What Are the Common Problems of Laser Welding Machines?

With the continued growth in demand for intelligent manufacturing and precision machining, laser welding technology is becoming an indispensable core process in modern industry. As a key piece of equipment in high-end manufacturing, laser welding machines, with their advantages of high energy density, non-contact processing, high welding precision, and low thermal impact, are widely used for welding metals such as stainless steel, carbon steel, aluminum alloy, and copper. They play a vital role in industries such as automotive, aerospace, electronics, medical devices, and precision molds.

In recent years, the widespread adoption and technological advancements of fiber laser welding machines have resulted in faster welding speeds, finer welds, and less distortion, significantly improving production efficiency and quality. However, even high-performance laser welding equipment cannot completely avoid certain technical challenges in actual industrial applications. For example, inconsistent weld strength, beam energy attenuation, high material reflectivity, an excessively large heat-affected zone, and cooling system malfunctions can directly impact welding performance and equipment stability.

Therefore, understanding and mastering the causes and solutions to these common laser welding machine issues is crucial for improving production reliability and extending equipment life. This article systematically analyzes welding quality, beam transmission, thermal management, material compatibility, power stability, software control, and operational maintenance. Based on practical application scenarios, it offers professional recommendations and optimization solutions to help users achieve higher consistency, lower defect rates, and superior welding performance in daily production. Whether you’re engaged in laser equipment manufacturing, metal welding processing, or responsible for optimizing automated production line technology, this article will provide you with practical technical references and industry insights.

Table of Contents

Laser Welding Overview

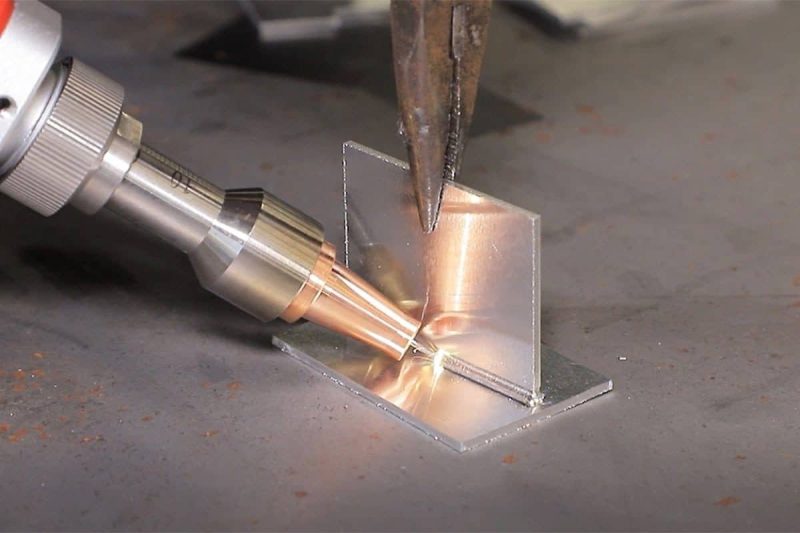

Laser welding is an advanced welding process that uses a high-energy-density laser beam as a heat source to quickly and precisely join metal and non-metallic materials. Its core principle is to use a fiber laser generator (Fiber Laser Generator) or a solid-state laser generator (Solid-State Laser Generator) to output a high-power-density focused beam, instantly melting the weld area and forming a strong weld. Due to its non-contact, consumable-free, and highly concentrated energy characteristics, laser welding technology is gradually replacing traditional methods, such as TIG welding, MIG welding, and spot welding. It is becoming the mainstream welding method in modern manufacturing.

Compared with traditional welding methods, laser welding offers the following significant advantages:

- Fast welding speed: Energy is concentrated, and the molten pool forms quickly, significantly improving production efficiency.

- Reduces deformation: Heat input is controllable, making it suitable for high-precision component processing.

- Widely applicable materials: Suitable for welding a variety of metals, including stainless steel, carbon steel, aluminum, copper, and galvanized sheet.

- Beautiful weld seams: No extensive post-weld polishing or post-processing is required, making it suitable for the manufacture of high-end exterior components.

- High degree of automation: Easy integration with robots or automated production lines, enabling intelligent welding.

Currently, mainstream laser welding equipment on the market includes:

- Handheld laser welding machines: Flexible and convenient, suitable for welding small and medium-sized workpieces such as metal doors and windows, cabinets, and computer cases.

