Jaké školení je nutné pro bezpečný provoz laserového čisticího stroje?

In recent years, laser cleaning technology has rapidly gained popularity across various industries, including manufacturing, mold maintenance, cultural heritage restoration, and the automotive and aerospace sectors. Compared with traditional cleaning methods such as chemical cleaning, sandblasting, or ultrasonic cleaning, laser cleaning offers significant advantages—high efficiency, precision, non-contact operation, and environmental friendliness. By directing a high-energy laser beam onto the surface of a material, it instantly vaporizes or removes contaminants, rust, or coatings without damaging the substrate. This eco-friendly and precise surface treatment method is gradually replacing conventional techniques and becoming an essential solution in global industrial maintenance and surface preparation.

However, while a laserový čisticí stroj delivers impressive performance and sustainability benefits, it is still a high-energy industrial device that requires strict safety measures during operation. The laser beam itself poses potential hazards such as eye injuries, skin burns, electrical accidents, or even fire risks if mishandled. In addition, improper operation or maintenance can lead to optical contamination, lens damage, and inconsistent cleaning quality—ultimately affecting productivity. Therefore, before integrating laser cleaning equipment into production, companies must establish a comprehensive safety training program to ensure that every operator understands laser safety principles, equipment handling skills, and risk management procedures. Only through proper training can businesses fully leverage the advantages of laser cleaning while maintaining a safe and efficient working environment.

Obsah

Understanding Laser Cleaning Technology

Laser cleaning is an advanced surface treatment technology based on the principle of light-matter interaction. When a high-energy-density laser beam irradiates the surface of a workpiece, surface contaminants, oxide layers, or coatings rapidly absorb energy, undergoing thermal expansion, vaporization, or peeling, thus achieving a highly efficient and precise cleaning effect. Compared with traditional chemical cleaning or mechanical grinding, laser cleaning is non-contact, solvent-free, and produces no secondary pollution, meeting the requirements of modern industry for green manufacturing and sustainable development. Furthermore, laser cleaning can handle complex shapes or hard-to-reach workpiece surfaces with virtually no mechanical damage to the material itself, exhibiting unique advantages of high precision, high efficiency, and controllability.

Before actual operation, operators must thoroughly understand the basic principles of laser cleaning and the material response characteristics, and master the interaction laws between the laser and different workpiece surfaces. Only by fully understanding these scientific principles can reasonable judgments be made in setting equipment power, selecting spot size, and adjusting scanning speed, thereby ensuring a safe, stable, and efficient cleaning process. At the same time, understanding the application scope, applicable materials, and potential limitations of laser cleaning helps operators to develop optimal solutions for different workpieces and production environments, improve production efficiency and processing quality, and effectively prevent equipment damage or safety accidents caused by misoperation, thus providing a guarantee for enterprises to achieve green, efficient, and sustainable production.

