How to ensure consistent welding quality when using laser welding machines?

In modern manufacturing, consistent welding quality directly impacts product reliability, lifespan, and a company’s professional image in the market. Any welding instability can be amplified in subsequent assembly or use stages, ultimately leading to batch quality incidents. This is especially true in industries with high precision and strength requirements, such as sheet metal processing, automotive parts, and precision equipment manufacturing. Welding defects not only mean increased rework costs but can also lead to delivery delays, customer claims, and even a decline in brand trust. Therefore, establishing a repeatable, traceable, and quantifiable welding quality control mechanism has become a fundamental capability for modern manufacturing enterprises.

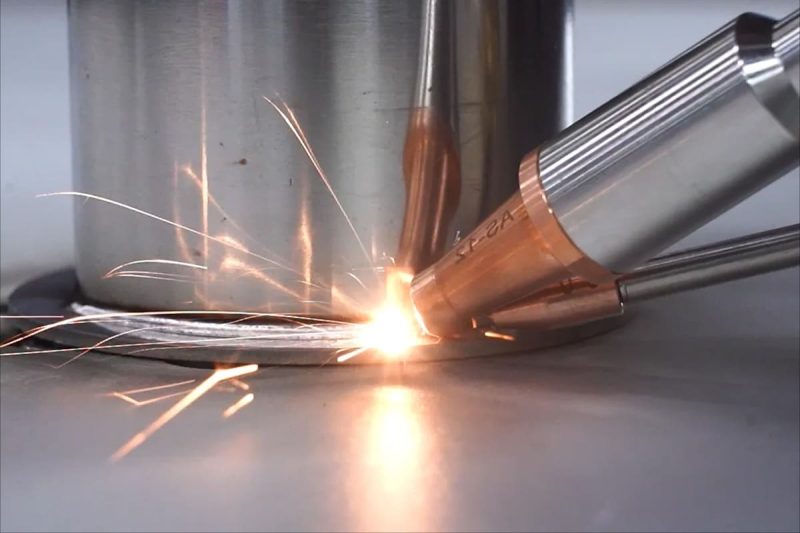

Laser welding machines, with its advantages of concentrated energy, small heat-affected zone, and high degree of automation, is increasingly being used by companies to improve production efficiency and welding precision. However, laser welding also places stricter requirements on process parameters, equipment stability, and operating procedures. Fluctuations in laser power, focus position deviation, welding speed mismatch, or inconsistent material surface conditions can all directly affect weld formation and weld strength. This article starts by analyzing the key factors affecting the stability of laser welding quality, systematically outlining controllable variables and common risk points. Based on actual production scenarios, it provides practical control methods and best practices to help enterprises build a long-term, stable, and sustainable laser welding quality assurance system.

Table of Contents

Understanding the Core Factors Affecting Welding Quality

To ensure consistent welding quality, it’s essential to understand which factors influence the final result. Laser welding is a complex process involving multiple aspects, including materials, processes, equipment, and personnel. Fluctuations in any of these aspects can lead to quality problems.

The Key Impact of Material Properties

Materials are the foundation of weld quality. Even materials of the same grade from different batches may differ in chemical composition and physical properties. These differences affect laser absorption rate, melting behavior, and solidification characteristics. For example, slight variations in carbon content in stainless steel can alter the weld microstructure and cracking tendency. Fluctuations in magnesium or silicon content in aluminum alloys can affect weld strength and hot cracking susceptibility.

The surface condition of the material significantly impacts weld quality. Oxide layers reduce the laser absorption rate, leading to insufficient penetration or unstable welding. Oil and moisture create porosity, affecting weld density. Even minute amounts of surface contamination can be amplified under high-energy-density laser light, causing noticeable defects. Therefore, establishing strict incoming material inspection and storage management systems is crucial.

Tolerance control of material thickness is equally critical. Laser welding has a relatively narrow process window; variations in thickness of even tens of micrometers can affect the penetration depth. If the sheet material is of uneven thickness, the same welding parameters may result in penetration in some areas and incomplete penetration in others. For precision welding applications, material thickness tolerances should be controlled within ±0.05 mm or even more stringently.

