong chemical odors when exposed to high temperatures, significantly impacting air quality.

Exhaust and Filtration System Efficiency

Even though odors are unavoidable during the cutting process, the efficiency of the exhaust and filtration systems will determine the air quality within the workshop.

- Exhaust System: Efficient local exhaust devices can extract smoke directly near the pollution source to prevent its spread.

- Air Filtration Equipment: Equipped with high-performance filters (such as HEPA and activated carbon filters) to effectively remove fine particulate matter and harmful gases.

- System Maintenance: If equipment is not cleaned for a long time or the filter element is clogged, efficiency will be significantly reduced, causing odor accumulation in the workshop and deteriorating air quality.

Overall, the intensity of laser cutting odors is primarily affected by three factors: machine parameter settings, material properties, and the efficiency of the exhaust filtration system. By properly adjusting laser power and speed, selecting appropriate assist gases, optimizing material selection, and maintaining an efficient filtration system, companies can significantly reduce odor levels while maintaining cutting efficiency, creating a healthier and safer production environment.

Tips for Reducing Odor

Although laser cutting machines inevitably produce odor and smoke during processing, through scientific management and optimization, the impact of odor can be significantly reduced while maintaining cutting efficiency. For companies seeking to improve their work environment and enhance production quality, the following tips are important for reducing laser cutting odor.

Equipment Maintenance and Cleaning

Maintaining the laser cutting machine in good operating condition is the primary measure for reducing odor.

- Optical System Maintenance: Regularly clean the laser head, reflector, and lens to prevent energy loss due to beam scattering and reduce excessive material burns.

- Exhaust Duct Cleaning: After long-term use, smoke and particulate matter easily accumulate in the exhaust ducts and filters, reducing exhaust efficiency and leading to odor accumulation. Regularly cleaning or replacing filter elements can maintain efficient exhaust system operation.

- Overall Maintenance: Regularly check the laser cutting machine’s seals and vents to ensure smoke does not backflow into the workshop.

Optimizing Cutting Parameters

Properly setting cutting parameters can reduce smoke and odor generation at the source.

- Power Adjustment: Avoid excessive power, which can cause intense material combustion and produce burnt or chemical odors. Also, avoid insufficient power, which can lead to prolonged cutting times and increased smoke accumulation.

- Speed Optimization: Select an appropriate cutting speed to achieve optimal material separation and minimize unnecessary thermal decomposition.

- Assist Gas Selection: Where conditions permit, nitrogen is preferred for cutting to minimize combustion reactions. While oxygen offers high cutting efficiency, it also produces a stronger odor.

Proper Waste Disposal

Residues and waste generated during the cutting process, if left in the workshop for extended periods, will continue to emit odors and even become a source of air pollution.

- Classified Collection: Separate waste materials by material type to avoid mixing different materials and generating new odors.

- Timely Cleanup: Establish a comprehensive cleanup system to ensure that cutting waste is disposed of promptly.

- Environmentally Friendly Disposal: Choose compliant recycling or disposal methods to minimize secondary pollution and enhance your company’s environmental image.

In summary, the key to reducing odor from laser cutting machines lies in equipment maintenance, optimized cutting parameters, and waste management. By regularly cleaning equipment, rationally adjusting power and speed, and promptly disposing of waste, companies can effectively reduce the impact of smoke and odor on operators while also improving workshop air quality and overall production efficiency. These measures not only contribute to a better working environment but also provide a crucial foundation for achieving green production and sustainable development.

souhrn

Laser cutting machines, with their high precision, high efficiency, and automation advantages, have become essential equipment in industries such as metalworking, plastics processing, and wood cutting. However, while improving productivity and cutting accuracy, the cutting process inevitably generates odor and smoke. If these smoke and volatile organic compounds (VOCS) are not effectively controlled, they not only affect operator comfort but also pose health risks and negatively impact the air quality of the working environment. By scientifically optimizing cutting process parameters, properly adjusting laser power and cutting speed, integrating efficient fume exhaust and air filtration systems, strengthening equipment maintenance, and strictly adhering to occupational health and safety regulations, companies can significantly reduce the impact of laser cutting odors on the environment and personnel health, while ensuring long-term stable operation and improved production efficiency.

As a professional laser solutions provider, AccTek Laser is committed to providing global customers with high-performance, highly reliable laser cutting machines and accompanying advanced fume exhaust and air filtration systems, helping companies achieve efficient processing while reducing odor and harmful substances generated during processing. Our equipment is suitable for a variety of materials, including metal, plastic, and wood, meeting diverse processing needs. Through comprehensive after-sales technical support and customized solutions, we ensure businesses create a safe, environmentally friendly, and sustainable production environment. Choosing AccTek Laser not only improves production efficiency but also enhances the working environment, achieving high-quality, environmentally friendly laser cutting production.

Kontaktní informace

- [email protected]

- [email protected]

- +86-19963414011

- č. 3 zóna A, průmyslová zóna Lunzhen, město Yucheng, provincie Shandong.

Získejte laserová řešení