Tube Laser Cutting Machine

Product Range

-

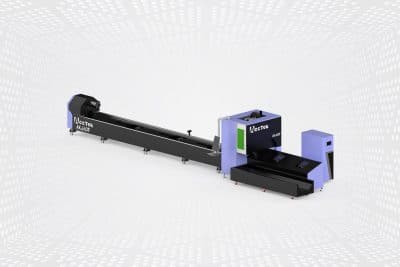

AKJ60F Laser Cutting Machine

Rated 4.75 out of 5$24,700.00 – $74,800.00Price range: $24,700.00 through $74,800.00 Select options This product has multiple variants. The options may be chosen on the product page -

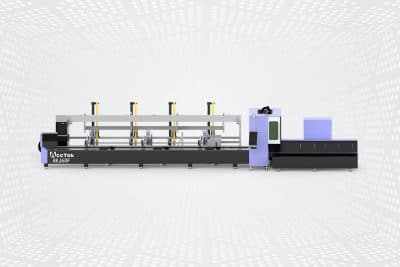

AKJ60FA Laser Cutting Machine

Rated 4.75 out of 5$76,700.00 – $126,800.00Price range: $76,700.00 through $126,800.00 Select options This product has multiple variants. The options may be chosen on the product page

Optional Tube Laser Cutting Machine Power

Materials That Can Be Cut

Laser Cutting VS. Other Methods

Laser Cutting vs. Mechanical Cutting

Laser cutting offers smoother, more precise cuts than mechanical cutting, which often leaves rough edges and requires additional finishing. Unlike mechanical cutting, there’s no tool wear in laser cutting, and it can handle complex geometries with minimal waste.

Laser Cutting vs. Water Jet Cutting

While water jet cutting is ideal for thicker materials, laser cutting is faster, more accurate, and cost-effective for thin tubes. Laser cutting also produces cleaner cuts with less distortion, reducing the need for post-processing when compared to the slower and more labor-intensive water jet process.

Laser Cutting vs. Plasma Cutting

Plasma cutting is faster than laser cutting, but it leaves rough edges and a larger heat-affected zone. Laser cutting provides higher precision, smoother edges, and less material distortion, making it ideal for industries that require fine details and high-quality results, especially in tube cutting.