The Importance of Joint Design and Preparation

Joint design determines the difficulty and upper limit of weld quality. Butt joints require small assembly gaps, generally not exceeding 10% of the plate thickness; otherwise, collapse or incomplete fusion is likely. Lap joints require a tight fit between the two layers of material; any air gap will affect heat conduction and weld pool stability. Corner joints require careful attention to the laser incident angle to avoid energy loss.

Assembly accuracy directly affects weld consistency. If the workpiece is not accurately positioned, the laser beam may deviate from the joint center, causing weld misalignment or burn-through. Fixture design should ensure that the workpiece does not move or deform during welding. For thin plate welding, the effect of thermal deformation must also be considered, and appropriate clamping methods and sequences should be used to control warping.

Edge preparation quality is often overlooked. Burrs left from cutting or machining can interfere with laser energy distribution, causing weld instability. Inconsistent dimensions and shapes of blunt edges can lead to variations in weld penetration. For critical applications, the edges to be welded should be ground or precision-machined to ensure that dimensions and surface quality meet requirements.

Precise Control of Laser Welding Parameters

Laser power is the parameter that most directly affects weld quality. Insufficient power can lead to inadequate penetration, lack of fusion, or poor weld formation. Excessive power can cause burn-through, spatter, or porosity. The ideal power setting should ensure reliable penetration while allowing for some margin to accommodate fluctuations in material or assembly.

Welding speed is closely related to power, as both determine the linear energy input. Too slow a speed can cause overheating and deformation, while too fast a speed will result in insufficient penetration. The optimal speed needs to be determined experimentally, maximizing efficiency while maintaining quality. For long welds, speed adjustments at the start and end points should also be considered to avoid defects at these locations.

The focal point significantly affects weld shape and penetration depth. Energy density is highest when the focal point is at the surface, suitable for thin plate welding. A focal point slightly below the surface allows for deeper penetration. Defocusing is typically adjusted between -2mm and +2mm. The optimal defocusing amount may vary for different thicknesses or materials and needs to be determined through process testing.

The type and flow rate of the shielding gas are also important parameters. Argon is suitable for most materials, while helium or an argon-helium mixture is used for materials with high thermal conductivity. The gas flow rate must be sufficient to protect the molten pool, but not too high, lest it disperse the protective gas or disturb the molten pool. The nozzle position and angle need to be carefully adjusted to ensure that the gas covers the entire welding area.

Accuracy of Machine Setup and Calibration

The laser generator’s operating status needs to be checked regularly. Beam quality degrades over time, affecting welding results. While fiber laser generators offer good stability, their output power can still decrease due to pump diode aging. It is recommended to check the actual output power monthly or quarterly with a power meter to ensure consistency with the set value.

The cleanliness and alignment of the optical path system are crucial. Contaminants on the protective lenses can absorb or scatter the laser, reducing welding quality and potentially damaging the lenses. Positional deviations of the focusing lens can alter the focal point and spot size. Standard operating procedures for lens cleaning and replacement should be established, recording the time and results of each maintenance.

The accuracy of the motion system directly affects the weld position and trajectory. The repeatability of the servo motor should be within ±0.05mm; wear on the guide rails and sliders will reduce accuracy. Regularly inspect and calibrate the motion system, replacing worn parts as necessary. For robotic welding, regular TCP (tool center point) calibration is also required to ensure accurate welding head positioning.

The reliability of the monitoring and sensing systems cannot be ignored. Temperature sensors, position sensors, and vision systems require regular calibration. If sensor readings are inaccurate, the feedback control system will make incorrect adjustments, thus reducing quality stability. A sensor calibration record should be established, documenting the calibration date, method, and results.

Best Practices for Ensuring Consistent Welding Quality

After understanding the influencing factors, it is necessary to establish systematic control measures to ensure consistent quality. Efforts in any single step are insufficient; comprehensive management is required, encompassing process control, personnel training, quality inspection, and continuous improvement.

Process Control and Real-Time Monitoring

Establishing standardized welding procedure specifications is the foundation of quality control. The procedure specification should detail all key elements, including material requirements, joint types, welding parameters, shielding gas, and inspection standards. Each parameter should have clearly defined setpoints and allowable deviation ranges. The procedure specification is not static but should be continuously optimized and updated based on production practice.