- Automated laser welding workstations: Supporting mass production, equipped with a multi-axis control system and precision positioning mechanism.

- Laser welding robot systems: Combining industrial robots with vision recognition, they enable multi-angle automated welding of complex workpieces, suitable for high-precision applications such as automotive manufacturing and electronic components.

With the increase in fiber laser generator power and the development of intelligent welding process control technology, the application scope of laser welding is continuously expanding. Whether it is deep penetration welding of thick plates, precision welding of thin plates, or welding of dissimilar metals, laser welding provides higher joint strength and better process stability.

Due to its high efficiency, precision, and automation, laser welding has become a key supporting technology for intelligent manufacturing. Selecting the right laser welding machine and process parameters not only improves product quality and consistency but also effectively reduces production costs. For companies seeking high-quality metal welding solutions, mastering laser welding technology is a crucial step towards high-end manufacturing.

Common Problems and Solutions for Laser Welding Machines

Although laser welding machines offer significant advantages in welding speed, weld accuracy, and energy efficiency, factors such as the equipment operating environment, operator experience, material properties, and optical system condition can lead to weld instability or product defects over long-term production.

To help users more efficiently identify problems and develop effective solutions, the following systematically analyzes sixteen common laser welding problems, their main causes, and their solutions.

Inconsistent Weld Quality

Description: Rough weld surface, uneven color, or unstable strength.

Cause: Fluctuating laser energy output, weld path deviation, uneven material thickness, or gap.

Solution:

- Check and calibrate laser power output to maintain a stable energy curve.

- Optimize process parameters such as welding speed, focal length, and shielding gas flow;

- Use an automatic positioning and tracking system to ensure a precise weld path;

- Adjust power distribution for materials of varying thicknesses to ensure consistent penetration.

Beam Quality Issues

Description: Uneven weld depth, unstable weld pool, and insufficient energy concentration.

Cause: Damaged fiber, contaminated lens, or aging laser generator.

Solution:

- Regularly clean the lens and reflector to prevent the accumulation of dust and spatter.

- Check the fiber connector for looseness or contamination.

- Replace aging fiber laser generator components;

- Periodically test the beam quality to ensure beam stability.

Porosity and Cracks

Description: Porosity, cracks, or slag inclusions appear in the weld, affecting mechanical strength and sealing performance.

Cause: High gas content in the material, insufficient shielding gas flow, or rapid cooling leading to concentrated thermal stress.

Solution:

- Clean oil and oxide layers from the workpiece surface.

- Optimize the shielding gas flow and angle (such as argon, nitrogen, or helium);

- Control the cooling rate during welding to prevent excessive thermal stress.

- Use degassed metal materials to reduce internal porosity.

Beam Transmission Issues

Description: Unstable laser energy delivery, resulting in fluctuating weld depth.

Cause: Misaligned optical path, reflector angle deviation, or vibration affecting transmission accuracy.

Solution:

- Regularly inspect and realign the optical system.

- Use anti-vibration mounts and high-reflectivity protective lenses;

- Avoid installing the equipment in high-vibration environments.

- Calibrate the transmission fiber path to ensure energy consistency.

High Material Reflectivity

Description: Highly reflective metals such as aluminum and copper absorb laser energy poorly, resulting in welding difficulties.

Cause: The laser wavelength does not match the material’s absorptivity, resulting in severe energy reflection.

Solution:

- Select a fiber laser generator with a wavelength more suitable for metal welding.

- Preheat the highly reflective material to increase absorptivity.

- Use an anti-reflection welding head and polarization control technology.

- Adjust the laser incident angle to reduce specular reflection.

Thermal Management Issue

Description: Heat buildup causes burn-through, deformation, or blackening of the weld.

Cause: Excessive laser power, insufficient cooling, or improper heat dissipation structure design.

Solution:

- Balance laser power and welding speed to prevent overheating.

- Optimize fixture and heat sink design to ensure timely heat transfer.

- Use pulse welding mode for thick plate welding to reduce heat input.

- Use an efficient cooling system to prevent thermal damage.

Material Compatibility and Weldability

Description: Poor weldability of dissimilar metals and a weak fusion layer.

Cause: Large melting point difference, mismatched thermal expansion coefficients, or intermetallic reactions that form brittle phases.

Solution:

- Use a transition layer or intermediate welding material.

- Control laser energy input to avoid excessive melting.

- Use a multi-layer welding process to distribute stress.

- Perform preliminary experiments on dissimilar metal combinations to determine optimal parameters.

Joint Preparation and Assembly Issues

Description: Misaligned welds or excessive gaps lead to uneven welds.

Cause: Imprecise workpiece assembly and improper fixture structure.

Solution:

- Improve fixture positioning accuracy;

- Use automated assembly systems or vision-assisted systems;

- Control the weld gap to ≤2mm to ensure good weld fusion.

Focusing and Alignment Issues

Description: Laser focus deviation causes decreased energy concentration.

Cause: Optical lens contamination, sensor error, or focal drift.

Solution:

- Regularly calibrate the focal position.

- Clean the focusing lens and protective lens.

- Use an autofocus system and a real-time monitoring sensor.

Unstable Laser Power

Description: Fluctuations in laser output power cause poor welding consistency.

Cause: Laser source aging, power supply fluctuations, or unstable control signals.

Solution:

- Use a stable power supply system.

- Regularly monitor the laser output power curve.

- Replace aging components to ensure light source stability.

Contamination and Cleanliness Issues

Description: Black spots, spatter adhesion, or discontinuous welds appear on the weld seam.

Cause: Oil, dust, or contamination on the workpiece surface.

Solution:

- Use a laser cleaning machine for surface pretreatment before welding.

- Clean the focusing lens, protective lens, and safety glass.

- Maintain a clean operating environment to prevent contaminants from entering the optical path.

Mechanical and Electrical Failures

Description: Control system unresponsive, servo drive anomaly, or emergency stop alarm.

Cause: Loose electrical connections, aging circuitry, or driver module failure.

Solution:

- Check the circuit interface and control circuit board.

- Regularly replace aging cables and modules;

- Use anti-static devices to reduce electrical interference.

Cooling System Failure

Description: The Laser generator overheats, or the system shuts down due to an alarm.

Cause: Insufficient coolant circulation, radiator blockage, or water pump malfunction.

Solution:

- Use a high-efficiency industrial chiller.

- Regularly replace coolant and clean the filter system.

- Check the sensitivity of the flow alarm and temperature control system.

Software and Control System Issues

Description: Welding program errors, lost parameter settings, or communication anomalies.

Cause: Incompatible software versions, control module update failure.

Solution:

- Update the control software version promptly.

- Regularly back up welding parameters and program configurations;

- Ensure stable data communication lines.

Operator Skills and Training

Description: Welding defects or equipment damage caused by improper operation.

Cause: Lack of systematic training and insufficient understanding of laser welding parameters.

Solution:

- Regularly organize laser welding training courses;

- Establish standard operating procedures (SOP);

- Implement an operator certification system to ensure standardized operations.

Maintenance and Downtime

Description: Frequent equipment downtime reduces production efficiency.

Cause: Lack of a maintenance plan and untimely replacement of worn parts.

Solution:

- Develop a periodic maintenance and inspection plan;

- Use genuine, certified parts to ensure system compatibility.

- Record operating data to proactively identify potential failures.

Although laser welding machines offer advantages such as high efficiency, precision, and low loss, any high-precision equipment requires sound maintenance and operation. Regular calibration, cleaning of the optical system, optimization of process parameters, and enhanced personnel training can effectively reduce welding defects, extend equipment life, and improve production consistency.

Overall, only when the five key elements—equipment, process, materials, personnel, and environment—are simultaneously stable can fiber laser welding machines truly achieve optimal performance and create sustainable production value and competitiveness for enterprises.

Preventive Measures and Best Practices

In the daily production of laser welding machines, preventive maintenance and standardized operations are key to ensuring consistent weld quality and long-lasting equipment performance. Many welding defects and equipment failures are not due to design issues, but rather to the operating environment, improper maintenance, or inappropriate parameter settings. Systematic preventive measures and standardized operating procedures can not only effectively reduce downtime but also significantly extend the service life of the laser generator and key components.

Regular Maintenance

A laser welding system consists of core components such as the laser generator, optical path system, cooling system, and control system. Each component requires regular inspection and maintenance.

- Optical Path Cleaning: Regularly wipe the protective lens and reflector to prevent dust, oil, or metal vapor from adhering to the beam quality.

- Power Testing: Test the laser power output curve monthly. If power degradation is detected, adjust or replace the optical components promptly.

- Cooling System Maintenance: Keep the coolant clean and replace it on schedule, clean the water filter, and ensure the laser generator maintains stable temperature control.