Why Choose AccTek Laser

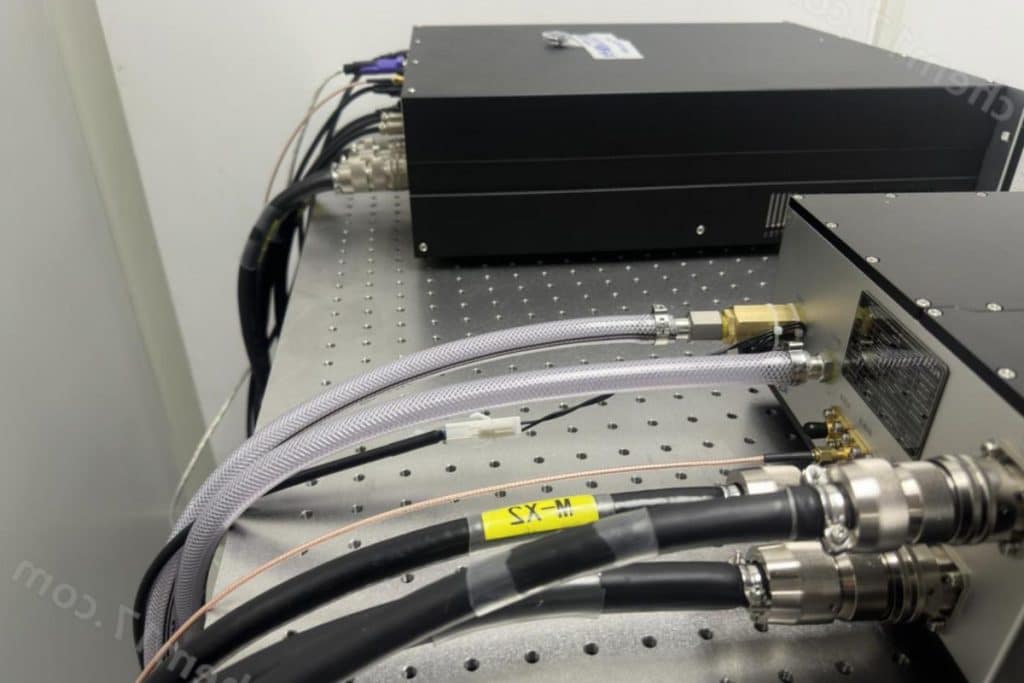

Cutting-Edge Technology

AccTek Laser machines utilize the latest laser technology, ensuring high precision and fast cutting speeds. Our systems provide unmatched accuracy and efficiency, ensuring the best quality cuts across various materials with minimal distortion.

Custom Solutions

We understand that every business has unique requirements. That's why we offer customizable options, including power ranges, work area sizes, and cutting speeds, allowing you to tailor our machines to fit your specific production needs and material types.

Exceptional Energy Efficiency

Our laser cutting machines are designed for maximum energy efficiency. With lower power consumption and optimized performance, AccTek Laser machines help reduce operational costs, making them a cost-effective solution for both small and large-scale manufacturing.

Durability and Reliability

AccTek Laser cutting machines are engineered for long-term durability, with high-quality components and precision manufacturing. Our machines are designed to provide consistent, reliable performance, reducing maintenance needs and extending the lifespan of your equipment.

After-Sales Support

We believe in building long-term relationships with our customers. AccTek Laser provides exceptional after-sales support, including installation, training, and ongoing technical assistance. Our team is always ready to help you optimize machine performance and resolve any issues quickly.

Competitive Pricing and Value

At AccTek Laser, we offer high-performance laser-cutting machines at competitive prices, ensuring that you get the best value for your investment. Our machines deliver outstanding quality at an affordable cost, making us a trusted partner for your manufacturing needs.

Frequently Asked Questions

What Are Tube Laser Cutting Machines?

What Is The Price Of Tube Laser Cutting Machines?

- Entry-level models with basic capabilities may start at around $25,000 to $45,000. These machines typically have lower power levels, smaller cutting capacities, and fewer advanced features.

- Mid-range tube laser cutting machines with higher power levels, larger cutting capacities, and more features typically range from $50,000 to $100,000.

- High-end or industrial-grade tube laser cutting machines, which offer the highest power levels, largest cutting capacities, advanced automation features, and customization options, can cost upwards of $150,000 to $500,000. It’s important to note that in addition to the initial purchase price, there may be additional costs for installation, training, maintenance, and ongoing operational expenses such as electricity and consumables like laser gases and replacement parts.

What Is The Maximum Tube Diameter And Length That Tube Laser Cutting Machines Can Cut?

What Shapes Of Tubes Can Tube Laser Cutting Machines Cut?

- Round Tubes: These are cylindrical tubes with a circular cross-section and are among the most commonly cut shapes.

- Square Tubes: These tubes have a square cross-section, with four equal sides meeting at right angles.

- Rectangular Tubes: Similar to square tubes, rectangular tubes have a rectangular cross-section, with two pairs of opposite sides equal in length and meeting at right angles.

- Oval Tubes: Oval tubes have an elliptical cross-section, providing a unique aesthetic and functional profile.

- Triangular Tubes: Triangular tubes have three sides and are shaped like triangles when viewed in cross-section.

- Hexagonal Tubes: These tubes have a hexagonal cross-section with six equal sides and angles.

- Custom Profiles: Depending on the machine’s capabilities and the software used for programming, tube laser cutting machines can also cut custom profiles and shapes to meet specific design requirements.