Monitoring and recording process parameters is crucial. Modern laser welding systems are typically equipped with data acquisition capabilities, capable of recording parameters such as power, speed, and temperature in real time. This data is not only used for quality traceability but also for statistical analysis to identify parameter drift trends. If a parameter begins to deviate from the normal range, timely adjustment or maintenance of the equipment is necessary.

Real-time monitoring technology can detect problems during the welding process. Optical monitoring systems determine the welding status by observing images of the molten pool or plasma plume. Acoustic monitoring utilizes the characteristics of welding sounds to identify defects. These monitoring systems can be linked with welding equipment, immediately stopping or triggering an alarm upon detecting an anomaly to prevent a large number of defective products.

Statistical Process Control (SPC) is an effective tool for ensuring quality stability. By collecting welding process data and quality inspection data and creating control charts, it’s possible to determine whether the process is under statistical control. When data points exceed control limits or exhibit a non-random trend, it indicates an anomaly in the process, requiring investigation and corrective action.

First-piece inspection and routine inspection systems are indispensable. Before the start of each shift, the first product should undergo a comprehensive inspection to confirm the correctness of equipment status and process parameters. Regular spot checks should be conducted during production to identify quality problems early. The inspection frequency should be determined based on process capability and product importance; critical products may require inspection of every piece, while general products can be inspected proportionally.

Operator Training and Skills Development

The skill level of operators has a significant impact on welding quality. Even with highly automated equipment, human intervention is still required for loading and unloading workpieces, setting parameters, and handling abnormal situations. A systematic training program should be established, including laser welding principles, equipment operation, process requirements, quality standards, and safety procedures.

The skill level of operators has a significant impact on welding quality. Even with highly automated equipment, human intervention is still required for loading and unloading workpieces, setting parameters, and handling abnormal situations. A systematic training program should be established, including laser welding principles, equipment operation, process requirements, quality standards, and safety procedures.

Theoretical training should be combined with practical operation. Operators should understand how welding parameters affect quality and why these parameters are set in a particular way. Through hands-on practice, they should master equipment usage techniques and methods for handling common problems. New employees should undergo thorough training and assessment before operating independently to avoid quality issues or equipment damage due to improper operation.

Skills certification and continuing education help maintain operational proficiency. An internal skills level system can be established to encourage employees to continuously learn and improve. For key positions, operators can be required to obtain external certifications, such as laser safety certificates or welding operation certificates. Regular training and assessments should be organized to ensure that employees’ skills do not deteriorate.

Establish an experience-sharing and knowledge management mechanism. Experienced employees should be encouraged to summarize their work experiences and create operating manuals or training materials. Technical exchange meetings should be organized to discuss problems encountered in production and their solutions. Documenting and databasing this knowledge allows new employees to learn quickly, while experienced employees can also consult it.

Prevention is more important than correction. Training operators helps them understand the causes and prevention methods of common defects. For example, how to identify surface contamination, how to determine if assembly gaps are appropriate, and how to judge the normality of the process from welding sounds. Cultivating employees’ quality awareness and sense of responsibility makes everyone a guardian of quality.

Quality Assurance and Inspection System

Establishing a comprehensive quality inspection system is the last line of defense for ensuring product quality. Inspection should be integrated throughout the entire production process, including incoming material inspection, in-process inspection, and final inspection. Each stage of inspection has different focuses and methods.

Incoming material inspection mainly checks the specifications, composition, surface quality, and geometric dimensions of materials. There should be clear inspection standards and sampling plans. For critical materials, chemical analysis or mechanical property testing may be required. Non-conforming materials should be isolated and returned to the supplier to prevent them from entering production.

In-process inspection monitors the quality of the welding process and intermediate products. In addition to parameter monitoring, the appearance, dimensions, and penetration of welds should be checked regularly. For automated production lines, online inspection systems can be installed to achieve 100% inspection. Commonly used online inspection methods include visual inspection, infrared thermography, and ultrasonic thickness measurement.

