What Environmental Considerations Should Be Taken When Using Laser Welding Machines?

In today’s world, where sustainable development is receiving increasing attention globally, the manufacturing industry is also facing higher environmental requirements. Laser welding technology, with its efficiency, precision, and high level of automation, is widely applied in industries such as automotive manufacturing, electronics, appliances, and metal processing. However, while enjoying the convenience brought by advanced technology, we must also be aware of the potential environmental impacts during the laser welding process and take scientific and reasonable measures to reduce pollution, improve energy efficiency, and achieve green production.

Obsah

Understanding Laser Welding Machines

As the manufacturing industry continues to demand higher precision, efficiency, and environmental standards in welding, laser welding technology, as an advanced high-energy beam welding process, is being increasingly adopted across various industries. Compared to traditional welding methods, laser welding offers significant advantages such as low heat input, narrow weld seams, high speed, and strong adaptability. To meet different process requirements, various types of laser welding machines have emerged, with fiber laser welding machines being the most mainstream and efficient. Understanding the types and principles of laser welding machines helps businesses make more informed and rational decisions when selecting equipment.

Pracovní princip

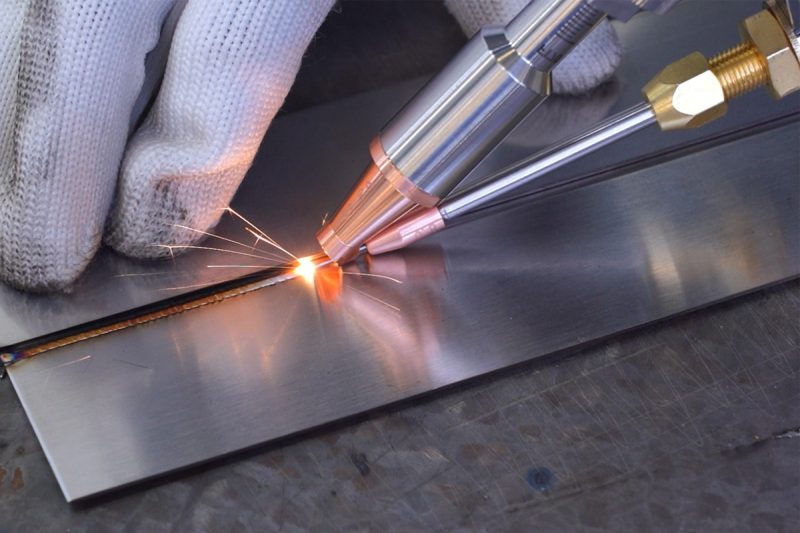

Laser welding works by focusing a high-energy-density laser beam on the workpiece joint, causing localized material to heat up and melt. After cooling, a strong weld seam is formed. The entire process is a non-contact method, which results in a small heat-affected zone, fast welding speed, and high weld quality. It is particularly suitable for welding precision components and high-end industrial products.

Types of Laser Welding Machines

Laser welding machines are mainly classified into the following types based on the laser source and application scenarios:

Vláknový laserový svařovací stroj

The fiber laser welding machine uses a fiber laser generator as the core laser source and transmits the laser beam efficiently to the welding head through flexible optical fibers. It offers extremely high optical-to-electric conversion efficiency (up to 40%), with concentrated energy and strong penetration. It is suitable for high-strength welding of various metal materials, such as stainless steel, carbon steel, aluminum alloys, copper, etc.

Main Advantages:

- High energy efficiency, low operating costs: High optical-to-electric conversion rate reduces electricity consumption.

- Stable weld quality: Deep welds, narrow seams, and small heat-affected zones, eliminating the need for post-weld grinding.

- Strong adaptability: Suitable for spot welding, seam welding, stack welding, and butt welding, ideal for connecting complex structures.

- Low maintenance cost: No easily worn optical components, virtually maintenance-free.

- Easy automation integration: Widely used in robotic laser welding systems, improving the automation level of production lines.

- Suitable for long-distance transmission: Fiber transmission is flexible, adapting to various industrial environments.

Svařovací stroj CO2 laser

The CO2 laser welding machine uses CO2 gas as the working medium, suitable for welding both metals and non-metals, especially ideal for welding materials like plastic, acrylic, and organic glass. Although it offers higher power, its system is bulky and has a low optical-to-electric conversion efficiency.