- Mechanical Lubrication: Lubricate the slide rails and transmission components to prevent mechanical wear that may affect welding accuracy.

Professional Operator Training

High-quality welding depends not only on equipment performance but also on the operator’s technical proficiency.

- Standardized Operating Procedures (SOPs): Require operators to strictly adhere to parameter settings, welding paths, and cooling methods.

- Safety Standards Training: Master laser protection knowledge, including the use of protective glasses and laser reflection protection measures.

- Advanced Skills Training: Regular training is organized to learn the latest laser welding technology, material processing, and equipment commissioning methods.

Environmental Control

Laser welding requires a highly stable working environment.

- Temperature and Humidity Control: Maintain a constant temperature (20°C ± 2°C) and humidity of 40%-60% to prevent condensation on the lens and uneven thermal expansion of the material.

- Dust- and vibration-resistant design: Avoid installing the equipment in dusty or vibrating areas of the workshop.

- Air Quality Management: Use a fume extraction and dust removal system to prevent smoke accumulation from affecting beam transmission.

Power Supply Stability

Laser welding places extremely high demands on the power supply. Voltage fluctuations can cause unstable laser output, thus affecting weld consistency.

- Use an industrial stable power supply.

- Check the grounding system to ensure a safe and reliable current loop.

- Install the equipment with a UPS to prevent data loss or optical system damage caused by sudden power outages.

High-quality materials and accessories

The quality of the materials and accessories is crucial for laser welding.

- Use high-purity welding materials with clean surfaces.

- Select genuine, certified optical lenses, nozzles, and protective glasses;

- Regularly evaluate the quality and stability of welding wire, gas, and coolant.

By establishing a comprehensive preventive maintenance program and operating standards, companies can significantly reduce the failure rate of laser welding machines and improve production line continuity and welding consistency. From laser generator performance maintenance to comprehensive management of environmental control, power supply stability, and personnel training, every detail directly impacts the final welding result.

Summary

Laser welding technology, as a key process in modern manufacturing, is gradually replacing traditional welding methods and becoming a core tool for high-precision, high-efficiency production. Its widespread application in automotive, aerospace, electronic packaging, medical devices, metalworking, and other fields fully demonstrates its comprehensive advantages in welding speed, energy control, and weld quality.

However, to continuously maximize the performance of laser welding machines, relying solely on advanced hardware is far from enough. Equipment stability, optical system cleanliness, cooling system reliability, and operator expertise all directly impact the stability and consistency of welded products. Through regular maintenance, standardized operations, strict environmental control, and ongoing training, companies can effectively avoid common welding problems such as weld porosity, energy fluctuations, and cracks, thereby improving overall production quality and efficiency.

Furthermore, with the accelerating trend toward automation and intelligent manufacturing, laser welding equipment is evolving towards intelligent monitoring, remote diagnostics, and modular integration. In the future, laser welding will no longer be merely a heat source tool but a vital component of the entire intelligent manufacturing system. If companies can plan technology upgrades and maintenance systems, they will have a greater advantage in the fierce manufacturing competition.

Find a Laser Solution

If you’re looking for high-performance, stable, and reliable fiber laser welding machines, AccTek Laser is your trusted partner. We are committed to providing integrated laser welding solutions, from equipment design and application optimization to after-sales service, to global customers.

- Diverse Equipment Selection: From handheld laser welders to automated welding workstations and robotic laser welding systems, we cater to diverse industries and production scales.

- Core Technology Advantages: Utilizing a highly stable laser generator, intelligent temperature-controlled cooling systems, and precision optical path design ensures consistently high-quality welding output.

- Global Service Support: Remote technical diagnostics, video training, and localized after-sales support ensure fast access to professional support in any country.

- OEM and Customized Services: Welding heads, workstations, control systems, and software interfaces can be customized to meet your production needs, enabling more flexible automated integration.

Choosing AccTek Laser means choosing more than just a piece of equipment; it means choosing a proven, professional, and reliable laser welding system partner. Let laser technology become the driving force behind your manufacturing upgrades, and precision welding become the core of your competitiveness.

Description: Fluctuations in laser output power cause poor welding consistency.

Description: The Laser generator overheats, or the system shuts down due to an alarm.

Contact information

- [email protected]

- [email protected]

- +86-19963414011

- No. 3 Zone A, Lunzhen Industrial Zone,Yucheng City , Shandong Province.

Get Laser Solutions