For critical applications, destructive testing is a reliable method for verifying weld quality. Tensile tests measure joint strength, bending tests check plasticity and weld quality, and impact tests assess toughness. Metallographic analysis observes the weld microstructure, and hardness tests check the hardening degree of the heat-affected zone. Although destructive testing is costly, it provides a comprehensive understanding of weld quality and a basis for process optimization.

Handling and tracing nonconforming products are crucial. Upon discovery of nonconforming products, they should be immediately isolated and the cause analyzed. If it is a systemic problem, production must be stopped and corrected. If it is an isolated issue, the scope of impact should be determined, and rework or scrapping should be implemented. A quality record and traceability system should be established, allowing each batch of products to be traced back to the materials used, operators, equipment, and process parameters.

Feedback Mechanisms and Continuous Improvement

The collection and analysis of quality data are the foundation of continuous improvement. A quality database should be established to record all inspection results, nonconforming product information, and customer feedback. This data should be analyzed regularly to identify patterns and trends in quality problems. Common analytical tools include Pareto charts, cause-and-effect diagrams, and failure mode analysis.

Root cause analysis can find the true root cause of a problem. When quality problems arise, don’t stop at the surface symptoms; delve deeper to investigate why they occurred. Use the 5 Whys analysis method, asking five consecutive “whys” until the root cause is found. For example, why is there porosity in the weld? Because there is moisture on the material surface. Why is there moisture? Because the storage environment is humid. Why is the environment humid? Because the warehouse lacks dehumidification equipment. Only after finding the root cause can effective corrective actions be developed.

Corrective and preventive actions must be treated differently. Corrective actions target problems that have already occurred, preventing recurrence. Preventive actions, on the other hand, take action before problems occur to eliminate potential risks. Both must have clearly defined responsibilities and completion times, and their effectiveness must be verified after implementation.

Process optimization is an important aspect of continuous improvement. Even if the current process meets quality requirements, there is still room for improvement to increase efficiency, reduce costs, or enhance reliability. Design of Experiments (DOE) can be used to systematically study the impact of parameters on quality and find the optimal parameter combination. New technologies, such as oscillating welding, hybrid welding, or intelligent control, can also be introduced to improve process capabilities.

Employee participation is crucial for continuous improvement. Frontline employees understand the actual production situation best, and their improvement suggestions are often very valuable. Incentive mechanisms should be established to encourage employees to provide suggestions for improvement. Quality circles or improvement teams can be organized to involve employees in problem-solving and process optimization. When employee suggestions are adopted and bring benefits, they should be recognized and rewarded.

Benchmarking can broaden horizons. Study best practices from leading companies in the same industry, learning their quality management methods and technological innovations. Attend industry conferences and exhibitions to understand the latest equipment and technological developments. Establish partnerships with suppliers, customers, and research institutions to jointly solve technical challenges.

Regularly audit and evaluate the effectiveness of the quality management system. Internal audits check whether procedures are followed, records are complete, and equipment is calibrated. Management reviews, chaired by senior management, assess the achievement of quality objectives and determine resource allocation and improvement directions. External audits or certifications such as ISO 9001 can provide objective evaluations and enhance customer confidence.

Technological Aid to Quality Control

Modern technologies provide powerful tools for quality control in laser welding. The rational use of these technologies can significantly improve quality, stability, and production efficiency.

Intelligent Monitoring and Adaptive Control

Visual monitoring systems observe the welding process through high-speed cameras, analyzing the molten pool morphology, weld contour, and defect characteristics in real time. Advanced systems equipped with image processing algorithms and artificial intelligence can automatically identify normal and abnormal welding states. Once a problem is detected, the system can automatically adjust parameters or issue an alarm.

Spectral Monitoring utilizes the spectral characteristics of plasma emission to determine welding quality. Different elements emit light at specific wavelengths; analyzing the spectrum reveals the composition and temperature of the molten pool. Studies have shown that certain spectral characteristics are strongly correlated with welding defects such as porosity and lack of fusion, and can be used for online quality prediction.

Acoustic Emission Monitoring is a non-contact monitoring method. Pore formation, crack initiation, and metal evaporation during the welding process all emit specific acoustic signals. By installing acoustic emission sensors on the workpiece, these signals can be detected in real time, and defects can be identified. This method is particularly suitable for detecting internal defects and is an effective complement to other methods.