Technical Principles and Types

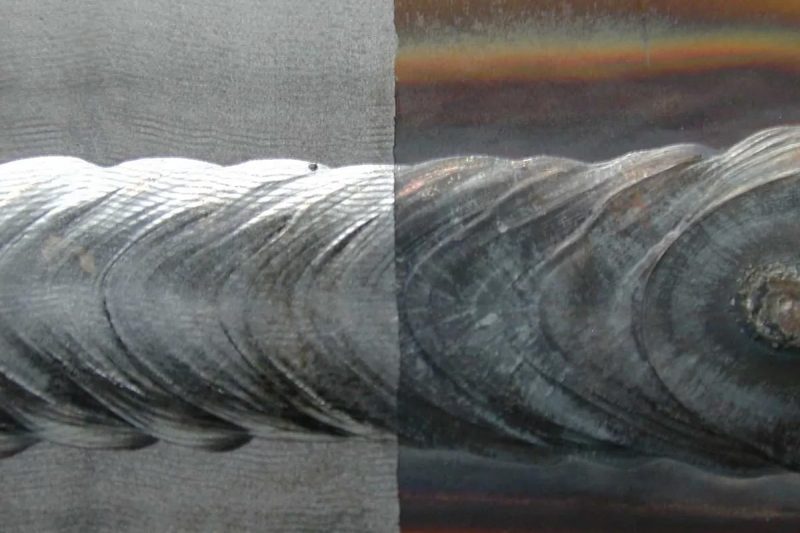

Laser cleaning technology is an advanced process that relies on the interaction between light and matter to achieve surface cleaning and treatment. Depending on the laser output mode, laser cleaning technology is mainly divided into pulsed laser cleaning and continuous laser cleaning, each with distinct operating principles and application scenarios. Pulzní laserové čisticí stroje emit short, high-peak-power laser pulses that act instantaneously on the surface layer, causing the contaminants to absorb energy and rapidly vaporize or generate micro-explosions that lift off surface impurities, oxide layers, or coatings. This method produces minimal heat-affected zones and offers high precision, making it ideal for delicate applications such as precision molds, cultural heritage restoration, electronic components, and high-end parts. It effectively prevents damage to the substrate while ensuring uniform and consistent cleaning results.

Kontinuální laserové čisticí stroje employ a steady and continuous laser beam to clean large-area workpieces, capable of removing contaminants and coatings over a wide surface quickly, making them suitable for industrial applications such as rust removal from steel structures, pre-weld surface preparation, and paint or coating stripping. The advantage of continuous laser cleaning lies in its high cleaning speed and efficiency, which can significantly shorten production cycles in industrial settings. However, the heat-affected zone is relatively larger, making it more suitable for large-scale, heavy-duty industrial operations rather than applications requiring extremely high precision. Operators must carefully adjust laser power, spot size, scanning speed, and focal length according to material properties and cleaning requirements to achieve optimal cleaning results while avoiding substrate damage.

In addition, operators should gain a thorough understanding of how various laser parameters affect cleaning performance. Factors such as wavelength, power, frequency, pulse width, and focal length directly influence cleaning efficiency and substrate protection. Short-wavelength lasers are most effective for removing metallic oxides, while mid-infrared lasers perform better for eliminating organic contaminants. Mastering these technical principles enables operators to select the most appropriate cleaning parameters according to different materials, contaminant types, and working conditions, thereby enhancing cleaning quality, reducing material waste, and ensuring the safe and stable operation of the equipment.

Aplikace laserového čištění

Laser cleaning technology is now widely applied across multiple industrial sectors, demonstrating unique advantages in rust and paint removal, pre-welding and coating surface preparation, mold maintenance, cultural heritage restoration, and aerospace and electronics manufacturing. For rust and paint removal, laser cleaning can be applied to steel, aluminum, titanium, and other metal surfaces to efficiently remove oxide layers, rust, and paint coatings without damaging the substrate. In pre-welding and coating surface preparation, laser cleaning improves surface adhesion, ensuring a strong bond between welds or coatings and the substrate, significantly enhancing product quality and reliability.

In mold maintenance, laser cleaning effectively removes residues from rubber, tire, and injection molds, extending tool life and reducing maintenance costs. In cultural heritage restoration, laser cleaning removes dirt and oxide layers without damaging the underlying substrate, providing a safe and efficient method for preserving valuable artifacts. In aerospace and electronics manufacturing, laser cleaning ensures surface cleanliness and conductivity of precision components, guaranteeing assembly accuracy and stable performance.

These extensive applications demonstrate that laser cleaning machines have gradually become essential equipment in modern industrial cleaning and surface treatment. At the same time, they place higher demands on operators’ technical skills and safety awareness. Systematic training and strict adherence to operating procedures are essential to achieve efficient, safe, and reliable cleaning results across various materials and working conditions.

In summary, laser cleaning technology, with its high energy density, strong controllability, and environmentally friendly characteristics, provides an efficient, safe, and sustainable cleaning solution for modern manufacturing. While mastering the technology, operators must fully understand its energy characteristics, potential hazards, and safety requirements. Only with a solid grasp of technical principles, combined with standardized operating procedures and systematic training, can laser cleaning machines truly deliver high-efficiency, precise, and sustainable value in practical industrial applications.