Semiconductor Laser Welding Machine

This welding machine is compact and small in size, mainly used for micro-welding applications such as electronic components, battery tabs, and medical devices. It is suitable for welding parts that require high precision and minimal heat input.

Applications of Laser Welding in Various Industries

- Automotive Manufacturing: Precision welding of high-strength steel and aluminum alloys.

- Electronics Industry: Micro-welding of precision components.

- Medical Devices: High-purity welding of stainless steel and titanium alloys.

- Metal Processing: Efficient connection of various structural parts, decorative components, and hardware.

The choice of laser welding machine directly impacts product quality, production efficiency, and cost control. Among various welding equipment, fiber laser welding machines have become the core welding tool in modern metal manufacturing due to their high energy efficiency, low maintenance, and excellent welding performance. Different types of laser welding machines have their own characteristics, making them suitable for different materials and process scenarios. In practical applications, companies should choose the most suitable equipment based on their needs, processing objects, and production capacity to maximize the value of the welding process.

Environmental Issues of Laser Welding

Although laser welding technology is considered a cleaner and more efficient processing method, especially in reducing welding spatter and lowering pollutant emissions compared to traditional welding, it still has certain environmental impacts during actual operation. In industrial mass welding applications, if proper environmental control measures are not in place, harmful gases, hazardous waste, and high energy consumption issues may arise. The following focuses on the environmental impact of fiber laser welding machines.

Emission of Smoke and Gases

Fiber laser welding machines use high-energy density laser beams for deep fusion welding. During the welding process, the laser rapidly melts the metal material, causing some of it to evaporate and form metal fumes and gases. When the welded material contains oil, coatings, or special alloys, ozone, volatile organic compounds (VOCs), and fine particulate matter (PM) may be released, potentially harming the respiratory system of operators and polluting the surrounding air.

In addition, if welding is carried out in a confined space for extended periods without timely removal of welding fumes, these fumes may corrode the equipment structure, affecting its lifespan. Therefore, the installation of an efficient laser smoke purification system and localized exhaust system is essential to protect the production environment and personnel health.

Vznik nebezpečného odpadu

Although the fiber laser welding process itself does not involve traditional consumables such as flux or welding rods, over long-term operation and maintenance, a series of indirect waste materials may still be generated, including:

- Replaced laser protective lenses or protective covers

- Contaminated cooling liquids or lubricants

- Filter cotton and filter elements containing metal particles

- Discarded cleaning cloths used for wiping welds

These wastes typically contain heavy metal residues or chemicals and are classified as hazardous industrial waste. They must be strictly collected, classified, and disposed of according to environmental regulations to prevent soil and water contamination.

Spotřeba energie a účinnost

Vláknové laserové svařovací stroje have an extremely high electro-optical conversion efficiency, typically reaching over 35%, far exceeding that of CO2 laser welding machines (which are usually below 15%). This means that fiber laser equipment consumes less energy for the same welding tasks, making it more conducive to achieving green production goals.

However, if the equipment parameters are improperly configured (e.g., laser power set too high or welding speed incorrectly adjusted), or if the cooling system operates under high load for extended periods, unnecessary energy waste may occur. Therefore, companies should focus on providing professional training for operators and planning the processing technology to ensure an efficient and low-energy consumption welding process.

Although fiber laser welding technology offers more environmental advantages than traditional welding, attention should still be paid to the issues of gas emissions, waste management, and energy usage during actual production. By equipping advanced dust filtration equipment, implementing hazardous waste disposal regulations, optimizing process parameters, and improving energy efficiency management, companies can not only reduce environmental risks but also enhance sustainability. Choosing fiber laser welding equipment with excellent environmental performance will be an important step in promoting green manufacturing and achieving carbon reduction goals.

Environmental Protection Considerations

In the context of promoting green manufacturing and sustainable development, companies must prioritize environmental protection when using laser welding equipment, especially fiber laser welding machines. By scientifically configuring environmental protection facilities, improving operational standards, and regulating waste disposal processes, companies can not only effectively reduce pollution to air, water, and soil but also enhance their corporate image and strengthen their competitive compliance in international markets. Below are several key environmental measures to consider during the operation of laser welding equipment.

Install Efficient Ventilation and Fume Extraction Systems

The metal particles, harmful gases, and ozone released during the laser welding process pose potential threats to air quality and operator health. In enclosed workshops, pollutant concentrations are more likely to accumulate. Companies should equip welding areas with efficient laser fume extraction systems, preferably smoke collectors with HEPA (High-Efficiency Particulate Air) filters and activated carbon filters to ensure that over 99.9% of particulate matter and gaseous pollutants are effectively filtered. Additionally, setting up local exhaust systems and proper airflow channels helps intercept pollutants at the source, preventing them from spreading throughout the workshop and improving overall air circulation efficiency.