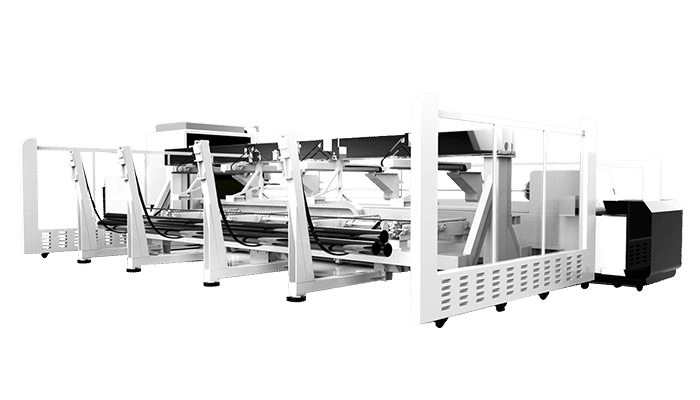

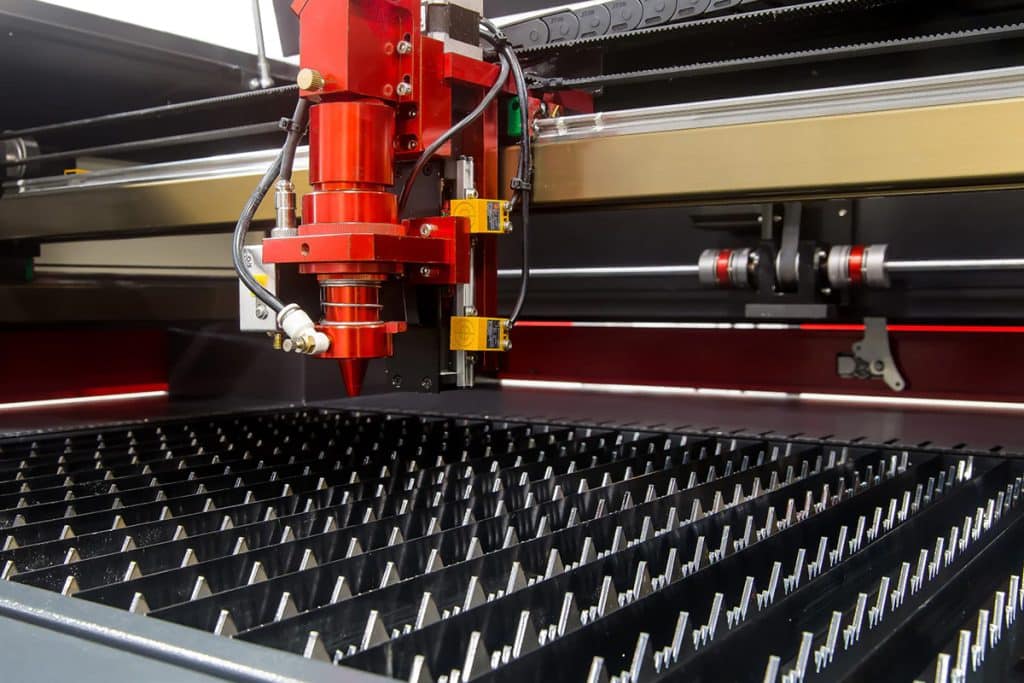

How Do Tube Laser Cutting Machines Work?

- Material Loading: Tubes or pipes are loaded onto the machine’s bed, usually through a feeding system that positions the material for cutting. Some machines may have automatic loading mechanisms to streamline this process.

- Material Fixation: The tube is securely clamped or held in place to prevent movement during cutting. This ensures accuracy and consistency in the cut.

- Programming: An operator or technician programs the machine using specialized software. This involves specifying the desired cutting parameters, such as the dimensions, shape, and cutting path.

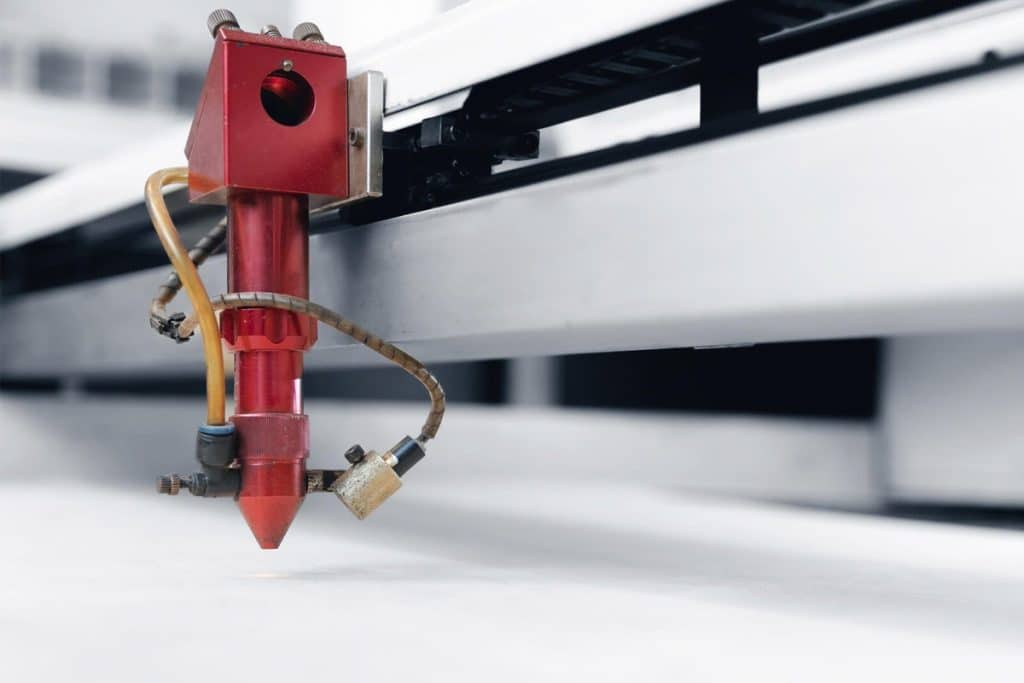

- Laser Cutting: The machine uses a high-powered laser beam, typically generated by a fiber laser source, focused through a lens. The laser beam is directed onto the surface of the tube, where it melts, burns, or vaporizes the material along the programmed cutting path.

- Computer Control: The cutting process is controlled by a computerized system, which precisely guides the laser along the programmed cutting path. This ensures accurate and consistent cuts according to the specified design.

- Cooling and Extraction: As the laser cuts through the material, heat is generated. Cooling systems, such as water or air jets, may be used to prevent laser head overheating and ensure the quality of the cut. Additionally, extraction systems remove fumes and debris generated during the cutting process to maintain a clean working environment.

- Unloading: Once the cutting process is complete, the finished parts are unloaded from the machine. Depending on the setup, this may be done manually or through an automated system.

- Quality Control: The cut tubes are inspected for accuracy, quality, and consistency to ensure they meet the specified requirements.

How To Maintain Tube Laser Cutting Machines?

- Regular Cleaning: Keep the machine clean by removing dust, debris, and residue from the cutting area, lenses, mirrors, and other components. Use compressed air, brushes, or specialized cleaning solutions as recommended by the manufacturer.

- Lubrication: Lubricate moving parts, such as rails, bearings, and drive systems, according to the manufacturer’s guidelines. This helps reduce friction, wear, and tear, extending the lifespan of the machine.

- Inspect Optics: Regularly inspect and clean the laser optics, including lenses and mirrors, to ensure optimal beam quality and cutting performance. Replace any damaged or worn-out components as needed.

- Check Alignment: Periodically check and adjust the alignment of the laser beam delivery system, focusing optics, and cutting head to maintain accurate cutting results.

- Monitor Cooling Systems: Monitor the performance of cooling systems, such as water chillers or air coolers, to ensure proper temperature regulation and prevent overheating of the laser source.

- Inspect Consumables: Check and replace consumable parts, such as nozzles, lenses, and protective windows, regularly to maintain cutting quality and efficiency.

- Software Updates: Keep the machine’s control software up to date by installing the latest updates and patches provided by the manufacturer. This ensures compatibility, reliability, and security improvements.

- Operator Training: Provide ongoing training for machine operators to ensure they understand proper operating procedures, safety protocols, and maintenance tasks.

- Scheduled Maintenance: Follow the manufacturer’s recommended maintenance schedule for routine inspections, lubrication, adjustments, and component replacements. This helps prevent unexpected breakdowns and ensures consistent performance.

- Safety Checks: Regularly inspect safety features, such as emergency stop buttons, interlocks, and laser safety enclosures, to ensure they are functioning correctly and comply with safety standards.

How Do Tube Laser Cutting Machines Reduce Material Waste?

- Narrow Kerf Width: The laser beam used in tube laser cutting machines has a very small diameter, resulting in a narrow kerf width, the width of material removed during cutting. This narrow kerf minimizes the amount of material wasted, as less material is converted to scrap during the cutting process.

- Optimized Nesting: Tube laser cutting machines often incorporate software that optimizes the arrangement of parts on the material to be cut, a process known as nesting. By nesting parts closely together, the software maximizes the utilization of the material, reducing scrap and minimizing waste.

- High Accuracy and Repeatability: Tube laser cutting machines offer high levels of accuracy and repeatability in cutting, ensuring that parts are cut precisely according to the specified dimensions. This accuracy minimizes errors and reduces the need for additional material to compensate for inaccuracies.

- Complex Geometries: The flexibility of tube laser cutting machines allows for the cutting of complex geometries with intricate shapes and contours. This capability enables manufacturers to optimize the design of parts to minimize material usage while still meeting performance requirements.

- Material Utilization: Tube laser cutting machines can cut various materials, including metals, plastics, and composites. By choosing the most suitable material for a given application and optimizing the cutting process, manufacturers can minimize waste and maximize material utilization.

How Do Tube Laser Cutting Machines Reduce The Risk of Tube Deformation?

- Precision Cutting: Tube laser cutting machines use a focused laser beam to cut through the material with extreme precision. This precise cutting process minimizes the heat-affected zone and reduces the risk of thermal distortion or deformation in the cut tubes.

- Stress-Free Cutting: Laser cutting is a non-contact process, which means that the material is not subjected to mechanical forces or stress during cutting. This helps prevent distortion and deformation in the cut tubes, particularly in materials prone to warping under mechanical pressure.

- Automated Control: Tube laser cutting machines are typically equipped with computerized control systems that regulate the cutting parameters, such as laser power, cutting speed, and focus, with high precision. This automated control ensures consistent cutting quality and minimizes variations that could contribute to tube deformation.

- Support Mechanisms: Some tube laser cutting machines incorporate support mechanisms, such as adjustable clamps or fixtures, to stabilize the tubes during cutting. These support mechanisms help minimize vibration and movement, reducing the risk of distortion in the cut tubes.

Related Resources

Can a CO2 Laser Cutting Machine Perform Cutting and Engraving Tasks at the Same Time?

Can CO2 laser cutting machines achieve “multi-purpose use” of precise cutting and fine engraving? This article combines the principle with the functional characteristics of AccTek’s CO2 laser cutting machines to

Do Fiber Laser Generators Lose Power over Time?

This article focuses on the reasons why fiber laser generator power decreases over time and proposes effective strategies to mitigate power loss through high-quality equipment, regular maintenance, and an optimized

How Does a CO2 Laser Cutting Machine Achieve High-Precision Cutting?

This article mainly introduces the principles and key technologies behind the high-precision cutting capabilities of CO2 laser cutting machines, and analyzes their core structural components and advantages.