Training Requirements for Laser Cleaning Machine Operators

Operating a laser cleaning machine is not as simple as “turn on—clean—turn off.” In reality, this work involves knowledge and skills from multiple disciplines, including optics, electrical engineering, mechanics, and safety management, requiring operators to possess comprehensive professional competence. To ensure the safety and efficiency of the operation process and to extend the equipment’s lifespan, companies must provide operators with a systematic, phased training plan. Training should not only include theoretical explanations but also practical operation, case analysis, and risk simulations to ensure operators can skillfully apply their knowledge in real-world work scenarios. The following is a detailed explanation of the main content and core modules of laser cleaning machine operator training.

Základy bezpečnosti laseru

Operators must first fully understand the basic principles of laser radiation and its potential hazards. Lasers have high brightness, high energy density, and extremely strong directionality. Improper operation or direct contact without protection can easily cause irreversible damage to the retina and skin. During training, the interaction mechanism between lasers and human tissues should be explained in detail, including photothermal effects, photochemical effects, and mechanical impact effects, so that operators deeply understand the severity of laser damage. Simultaneously, training should incorporate specific case studies to demonstrate the potential consequences of laser injuries, enabling operators to understand the importance of safety both intuitively and theoretically, thus maintaining constant vigilance and protective awareness in daily operations.

Školení bezpečnosti laseru

Laser Classification and Safety Regulations: According to the International Electrotechnical Commission (IEC 60825) standard, laser equipment is classified into four classes, from Class 1 to Class 4. Laser cleaning machines typically belong to Class 4 high-risk equipment, and their operation must be carried out in a strictly controlled environment. Training should cover relevant safety measures, such as the signage of laser work areas, the installation of warning lights, the location and use of emergency stop buttons,and ensuring operators know how to properly protect themselves and respond to potential hazards in any situation.

Personal Protective Equipment (PPE): Operators must be proficient in and correctly use laser safety glasses, gloves, and protective clothing. Training content should not only include basic wearing methods but also explain how to select appropriate protective lenses based on laser wavelength, as well as how to conduct daily inspections, maintenance, and periodic replacement of protective equipment to ensure constant protection during operation.

Control Measures and Interlocking Devices: The safety control system is a core element in accident prevention. Training should focus on explaining the functions and usage of devices such as laser protective shields, optical shutter systems, interlocking door locks, and safety relays. Operators should understand how these devices automatically cut off laser output in abnormal situations to ensure the safety of equipment and the operating environment. Simultaneously, through simulation exercises, operators should become proficient in handling various situations triggered by safety devices, improving their ability to respond to emergencies.

Equipment Operation and Maintenance Training

Machine Setup and Calibration: Operators need to master the adjustment methods for key parameters such as laser power, scanning speed, focal length, and spot size, and understand the specific impact of these parameters on cleaning results. Correct parameter settings not only effectively improve cleaning efficiency but also prevent damage to the workpiece substrate due to excessive laser energy, thereby reducing defect rates and material waste. Training can incorporate examples and comparative experiments to allow operators to intuitively understand the importance of parameter adjustment.

Standard Operating Procedures: Enterprises should establish comprehensive Standard Operating Procedures (SOPs), including pre-start checks, equipment preheating, cleaning process monitoring, and shutdown and safety reset procedures after operation. Operators must be familiar with the specific contents of the SOP documents and strictly follow them in actual operation. Repeated practice of standard procedures can effectively reduce operational errors and improve operational efficiency and safety.

Maintenance and Troubleshooting: Laser cleaning equipment consists of an optical system, cooling system, scanning system, and control software. Training should cover regular maintenance, such as lens cleaning, water cooling circulation checks, and electrical grounding tests, while also explaining common troubleshooting methods, such as laser power drops, scanning abnormalities, and cooling alarms. Case studies should be used to enable operators to initially identify the causes of problems and take appropriate measures, reducing equipment downtime and improving production continuity.

Software Operation and Data Management: With the development of intelligent laser cleaning equipment, operators’ proficiency in the software interface is equally crucial. Training should cover parameter setting, task programming, path optimization, and process recording, enabling operators to efficiently use the software to complete tasks while improving data management capabilities, achieving process traceability and optimization, and providing data support for subsequent production improvements.

Risk Management and Hazard Assessment

Risk Identification and Hazard Control: Training should guide operators to identify potential risks, including laser leakage, electrical short circuits, fume inhalation, and reflected light hazards, and teach methods for taking appropriate protective and isolation measures. Through systematic instruction and practical drills, operators can proactively identify risks in daily operations and prevent potential accidents.

Safety Planning and Emergency Response: Training should also teach how to develop safe operating procedures and emergency plans, including fire handling, equipment malfunction alarms, and personnel evacuation procedures. Regular emergency drills can strengthen operators’ practical response capabilities, enabling them to take quick and accurate measures in emergencies to ensure the safety of personnel and equipment.

Continuous Improvement and Safety Culture Building: Training is not just a one-time knowledge dissemination, but should establish a continuous improvement mechanism. Enterprises can continuously improve their overall safety management level through annual safety retraining, performance evaluations, and safety feedback mechanisms, ensuring that a safety culture permeates all levels of the enterprise and that operators maintain a constant safety awareness.

Regulatory Compliance and Record Keeping

Compliance with Safety Standards and Regulations: The use of laser cleaning equipment must comply with local and international safety standards, such as ISO 11553 (Safety Requirements for Laser Processing Equipment) and IEC 60825 (Laser Radiation Safety Standard). Training should help operators understand these regulatory requirements and implement them in daily operations, ensuring that the enterprise is free from legal and regulatory risks.

Record and Document Management: Enterprises should establish a complete system of training records, maintenance logs, safety checklists, and incident reporting. These documents are not only crucial for safety compliance but also provide reliable support for subsequent audits, risk tracing, and continuous improvement. Through scientific management of operational records, enterprises can better analyze operational data, summarize experiences, and optimize safety processes.

Systematic operator training is fundamental to ensuring the safe and stable operation of laser cleaning equipment. Through a comprehensive training system encompassing safety knowledge education, skills training, risk management, and compliance implementation, enterprises can effectively reduce accident rates and improve production efficiency and equipment stability. Excellent operators not only need to master the technology but also understand safety management. Only when safety and efficiency are equally emphasized can laser cleaning machines truly realize their high-efficiency, precise, and environmentally friendly value, bringing long-term and reliable production benefits to enterprises.

souhrn

Laser cleaning machines, as a highly efficient and environmentally friendly surface treatment technology, are rapidly changing the landscape of the global industrial cleaning industry. However, any high-energy equipment carries potential risks, making the establishment of a systematic safety training system crucial. Qualified operators must not only master basic laser safety knowledge and protective measures but also be familiar with equipment operation procedures, maintenance techniques, and the usage logic of the software system. Simultaneously, risk management, hazard assessment, and strict regulatory compliance can minimize the accident rate and ensure the safety of personnel and equipment.

For enterprises, investing in a comprehensive training system not only improves operational efficiency and equipment lifespan but also enhances the safety and controllability of the production process, thereby maintaining a stable advantage in the highly competitive manufacturing market. The future of laser cleaning technology will increasingly rely on a professional and standardized talent system to drive continuous technological development and innovation.

Získejte laserová řešení

When selecting laser cleaning equipment, efficiency, safety, and reliability are the most important factors for enterprises. AccTek Laser equipment, with its advanced laser technology, intelligent operating interface, and comprehensive safety protection system, can provide customers with efficient, stable, and safe cleaning solutions. Whether it’s rust removal, paint removal, or surface treatment, our equipment can meet the needs of different industrial scenarios. We also provide operational training and technical support, enabling businesses to quickly achieve efficient production.

Výběr AccTek Laser means choosing an efficient, safe, and reliable industrial cleaning partner.

Kontaktní informace

- [email protected]

- [email protected]

- +86-19963414011

- č. 3 zóna A, průmyslová zóna Lunzhen, město Yucheng, provincie Shandong.

Získejte laserová řešení