Adaptive control systems can automatically adjust welding parameters based on monitoring information. For example, when a change in material thickness is detected, the system automatically adjusts the power or speed to maintain a stable penetration depth. When an assembly gap is detected, the system can reduce the speed or oscillate the welding head to fill the gap. This closed-loop control greatly improves adaptability to changes.

Digitalization and Data-Driven Approach

The Production Management System (MES) integrates welding equipment and quality inspection data to achieve full-process digital management. The production process of each product is fully recorded, including the batch of materials used, operators, equipment numbers, process parameters, and inspection results. This data can be used for quality traceability, trend analysis, and performance evaluation.

Big data analytics can uncover hidden patterns from massive amounts of data. Through machine learning algorithms, predictive models between welding parameters and quality results can be established. These models can help optimize parameter settings, predict potential quality problems, and even achieve predictive maintenance, performing servicing before equipment failure.

Digital twin technology creates virtual models of the welding process, simulating and optimizing processes without actual production. Digital twins allow for rapid assessment of the impact of parameter changes, development of welding processes for new products, and operator training. Digital twins can also run synchronously with the actual production system, comparing predicted and actual results in real time to promptly detect anomalies.

Cloud platforms and remote monitoring enable quality management across multiple factory locations. Equipment status, production data, and quality information are uploaded to the cloud, accessible to managers from anywhere. Equipment manufacturers can provide remote technical support for rapid diagnosis and problem-solving. This is particularly valuable for global manufacturing companies.

Building a Quality Culture

While technology and processes are important, a quality culture is the fundamental guarantee of sustained and stable quality. A quality culture is the shared understanding, attitude, and behavior regarding quality by everyone in the organization.

Leadership’s emphasis and commitment are the starting point for a quality culture. Managers must lead by example, prioritizing quality and providing the necessary resources and support for quality improvement. Quality objectives should be integrated into the company’s strategy, and quality performance should be a key performance indicator.

Total participation is the core of a quality culture. Quality is not just the responsibility of the quality department; every department and every employee is responsible for quality. Designers must consider manufacturability, purchasing personnel must select reliable suppliers, operators must strictly adhere to procedures, and inspectors must ensure quality control.

Customer orientation guides the direction of quality improvement. It is essential to deeply understand customer needs and expectations and translate them into quality standards and process requirements. Establish a customer feedback mechanism to promptly handle customer complaints and evaluate quality from the customer’s perspective. Customer satisfactionis the ultimate standard for measuring the effectiveness of quality management.

Continuous improvement should be an integral part of daily work. Never be complacent; always seek better methods. Encourage innovation and experimentation; allow for failure, but learn from it. Institutionalize improvement projects, regularly review progress, and share successful experiences.

Summary

Ensuring consistent laser welding quality requires a systematic approach and continuous effort. From material control, joint preparation, parameter settings, to equipment maintenance, every step must be meticulously managed. Establishing standardized process procedures, implementing rigorous process control and quality inspection, training and developing employee skills, and utilizing modern technologies to improve monitoring and analysis capabilities are crucial.

More importantly, establishing feedback mechanisms and a culture of continuous improvement is essential. Quality issues are inevitable; the key is how to quickly identify, deeply analyze, and effectively resolve them. By collecting and analyzing quality data, identifying improvement opportunities, and taking corrective and preventative measures, process capabilities can be continuously improved.

Laser welding technology is rapidly evolving, with new equipment, materials, and applications constantly emerging. Quality management must also keep pace, learning and applying new methods and tools. Intelligent monitoring, data analysis, and artificial intelligence technologies have opened up new possibilities for quality control, but the human factor remains critical. Cultivating quality awareness, improving skill levels, and establishing a quality culture are essential to achieving long-term, stable, high-quality production.

For AccTek Laser, quality is the foundation of survival and development. In a highly competitive market, only by consistently providing high-quality products can we win customer trust and build brand reputation. Investing in the establishment and improvement of a quality management system, while requiring time and resources, yields substantial returns. It reduces waste and rework, increases production efficiency, enhances customer satisfaction, and ultimately achieves sustainable business success.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions