$11,800.00 – $30,800.00

The beam is manufactured according to the aerospace standard. Compared with the steel beam, the weight is greatly reduced, the load of the servo motor is reduced, and the inertia is reduced. After aging treatment, the beam has the characteristics of lightweight, high strength, and high running precision. The lightweight beam can ensure the fast operation of the equipment, improve the processing efficiency, and ensure the processing quality at the same time.

The internal structure of the bed is welded by multiple rectangular tubes, and there are reinforced rectangular tubes inside the bed to enhance the strength and stability of the body. The solid body structure not only increases the stability of the guide rail but also effectively prevents the deformation of the body. The service life of the body is as long as 25 years.

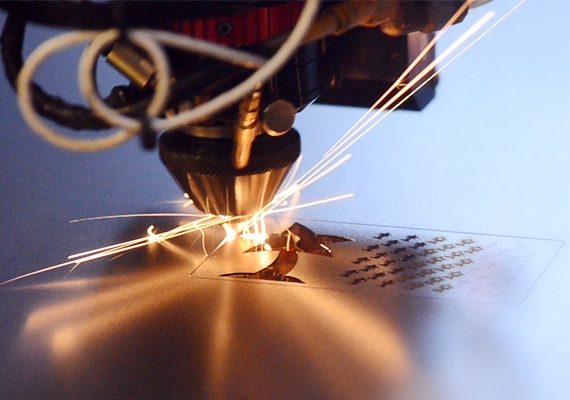

The laser source used by the machine is a professional fiber laser generator, which is famous for its excellent beam quality, energy efficiency, and long service life. The fiber laser generator is housed in a rugged housing that provides stable and reliable operation even in harsh industrial environments.

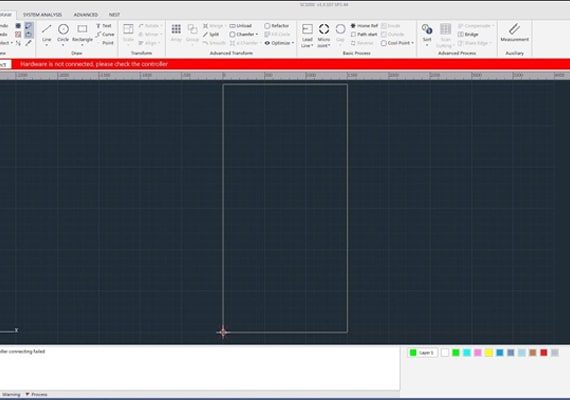

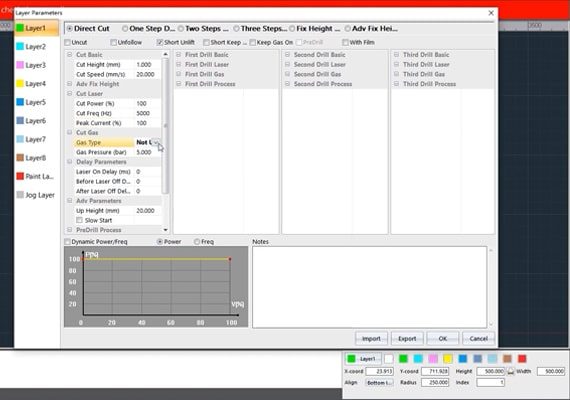

Adopt Au3tech SC2000 laser cutting system, human-computer interaction, simple, economical, practical, and convenient. The cutting system has a rich built-in fiber laser cutting process and its parameters are highly integrated, highly intelligent, and integrate file reading, design, output, and processing control.

The operation screen adopts a vertical screen design, which is different from the traditional horizontal screen display, with fast response speed, higher contrast, wider field of view, low power consumption, and high resolution. In addition, the operating screen features high brightness and low reflectivity, as well as a durable solid glass panel.

Our selection of Taiwan Delta servo motors can not only meet the high-precision positioning requirements of the laser cutting machine but also reduce maintenance and wiring costs for multi-function operations.

| Model | AKJ-1325F1 | AKJ-1530F1 | AKJ-2040F1 | AKJ-2560F1 |

| Cutting Range | 1300*2500mm | 1500*3000mm | 2000*4000mm | 2500*6000mm |

| Laser Type | Fiber Laser | |||

| Laser Power | 1500-3000W | |||

| Transmission System | Gantry Double Drive Structure | |||

| Maximum Moving Speed | 100m/min | |||

| Maximum Acceleration | 1.0G | |||

| Positioning Accuracy | ±0.01mm | |||

| Repeat Positioning Accuracy | ±0.03mm | |||

Adopt high-speed digital motion control of a German technology system, especially suitable for high-speed and high-precision laser cutting.

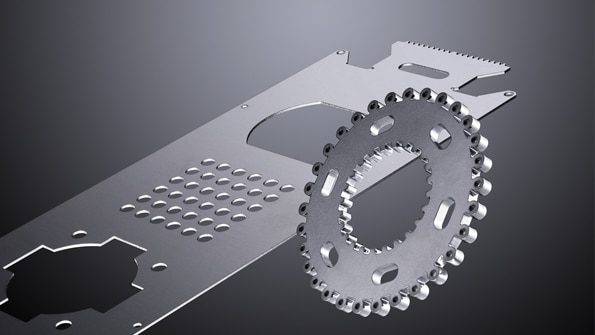

The slit of the fiber laser cutting machine is very narrow, the lowest can reach 0.05mm, which is very suitable for the high-efficiency processing of precision parts.

The automatic mechanical lubrication system can lubricate the linear guide rail nearly 500 times per minute to ensure the high-precision operation of the laser cutting machine.

The gantry structure with synchronous bilateral rack and pinion transmission and high-strength aluminum beams are adopted to improve the stability of the equipment.

The photoelectric conversion efficiency of the laser generator is as high as 25-30%, which can effectively save energy use.

The stable cutting table has a long service life and can be used for 25 years without deformation.

The cutting surface is smooth, without burrs, and does not require secondary processing by workers, saving time and effort.

The fiber laser cutting machine does not require a lens, which greatly reduces maintenance costs. The life of key components can reach 100,000 hours, and the performance is stable and reliable.

| Material Type | 1000W | 1500W | 2000W | 3000W |

| Carbon Steel (O2) | 1-10mm | 1-14mm | 1-16mm | 1-20mm |

| Carbon Steel (AIR) | / | / | 1-3mm | 1-3mm |

| Carbon Steel (N2) | / | / | 1-3mm | 1-3mm |

| Stainless Steel (N2) | 1-5mm | 1-6mm | 1-8mm | 1-12mm |

| Stainless Steel (AIR) | 1-5mm | 1-6mm | 1-8mm | 1-12mm |

| Aluminum Alloy (N2) | 1-3mm | 1-6mm | 1-8mm | 1-12mm |

| Aluminum Alloy (AIR) | 1-3mm | 1-6mm | 1-8mm | 1-8mm |

| Brass (N2) | / | / | 1-4mm | 1-6mm |

| Copper (O2) | / | / | 1-2mm | 1-3mm |

Yes, the above price is indeed the FOB price for a laser cutting machine with a cutting area of 1500×3000mm. Please note that if you require a different cutting area, this may affect the price. Adjustments in the machine’s size often impact the overall cost due to changes in material usage, machine configuration, and shipping requirements. If you have specific needs regarding the cutting area, we would be happy to provide an updated quotation based on those dimensions.

The AKJ-F1 laser cutting machine offers three power options to meet different cutting needs: 1500W, 2000W, and 3000W. These options allow flexibility for various materials and thicknesses, depending on your production requirements.

If you are considering higher power for cutting thicker materials or for increased efficiency, we recommend exploring the AKJ-F2 or AKJ-F3 laser cutting machines. These models are designed to handle more demanding applications and come with additional power options beyond 3000W.

Please let us know if you’d like more details on the AKJ-F2 or AKJ-F3 models, and we can provide a comparison to help you choose the best machine for your needs.

The laser cutting machine is versatile and capable of cutting a wide range of metal materials, making it suitable for various applications. It can effectively cut:

These material options make the machine highly adaptable for diverse industries, including metal fabrication, automotive, aerospace, electronics, and construction. If you have specific thickness requirements for any of these materials, we can provide further details on cutting capabilities and power settings.

Our laser cutting machine package includes comprehensive technical support options designed to ensure smooth operation and help you maximize machine efficiency. We offer:

Both support options are aimed at helping you achieve the best possible results with your machine. Please let us know if you’d like further details or if you’re interested in arranging on-site training.

Our laser cutting machine is backed by a comprehensive warranty designed to give you peace of mind and protect your investment:

Please note that this warranty excludes damage resulting from improper use, mishandling, or other artificial causes.

Our laser-cutting machine is certified with internationally recognized standards to ensure quality, safety, and compliance with industry requirements.

If additional certifications are required for specific regions or industries, please let us know, and we can provide further information.

Yes, all our laser cutting machines are equipped with an auto-focus feature to enhance cutting precision and ease of operation.

The auto-focus capability automatically adjusts the focal distance of the laser beam based on the material thickness and type. This feature is especially beneficial for users who work with various materials or need to switch between different thicknesses frequently. By automatically optimizing the focus, the machine ensures consistent, high-quality cuts without the need for manual adjustments, which saves time and minimizes errors.

Additionally, the auto-focus function enhances cutting efficiency, allowing for faster processing speeds and reducing setup time. This feature is ideal for both intricate designs and high-volume production, ensuring precise results across all types of materials. If you have specific applications in mind, we would be happy to discuss how the auto-focus feature can improve your workflow.

Our laser-cutting machine system supports a variety of file formats, including DXF, AI, PLT, SVG, PDF, and DWG. These formats ensure compatibility with popular design and CAD software, making it easy to import and work with detailed drawings, vector designs, and technical files. If you have any additional format requirements, feel free to let us know, and we can verify compatibility.

With years of experience in laser cutting technology, we have honed our expertise to provide cutting-edge solutions tailored to your unique needs. Our team of skilled engineers and technicians has the in-depth knowledge to ensure you get the perfect laser-cutting machine for your specific application.

At AccTek Laser, we build strong relationships with our clients. Our dedicated support team provides prompt assistance and after-sales service to keep your laser-cutting machine running at its best for years to come. Your satisfaction is our top priority and we will help you every step of the way.

Quality is the cornerstone of our manufacturing process. Every laser-cutting machine is rigorously tested and adheres to strict quality control standards, ensuring that the product you receive meets the highest industry benchmarks. Our dedication to quality ensures you get a machine that performs consistently and delivers perfect cuts every time.

We understand the importance of cost efficiency in today’s competitive landscape. Our laser-cutting machines can provide excellent value for your investment, minimizing downtime and reducing operating costs while maximizing productivity and efficiency.

4 reviews for AKJ-F1 Laser Cutting Machine

Ori –

Dependable and precise, this fiber laser machine has become an essential part of our operations. It’s efficient, reliable, and delivers consistent results.

Jack –

Highly satisfied with the cutting quality and speed of this fiber laser cutting machine. It’s efficient, reliable, and has boosted our productivity.

Emily –

Exceptional performance from this fiber laser machine. It’s robust, efficient, and delivers high-quality cuts consistently, improving our workflow.

Katarzyna –

This fiber laser cutting machine is exceptional. It’s fast, versatile, and easy to use, making it a valuable asset for our manufacturing process.