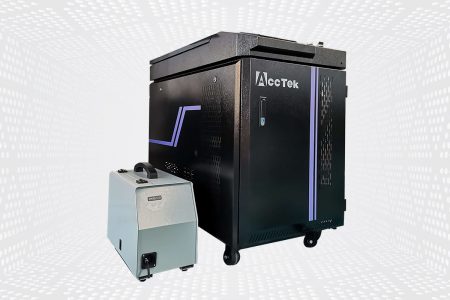

Copper Laser Welding Machine

Photoelectric Technology

AccTek Laser focus on designing and manufacturing photoelectric-related system. We provide accurate and exquisite processing quality with leading R&D capability.

Integration Ability & Experienced

With an experienced, completed, and elite R&D team, customized such as automated, integrated with the robot, system integration, etc. are all available.

Professional Service

AccTek Laser's laser welding machine is a professional laser welding machine designed and manufactured in China. Our elite engineering team provides related service support.

Equipment Features

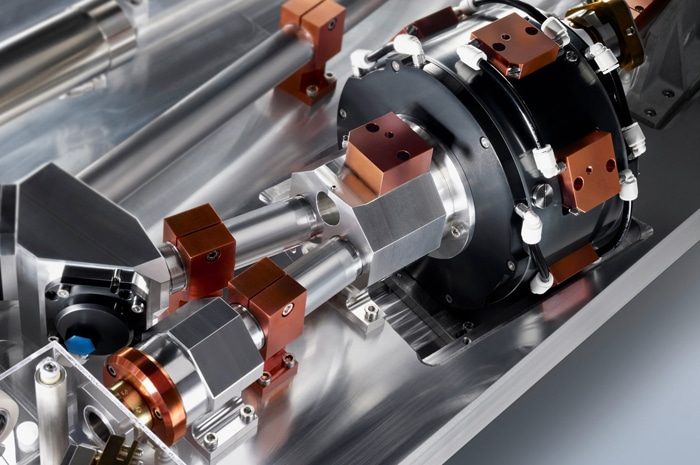

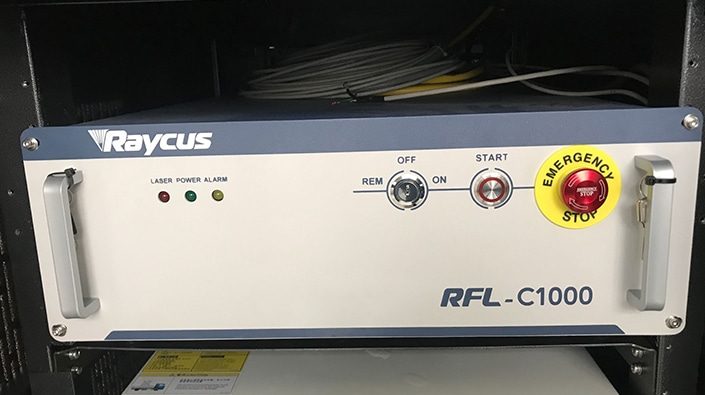

Powerful Laser Generator

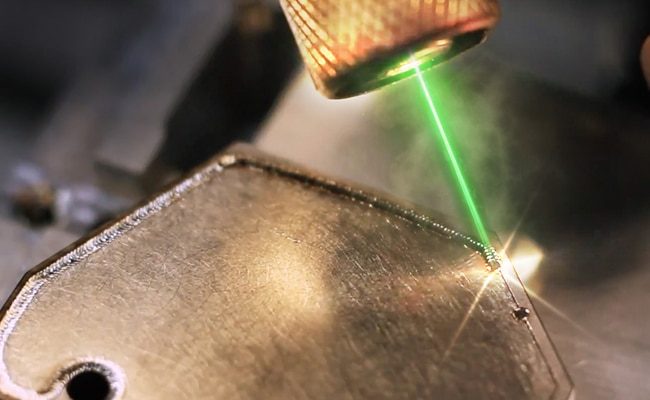

Our laser welding machines are equipped with high-quality laser generators that ensure excellent beam quality, providing small and focused spot sizes for precise and efficient welding. With power output options from 1000w to 3000w, our laser welding machines can meet a variety of welding needs, ensuring optimum productivity without compromising quality.

Advanced Cooling System

Designed with reliability in mind, our laser welding machines feature an efficient water cooling system to ensure consistent performance and extend the life of the laser generator. With advanced water cooling technology, we can guarantee stable and reliable welding results even during long-term operation.

Excellent Beam Quality

Our laser welding machines have excellent beam quality, producing a focused and precise laser spot. This feature enables high-precision and efficient welding of different materials and thicknesses, reducing spatter and minimizing the heat-affected zone.

Precision Beam Delivery System

The beam delivery system of our laser welding machines utilizes flexible and flexible fiber optic cables, which can be easily integrated into automated production lines or robotic systems, enabling you to flexibly and easily adapt to different welding tasks. This flexibility increases workflow efficiency and seamlessly adapts to various manufacturing settings.

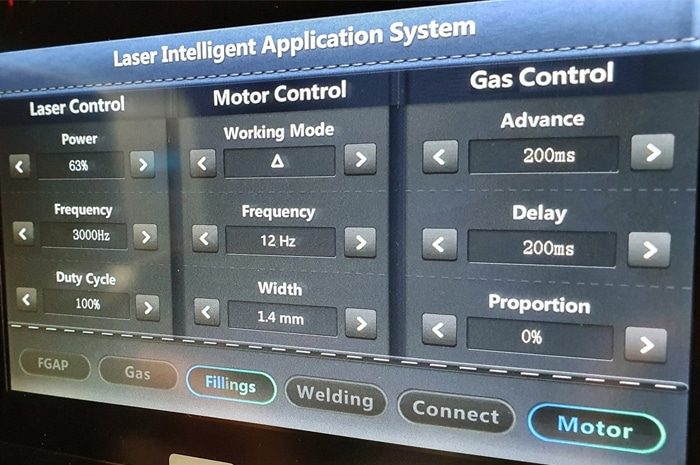

Intuitive Control Interface

Our laser welding machines feature a user-friendly control interface that gives you complete control over your welding process. Easily adjust and program welding parameters such as power, pulse duration, welding speed, and focus position to obtain the best results for your specific welding requirements.

Comprehensive Security Features

Our laser welding machines are equipped with comprehensive safety features including enclosures, interlock systems, and safety sensors. These measures protect your operators from potential exposure to the laser beam, creating a safe work environment.

Technical Specifications

| Model | AKH-1000 | AKH-1500 | AKH-2000 | AKH-3000 |

|---|---|---|---|---|

| Laser Power | 1000W | 1500W | 2000W | 3000W |

| Laser Type | Fiber laser | |||

| Range of Adjustable Power | 1-100% | |||

| Laser Wavelength | 1064nm | |||

| Way of Workinging | Continuous/Modulation | |||

| Speed Range | 0-120mm/s | |||

| Repeat Precision | ±0.01mm | |||

| Welding Gap Requirements | ≤0.5mm | |||

| Cooling Water | Industrial thermostatic water tank | |||

Laser Welding Capacity

| Laser Power (W) | Thickness (mm) | Welding Method | Welding Speed (mm/s) | Defocus Amount | Protective Gas | Blowing Method | Flow (L/min) | Welding Effect |

|---|---|---|---|---|---|---|---|---|

| 1000 | 0.5 | Conduction | 50~80 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 5~10 | Smooth and consistent welds with minimal spatter and distortion. Good penetration. |

| 1 | Conduction | 40~60 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 5~10 | ||

| 1.5 | Conduction | 30~50 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 5~10 | ||

| 2 | Conduction | 20~40 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 5~10 | ||

| 3 | Conduction | 20~30 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 5~10 | ||

| 4 | Conduction | 15~25 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 5~10 | ||

| 5 | Conduction | 10~20 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 5~10 | ||

| 1500 | 0.5 | Conduction | 60~90 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 6~12 | |

| 1 | Conduction | 50~80 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 6~12 | ||

| 1.5 | Conduction | 40~60 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 6~12 | ||

| 2 | Conduction | 30~50 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 6~12 | ||

| 3 | Conduction | 25~40 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 6~12 | ||

| 4 | Conduction | 20~30 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 6~12 | ||

| 5 | Keyhole | 15~25 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 6~12 | Adequate penetration and weld strength. Control heat input to prevent distortion. | |

| 6 | Keyhole | 10~20 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 6~12 | ||

| 2000 | 0.5 | Conduction | 80~100 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 8~15 | |

| 1 | Conduction | 60~90 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 8~15 | ||

| 1.5 | Conduction | 50~80 | -1~1 | Argon or Helium | Coaxial/Paraaxial | 8~15 | ||

| 2 | Keyhole | 40~60 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 8~15 | ||

| 3 | Keyhole | 30~50 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 8~15 | ||

| 4 | Keyhole | 25~40 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 8~15 | ||

| 5 | Keyhole | 20~30 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 8~15 | Deep penetration with well-defined keyhole. Monitor welding speed to avoid overheating. | |

| 6 | Keyhole | 15~25 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 8~15 | ||

| 3000 | 0.5 | Keyhole | 90~120 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 10~18 | |

| 1 | Keyhole | 80~110 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 10~18 | ||

| 1.5 | Keyhole | 60~90 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 10~18 | ||

| 2 | Keyhole | 50~80 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 10~18 | ||

| 3 | Keyhole | 40~60 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 10~18 | ||

| 4 | Keyhole | 30~50 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 10~18 | ||

| 5 | Keyhole | 25~40 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 10~18 | ||

| 6 | Keyhole | 20~30 | -2~2 | Argon or Helium | Coaxial/Paraaxial | 10~18 |

- In the welding data, the core diameter of the 1000w, 1500w, 2000w, and 3000w laser output fiber is 50 microns.

- This welding data adopts the Raytools welding head, and the optical ratio is 100/200 (collimator/focus lens focal length).

- The welding shielding gas: Argon (purity 99.99%).

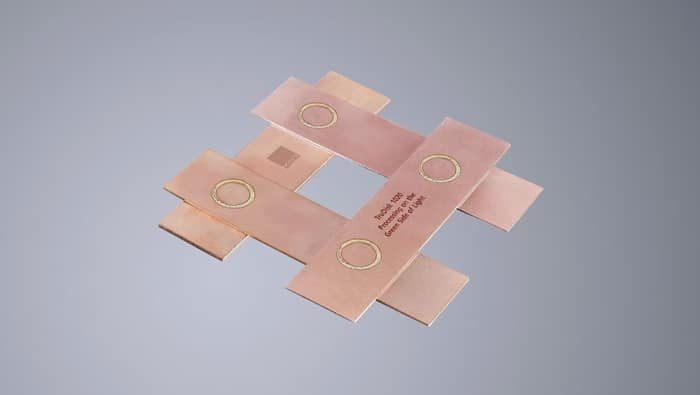

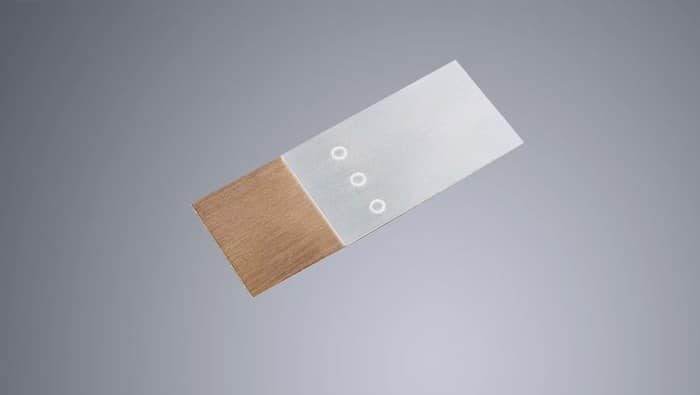

- The welding material is copper.

- Due to the differences in equipment configuration and welding process used by different customers, this data is for reference only.

Comparison of Different Welding Methods

| Welding Process | Laser Welding | TIG Welding | MIG Welding |

|---|---|---|---|

| Heat Source | Laser beam | Tungsten inert gas (TIG) arc | Metal inert gas (MIG) arc |

| Welding Speed | High | Moderate to high | High |

| Precision | Very high | High | Moderate |

| Control | Excellent | Good | Fair |

| Automation | Easily automated | Manual operation | Easily automated |

| Heat Affected Zone (HAZ) | Small | Small to moderate | Moderate to large |

| Filler Material | Sometimes requires filler wire | Usually requires filler rod/wire | Requires filler wire |

| Shielding Gas | May use inert gas for some applications | Inert gas (e.g., argon) used to shield the arc | Inert gas (e.g., argon) used to shield the arc and feed the filler wire |

| Suitability for Copper | Excellent | Excellent | Good |

| Welding Thickness | Thin to medium | Thin to thick | Thin to thick |

| Weld Quality | High integrity | High integrity | Good to High |

| Skill Level | Advanced | Intermediate to advanced | Beginner to intermediate |

| Equipment Cost | High | Moderate to high | Moderate |

Product Features

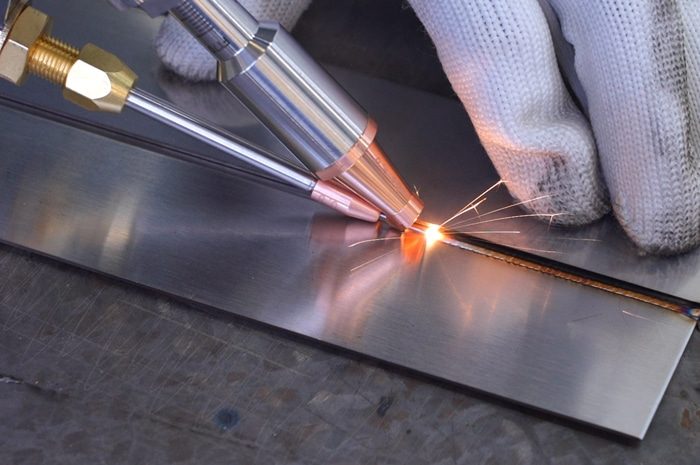

- The machine is equipped with a high-power fiber laser generator, which has the characteristics of high energy efficiency, excellent beam quality, and precise control of laser beam parameters. Fiber laser generators are capable of delivering high-powered, focused laser energy, making them ideal for welding copper.

- The machine provides excellent beam quality, ensuring that the laser beam is focused and stable, resulting in precise, high-quality welding results.

- The machine can precisely control the laser power and pulse duration, so as to make the best adjustment according to the specific welding requirements of copper materials. This precise control ensures consistent and high-quality welds.

- The intuitive and user-friendly interface makes it easier for the operator to set welding parameters, monitor the welding process and adjust settings as needed.

- The machine has an efficient cooling system, which can maintain the best working temperature of the laser generator and prevent overheating during long-term use.

- The machine provides a variety of laser power options to meet different copper thicknesses and welding requirements.

- The machine selects a high-quality beam transmission system, which can effectively transmit the laser beam from the laser generator to the welding area, ensuring the stability, accuracy, and consistency of the laser beam during the welding process.

- The machine is easy to maintain and maintain, with features such as easy access to key components, diagnostic tools, and remote monitoring functions to ensure smooth operation and minimize downtime.

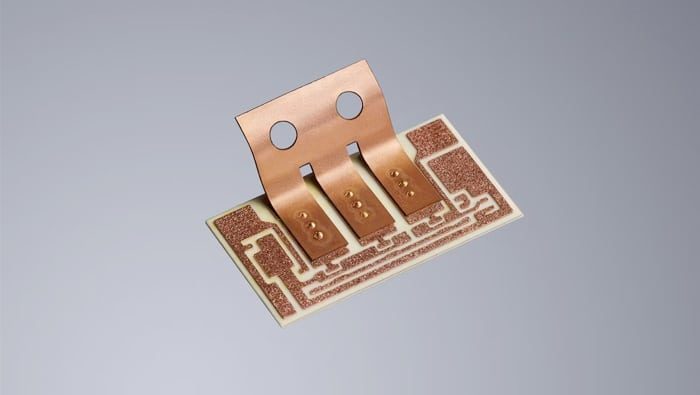

Product Application

Equipment Selection

High-Configuration Fiber Laser Welding Machine

Portable Fiber Laser Welding Machine

Fiber Laser Welding Machine With Double Wobble

Fiber Laser Welding Machine With Automatic Wire Feeder

3 In 1 Fiber Laser Welding Cutting Cleaning Machine

Laser Welding Robot

Portable Air-Cooled Laser Welding Machine

Why Choose AccTek?

Unparalleled Expertise

Comprehensive Support And Service

Strict Quality Control

Cost-Effective Solution

Frequently Asked Questions

- Argon (Ar): Argon is the most commonly used shielding gas when laser welding copper. It is an inert gas, which means it does not react with copper or the surrounding atmosphere. During laser welding, argon gas is directed around the weld area to create a protective atmosphere that protects the molten copper from the surrounding air (which contains oxygen). This prevents oxidation and ensures a clean and stable weld. Argon is versatile and relatively cost-effective compared to helium.

- Helium (He): Helium can also be used as a shielding gas for laser welding copper. It has a higher thermal conductivity than argon, allowing it to carry heat away from the weld area more effectively. Helium’s higher thermal conductivity helps offset the challenges posed by copper’s high thermal conductivity. However, helium is generally more expensive than argon, which may influence its choice in some applications.

- High Thermal Conductivity: Copper is one of the most thermally conductive of common metals. This means that it quickly conducts heat away from the welded area, making it difficult to reach the temperature required for successful fusion. Therefore, greater laser power and precise control are required to maintain the heat required to melt copper.

- High Reflectivity: Copper is highly reflective of infrared radiation, which includes the wavelengths used in most laser welding processes. This reflection reduces the laser’s effectiveness, reduces the amount of energy absorbed by the material, and makes it harder to reach the necessary melting point.

- Low Absorption of Laser Energy: Copper has a relatively low absorption coefficient for laser light, which means that copper absorbs laser energy less readily than other metals. This results in the need for higher laser power to achieve the energy required for welding.

- Oxidation Sensitivity: Copper is susceptible to oxidation when exposed to air at elevated temperatures. During laser welding, molten copper reacts easily with oxygen, leading to the formation of unwanted oxides. These oxides can weaken the weld and affect weld quality and conductivity.

- Surface Preparation: Achieving a clean and oxide-free surface is critical to successful brazing. Any contamination or oxide layer on the copper surface will interfere with the soldering process, making it more difficult to achieve a strong and defect-free solder joint.

- Precise Beam Control: Laser welding requires precise beam focusing and control for precise and consistent welds. Copper’s high thermal conductivity and reflectivity require more precise control to maintain the correct temperature and avoid overheating or underheating of the material.