Hazardous Waste Management

Although fiber laser welding processes do not rely on large amounts of chemical additives, unavoidable hazardous waste still accumulates over time, such as:

- Contaminated cleaning cloths, filters, and lubricant containers

- Replaced laser lenses, protective goggles, and cooling liquid residues

- Metal residues generated during stirring or recycling processes

Companies should establish standardized hazardous waste collection, classification, and storage mechanisms, use containers with anti-leak features for waste collection, and regularly entrust qualified environmental service providers to recycle or harmlessly dispose of the waste, preventing illegal dumping or incineration that could cause irreversible environmental damage.

Improving Energy Efficiency

Fiber laser welding machines have a natural advantage in energy efficiency due to their excellent photoelectric conversion rate (≥35%) and low energy consumption. Companies should prioritize selecting laser equipment with energy efficiency certifications and reasonably configure power output, focusing speed, and welding paths based on processing task characteristics, optimizing energy use from the source.

Additionally, by deploying intelligent control systems, energy consumption can be monitored in real-time, further improving the equipment’s uptime and energy efficiency. Reasonably scheduling production shifts and controlling equipment start/stop times can also reduce overall carbon emissions without affecting production capacity.

Material Selection and Recycling

Material selection not only impacts welding efficiency but also plays a role in the environmental performance of the welding process. Recyclable, biodegradable, or non-harmful materials, such as food-grade stainless steel and aerospace aluminum alloys, should be prioritized, while avoiding materials coated with lead, chromium, or other heavy metals to reduce the production of toxic volatile substances during welding.

For metal waste such as offcuts and scraps produced during welding, companies should establish a classification, recycling, and reuse system. This not only helps reduce material waste but also improves resource utilization and lowers procurement costs.

Training and Safety Protocols

Environmental protection depends not only on equipment but also on the people operating it. Companies should regularly conduct training for laser welding operators on environmental protection, safety, and emergency handling, ensuring that every employee understands the operational standards for welding equipment, the potential risks of environmental pollution, and personal protection measures.

Standard operating procedures should clearly define the requirement to wear protective gear such as safety glasses, face shields, respirators, and work uniforms, and regular safety checks of equipment and smoke collection systems should be performed to reduce the likelihood of accidents and occupational diseases.

Compliance with Regulations and Standards

To achieve compliance and standardized operations, companies must strictly adhere to local and export market environmental protection regulations and safety standards, such as:

- ISO 14001 (Environmental Management System)

- OSHA (Occupational Safety and Health Management Standards)

- CE Certification (EU Market Access)

- RoHS Directive (Restriction of Hazardous Substances in Electrical and Electronic Equipment)

Regular environmental audits and continuous optimization of the environmental management system help enhance the company’s international reputation and improve the chances of collaborating with high-end clients from Europe and the United States.

Environmental protection is no longer a choice; it is a crucial responsibility that companies must bear in laser welding applications. By adopting efficient and energy-saving equipment like fiber laser welding machines and implementing scientific measures such as smoke extraction systems, waste management, material recycling, and operator training, companies can not only reduce their ecological impact but also ensure that they achieve green manufacturing and establish a sustainable brand image. In the future, environmental compliance will not only be about cost control and efficiency optimization but also about gaining the trust of global customers and securing orders as a core competitive advantage.

Shrnout

Laser welding technology, as an essential tool in modern manufacturing, not only offers high efficiency and superior quality but also has significant potential in environmental protection. By carefully selecting equipment, implementing comprehensive environmental measures, and strictly adhering to operating standards, we can fully achieve a green, low-carbon, and safe laser welding production process.

Na AccTek Laser, we are committed to the product philosophy of “high performance + environmentally friendly manufacturing.” We offer a range of energy-efficient and high-performance fiber laser welding solutions, widely applied in the green welding practices of industrial customers worldwide. If you are interested in environmentally friendly laser welding equipment, feel free to contact our professional team for customized recommendations and sample testing support.

Kontaktní informace

- [email protected]

- [email protected]

- +86-19963414011

- č. 3 zóna A, průmyslová zóna Lunzhen, město Yucheng, provincie Shandong.

Získejte laserová řešení